Solutions

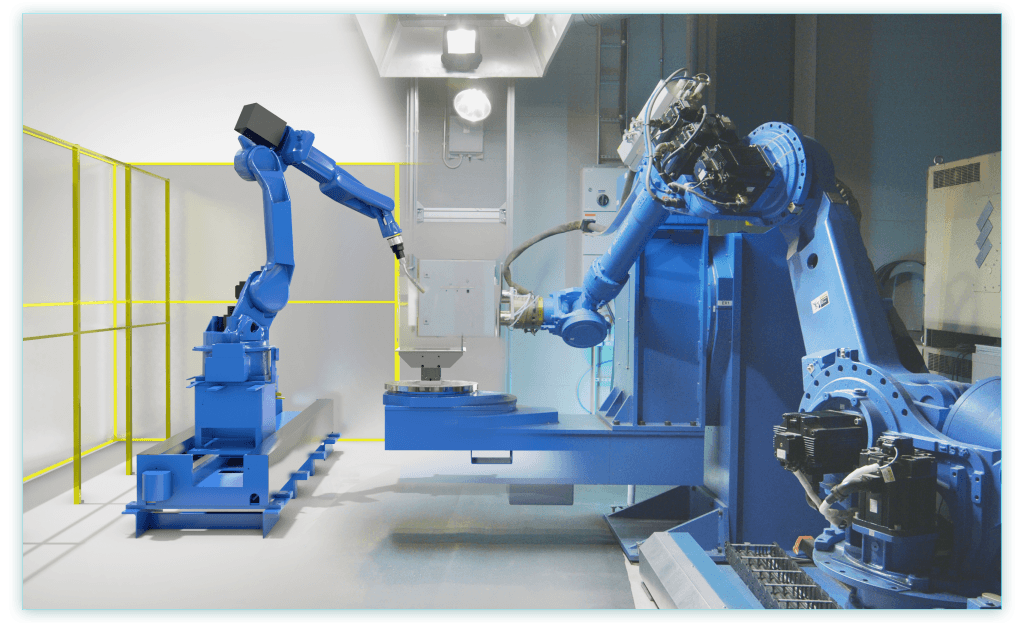

Virtual commissioning

Detect early, resolve fast, enhance efficiency and commission virtually.

Accelerated project timelines

Speed up design-to-deployment, identify and fix issues virtually, bypassing traditional commissioning delays.

Cost reduction

Reduce expenses by minimizing physical prototypes and streamlining on-site testing processes, leading to significant savings.

Enhanced collaboration

Collaborate efficiently with synchronized development and testing, streamlining the commissioning workflow.

