Bring your concepts to reality

with Visual Components

Get started on your digital transformation journey. Discover the future of manufacturing with optimized efficiency.

Try it yourself

Move around and get up close in the 3D space. With Visual Components, you can effortlessly share your simulations with colleagues and clients, making it easier than ever to demonstrate your ideas and projects.

How our customers benefit

Boost your efficiency by 30%

Increase efficiency in your manufacturing operations with our virtual commissioning tools, enabling precise control over process performance through simulation and validation of designs with PLCs and robot controllers.

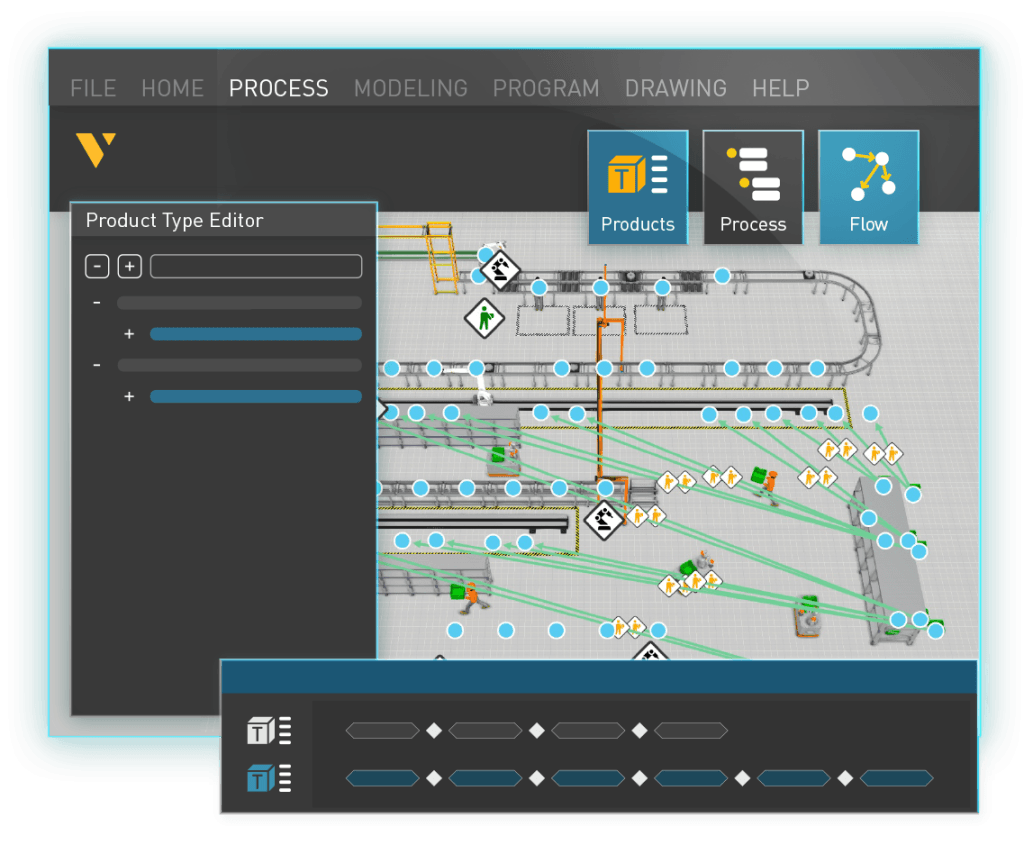

Save costs by 15%

Design many what-if scenarios in hours instead of days, have better insights into your projects, minimize your investment and save additional costs from your projects.

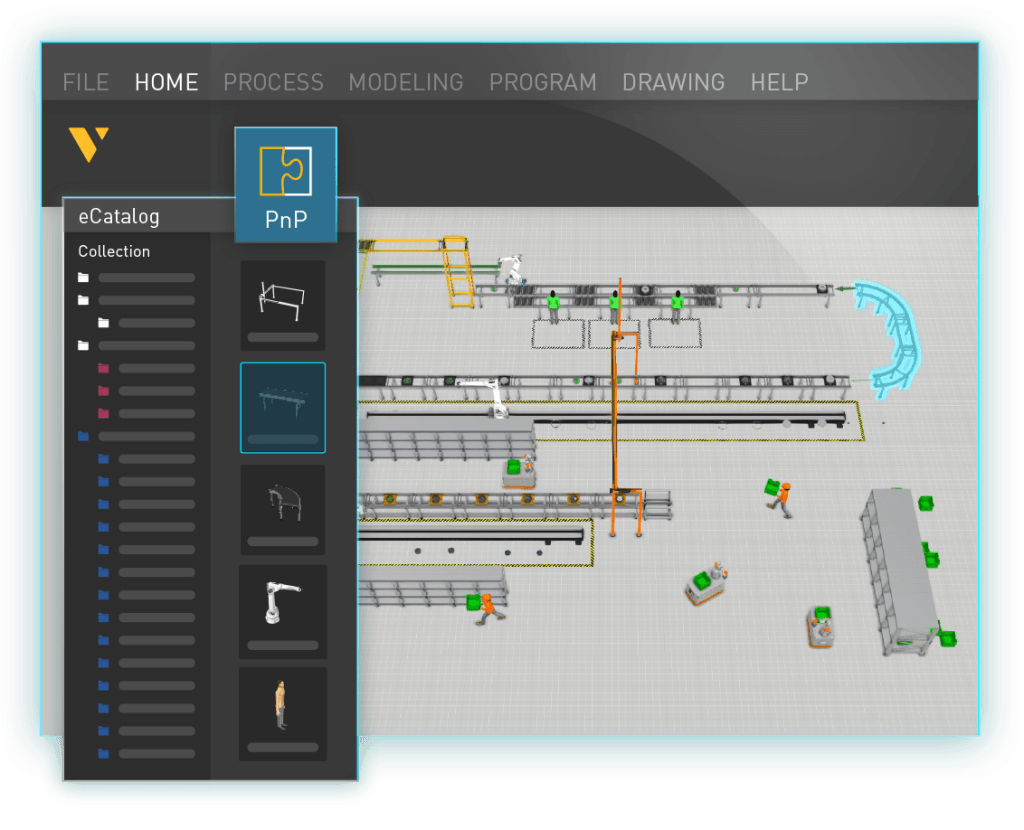

3000+ ready-made CAD components

Use our extensive library of 3D models with more than 1,600 robots, 70+ brands, and a wide range of conveyors, machines, resources, robot tools, factory facilities and more.

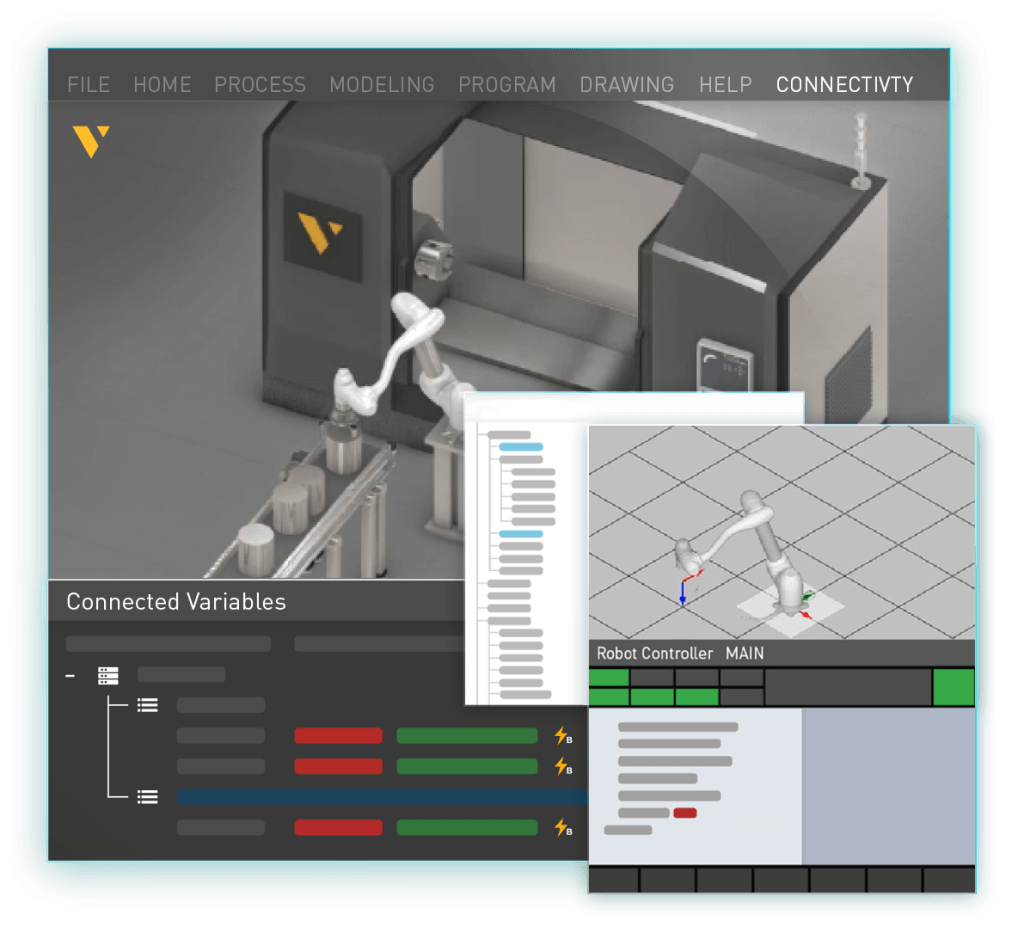

Reduce robot programming time by 80%

Program your robots more quickly and efficiently than with traditional manual programming methods. Test and optimize your programs before downloading them to the physical robots.

Maximize robot utilization by 95%

Optimize your robots’ utilization with fast and easy offline programming for tasks such as welding, material processing, or spray painting and eliminate robot downtime.

Enhance safety

Reduce the risks of accidents and injuries by programming heavy-duty industrial robots through offline programming software. Program from anywhere without any risk of robot collisions or physical accidents.

Trusted by +2400 organizations in the manufacturing industry worldwide to automate their production