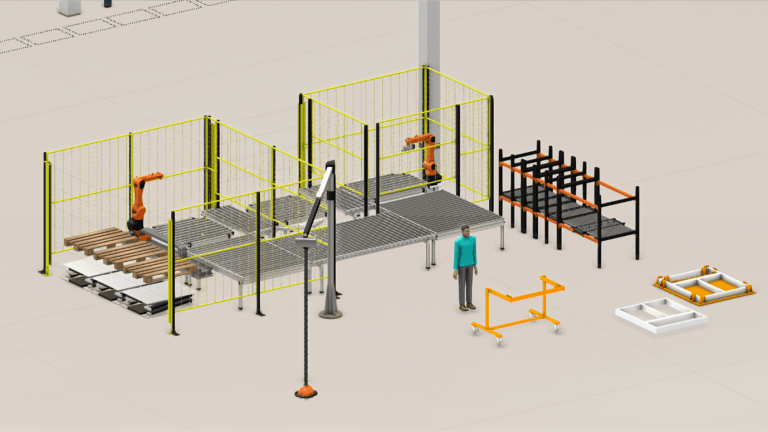

Virtual commissioning in manufacturing

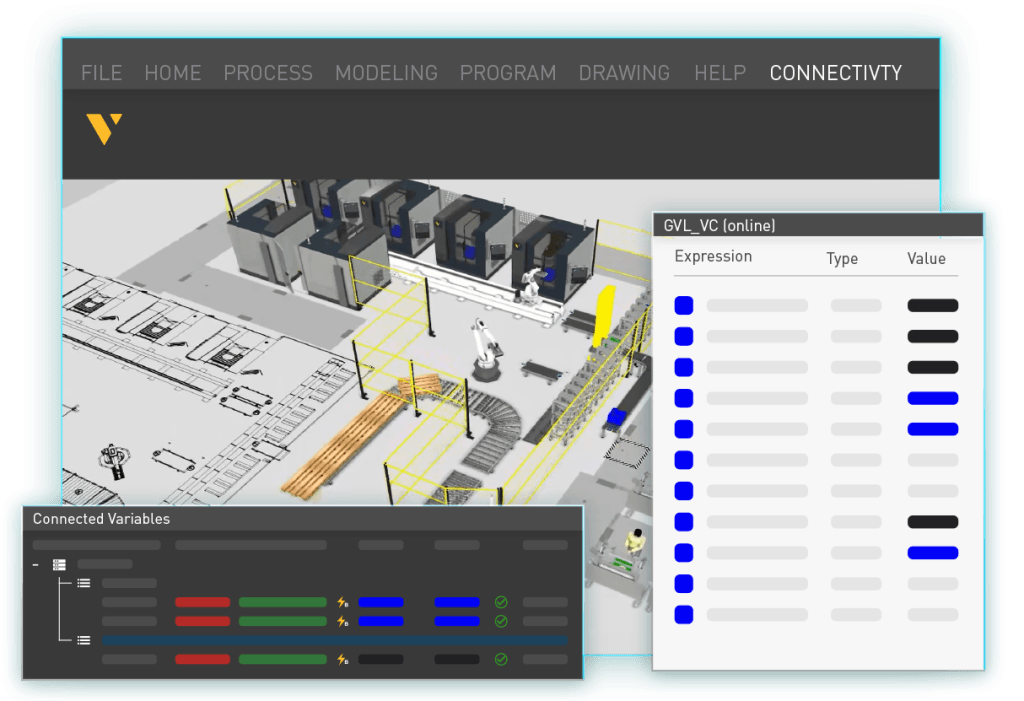

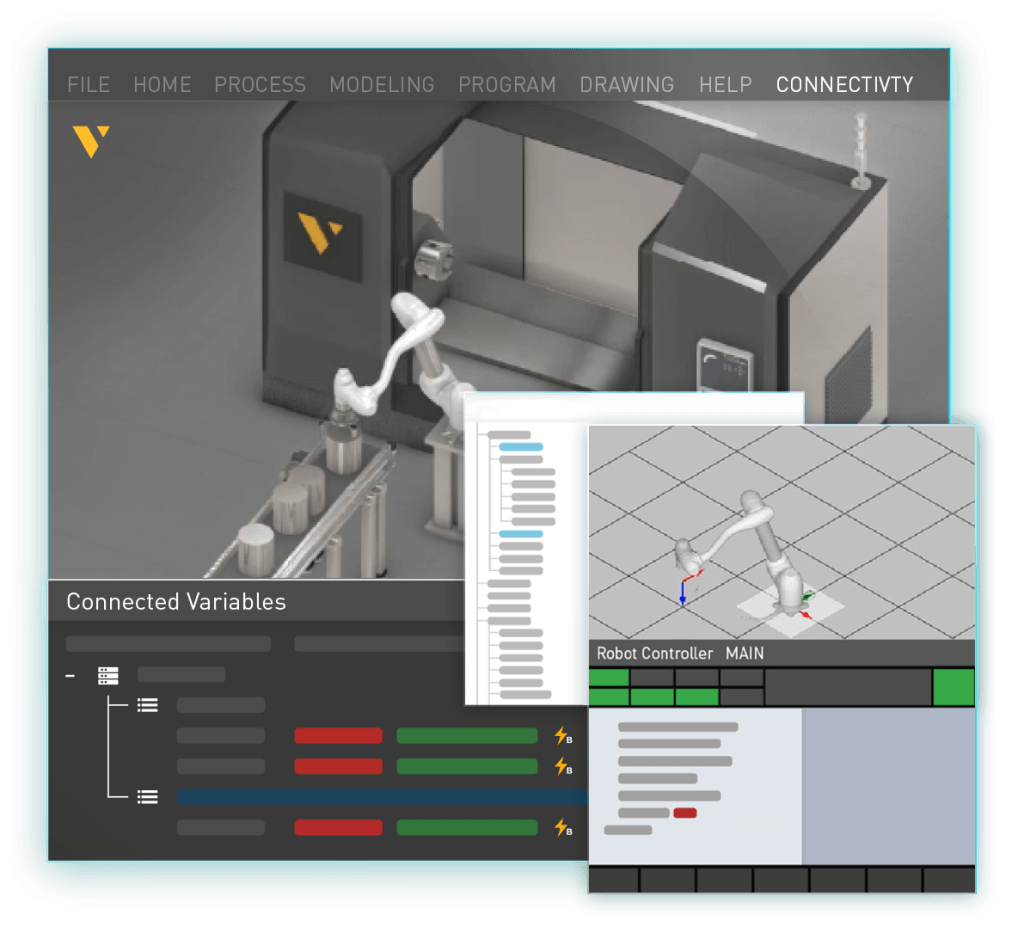

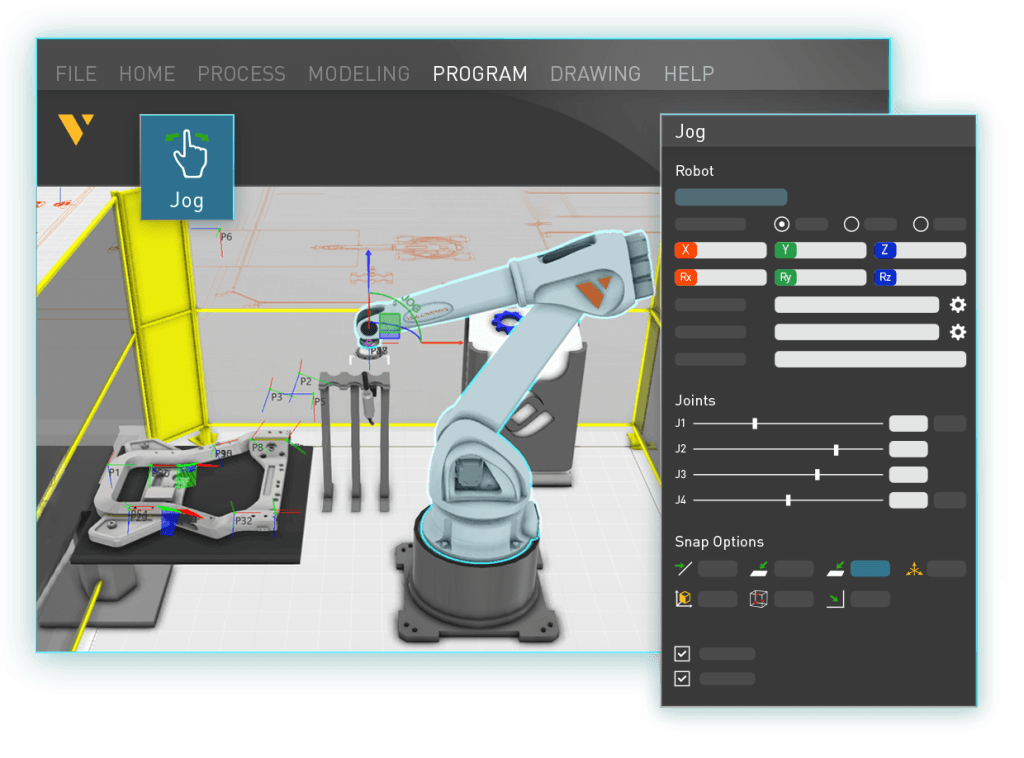

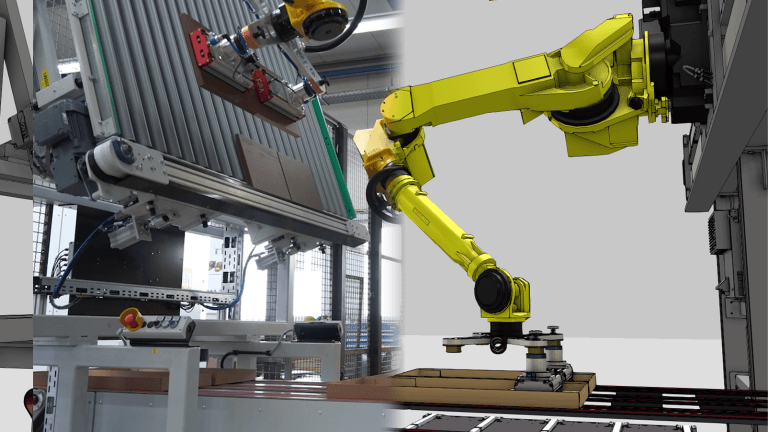

Virtual commissioning is transforming manufacturing by enabling early testing of machines and systems, crucial for meeting factory acceptance testing (FAT) deadlines. This approach reduces delays, costs and compromises, offering a transformative way to test and debug control software. Unlike traditional methods that delay testing until hardware assembly, virtual commissioning allows for earlier control software testing, like in Programmable Logic Controllers (PLCs) and virtual robot controllers, streamlining the commissioning phase and changing the conventional sequence of events.

Process and benefits

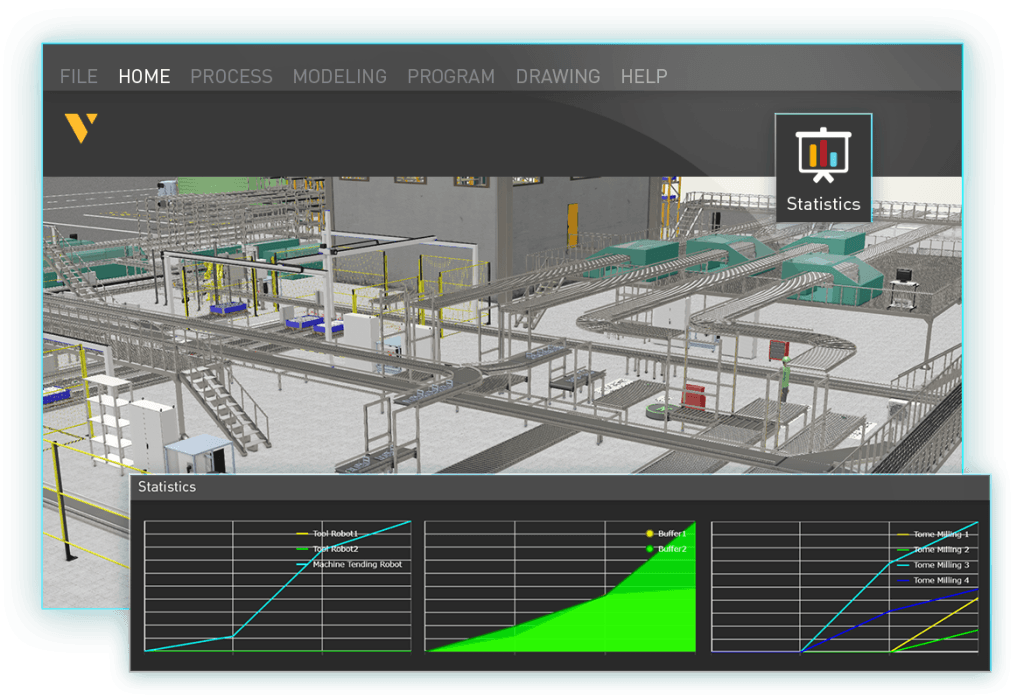

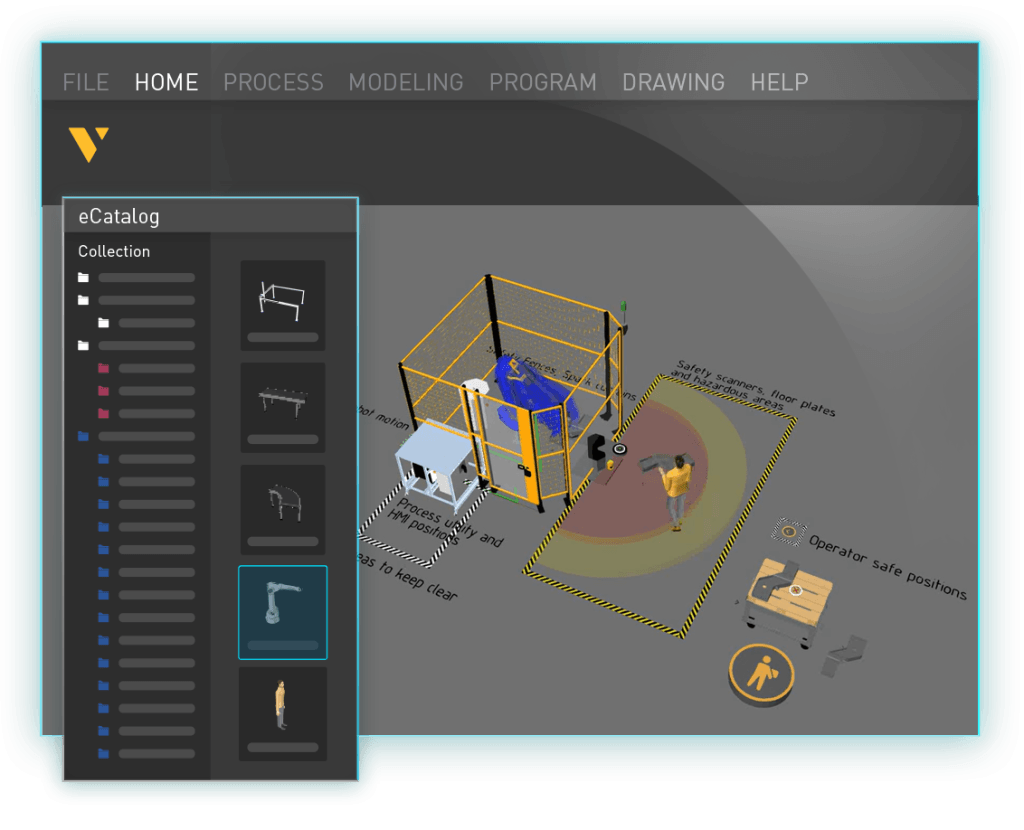

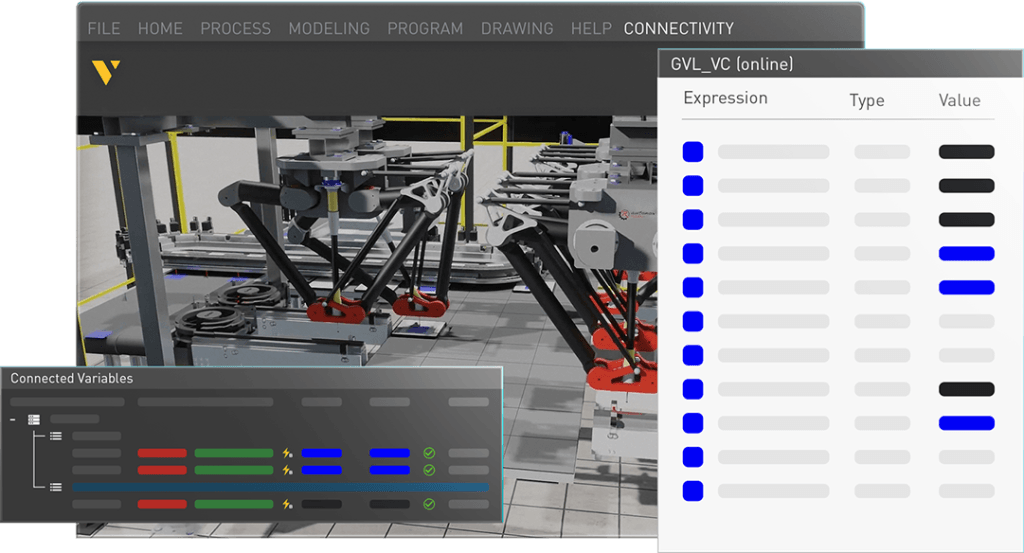

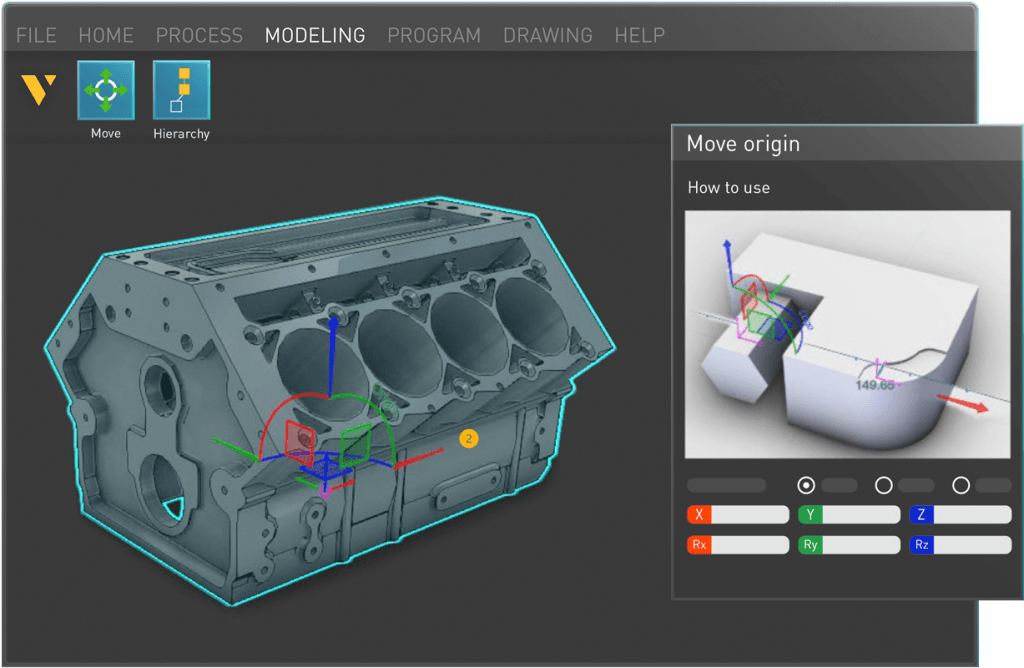

Virtual commissioning begins with a detailed static 3D CAD model, incorporating motion dynamics and control systems. This process, different from digital twins, brings benefits like increased efficiency, cost savings, enhanced safety and quality, and collaborative work environments.

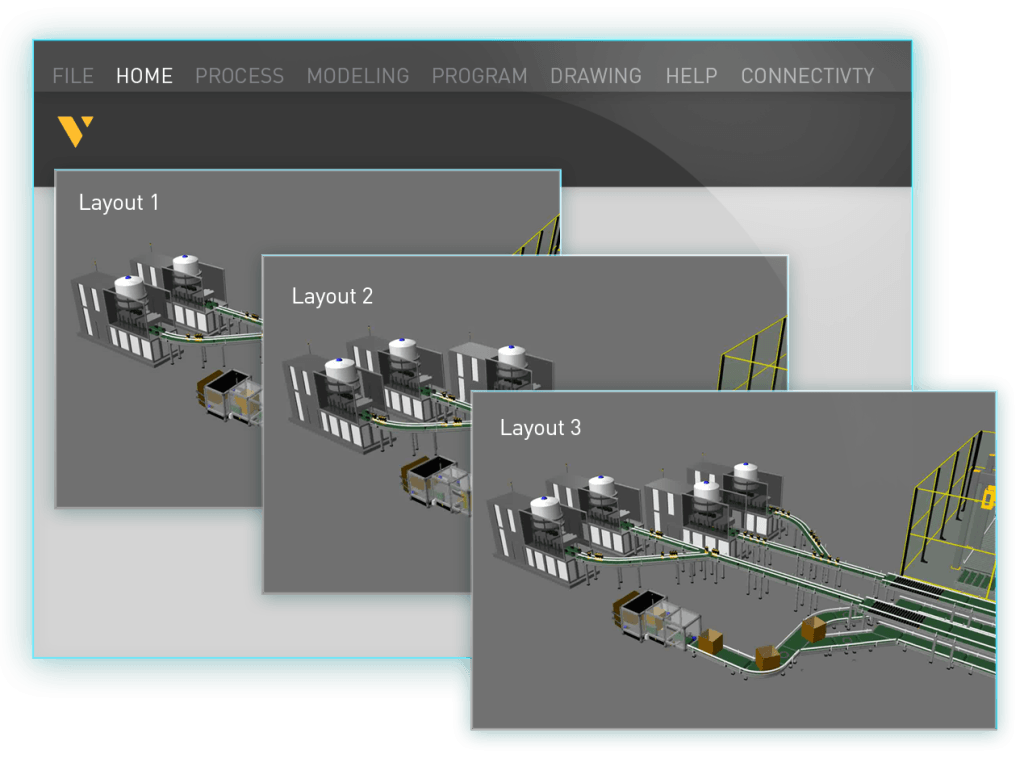

It is useful in various manufacturing applications, from automation to complex packaging simulations. The comprehensive process includes developing a virtual model, system analysis, integrating kinematic and electrical data, control logic, simulations, robotics optimization and iterative refinements for optimal performance.

The role of virtual commissioning in digital transformation

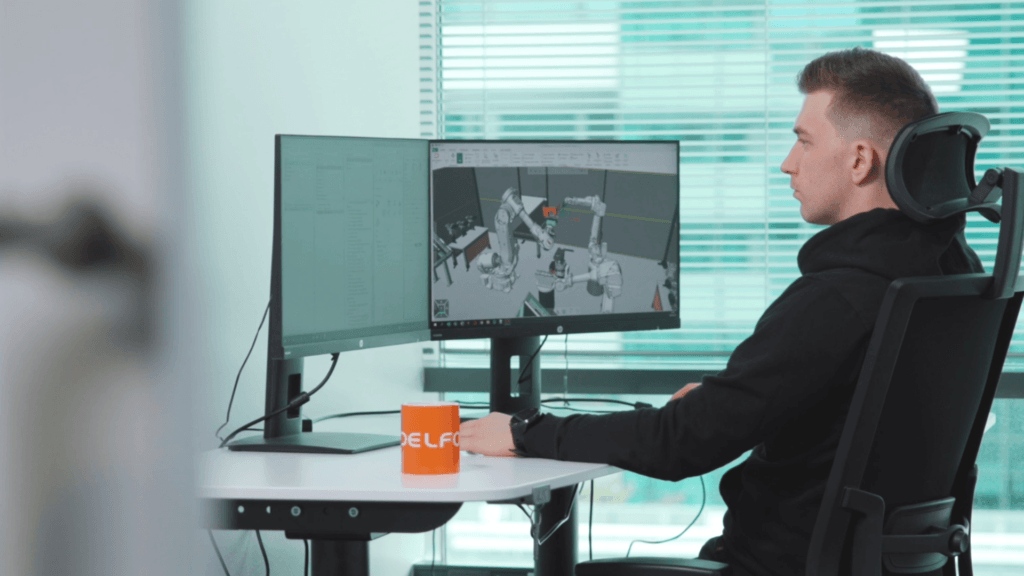

By facilitating early problem identification and resolution, virtual commissioning can help enhance operational efficiency and is essential for modern manufacturing – helping maximize ROI and being a transformative element in developing advanced, efficient, and reliable manufacturing systems all from the comfort of your office (or wherever you may be).

Visual Components offers the necessary tools and expertise for virtual commissioning.

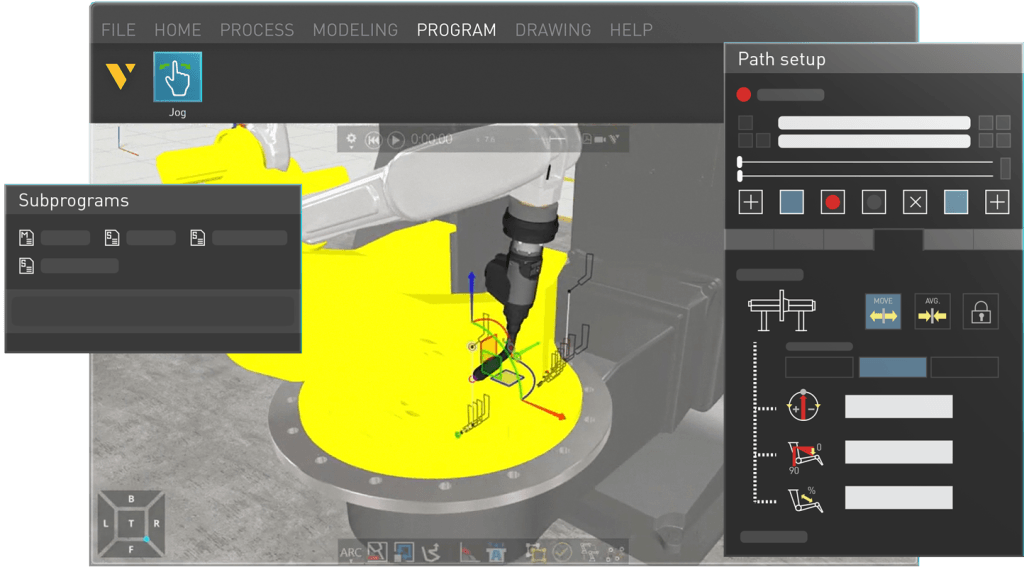

For robot programmers

Optimize robot programs virtually to reduce on-site programming and commissioning effort.

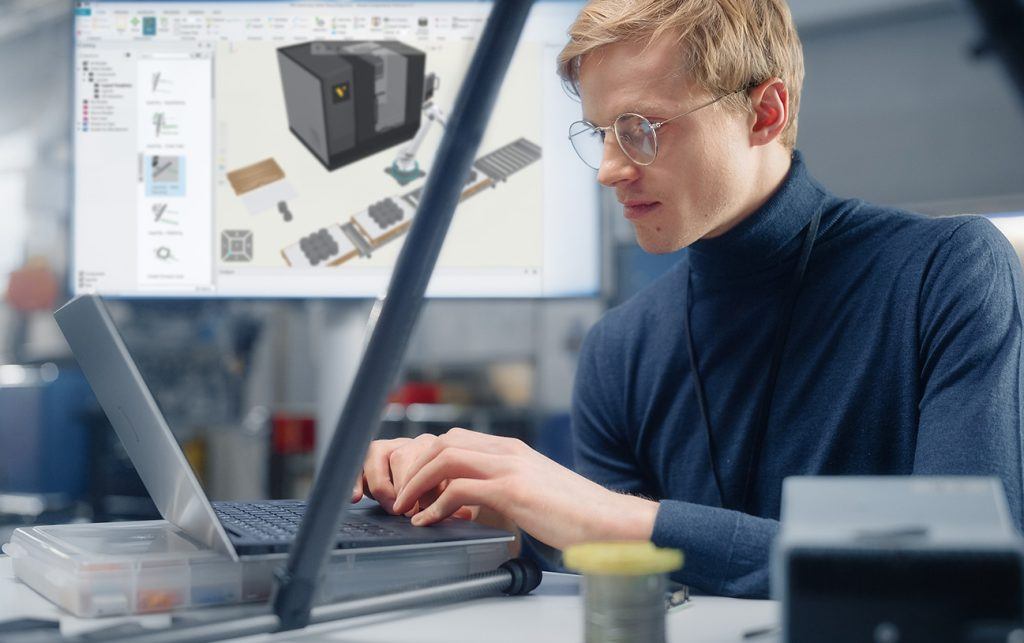

For manufacturing engineers

Quickly design, optimize and adjust layouts with minimal training to test what-if scenarios and minimize risks.

For production managers

Accurately optimize process and mitigate risks to maximize efficiency according to your operational needs.

For system integrators

Improve planning, decision-making and sales processes to boost productivity, reduce errors, enhance collaboration and customer engagement.

How are our customers using Visual Components for virtual commissioning?

Wächter Packautomatik: navigating variations in furniture packaging

Learn how Visual Components helped demonstrate and streamline furniture packaging solutions at high speeds.

Invio Automation: simulating automation in the manufacturing of windows

Learn how Visual Components helped evaluate concepts to increase throughput while maintaining or reducing overall direct labor.

Etteplan: designing turnkey solutions for customers

Learn how Etteplan uses Visual Components manufacturing simulation for business growth by providing turnkey solutions to their customers.

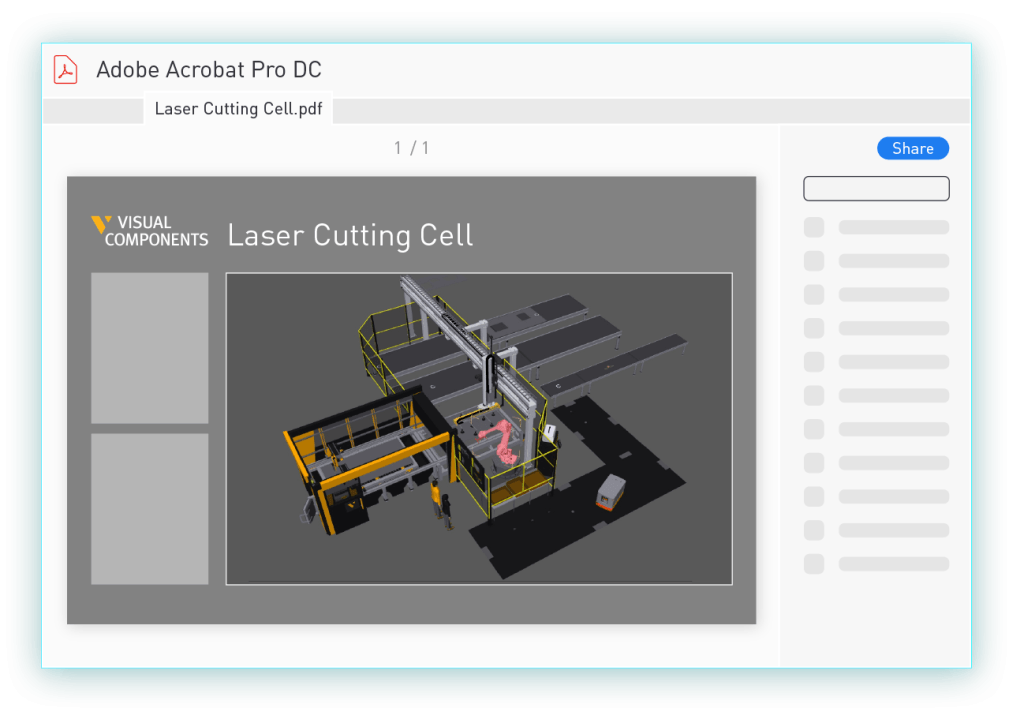

Master virtual commissioning in Visual Components

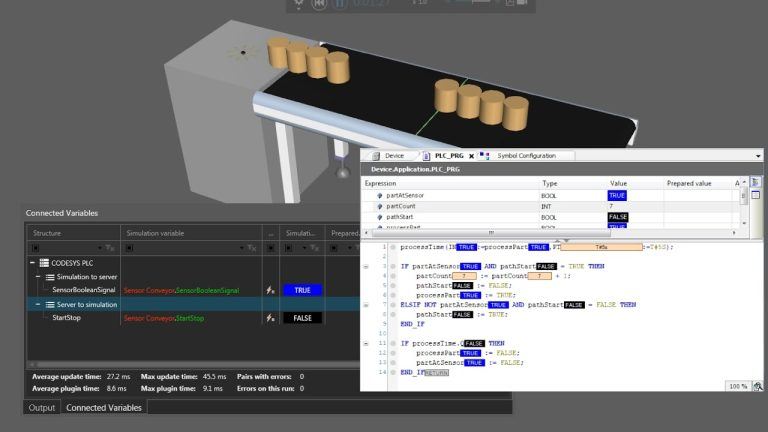

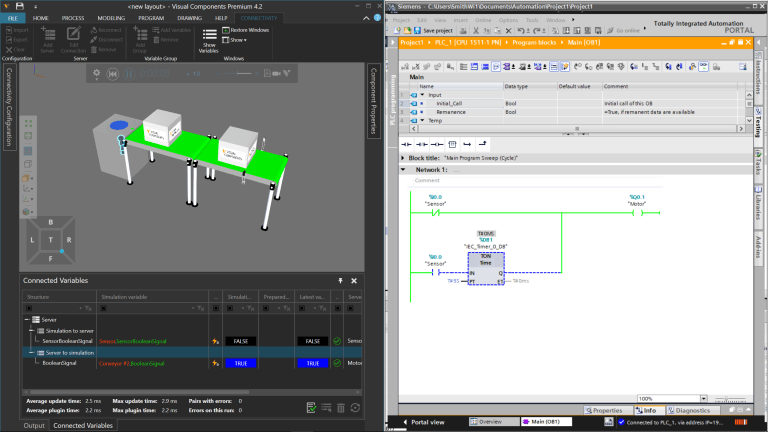

Connect a remote OPC UA server

Learn how to connect a remote OPC UA Server and PLC with a 3D simulation.

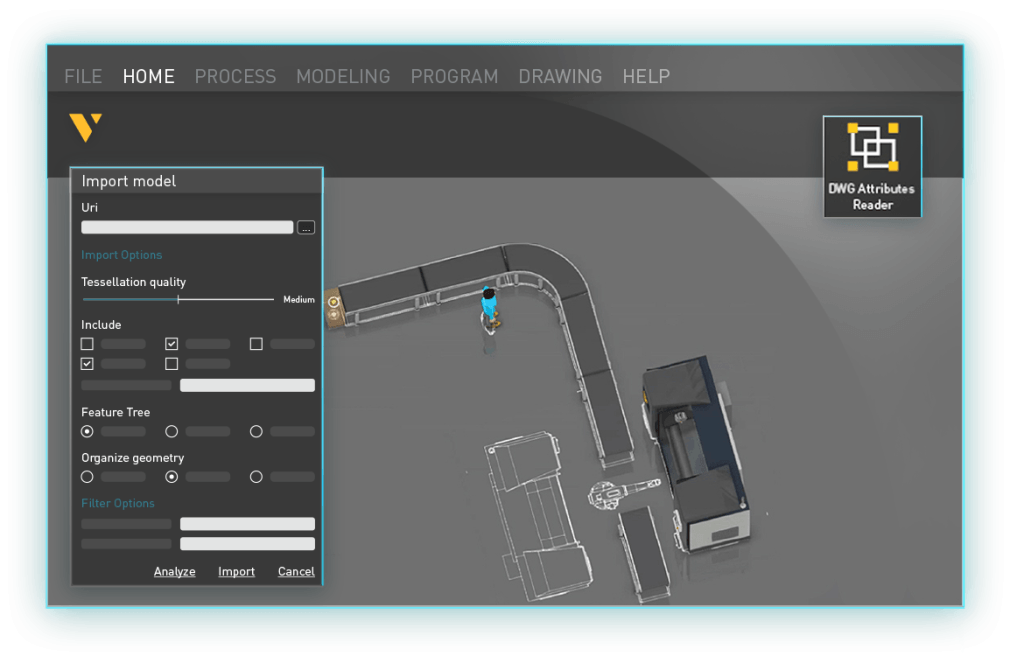

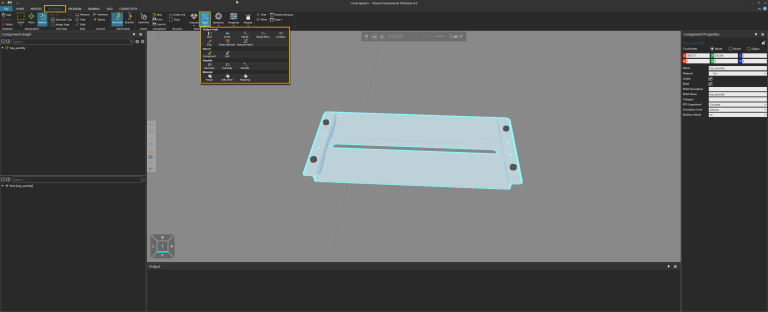

Geometry feature tools for component modeling

Learn how to use geometry feature tools to make the imported CAD models parametric.

Make a simple conveyor PLC ready

Learn how to model a conveyor and test it with sensors and PLCs.