Volvo construction equipment invests in smart manufacturing in a new pilot project

Smart manufacturing and robotization are becoming increasingly common in Swedish industries. Volvo Construction Equipment is at the forefront of this development and is now investing in a pilot project that will streamline the production of low volume items and reduce production costs.

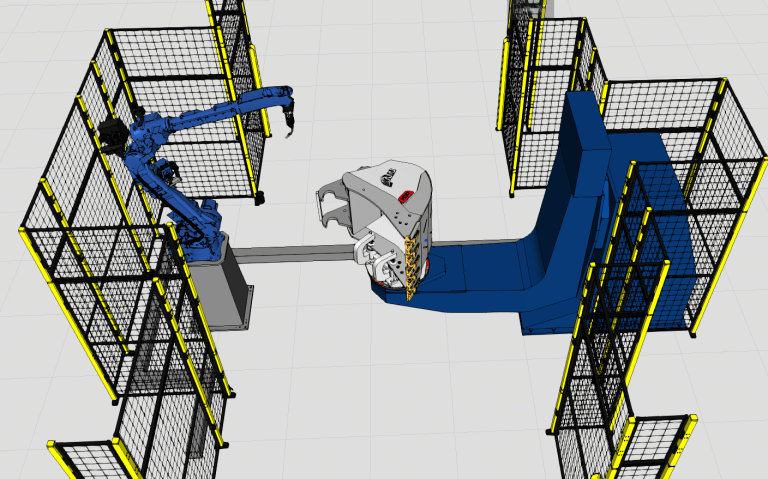

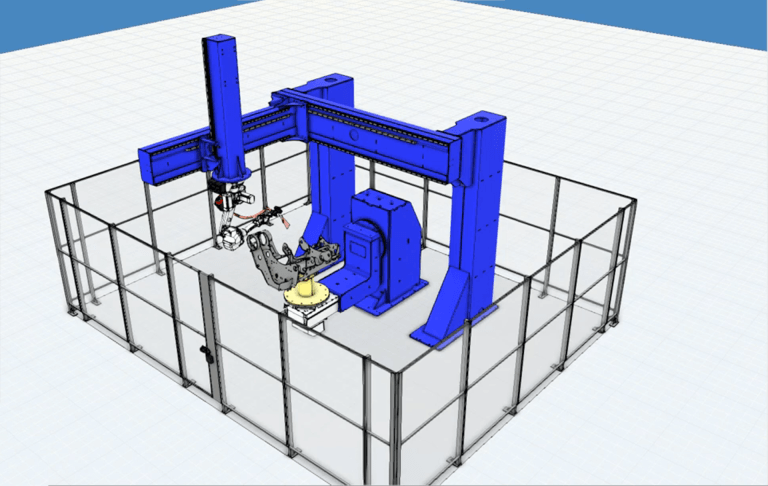

Many manufacturers in the automotive and manufacturing industry have items that are to be produced in low volume, but in several variants. It often requires access to custom machines, jigs, and fixtures that are not used for some time or that take a long time to change, which is cost intensive. Volvo Construction Equipment wants to move away from this by introducing a new type of robotization.

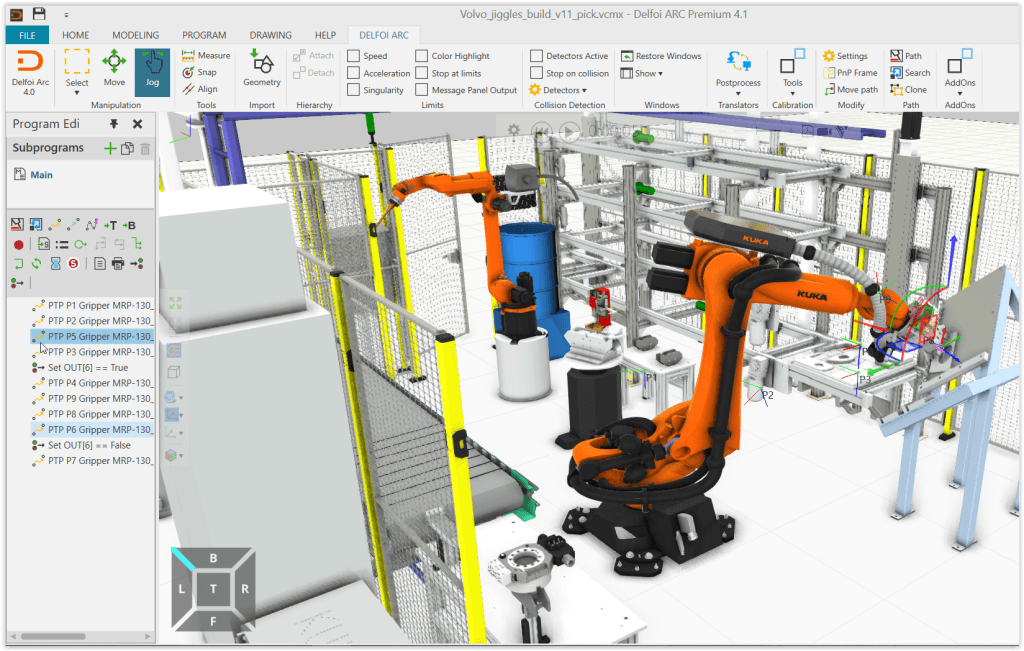

We have developed a solution that is able to use the same equipment for many different items and in the fall we will start production with a pilot project. We will work with a robot cell and use the Delfoi Robotics (now Visual Components Robotics OLP) offline programming system

Erik Åstrand, a specialist in welding optimization at Volvo CE

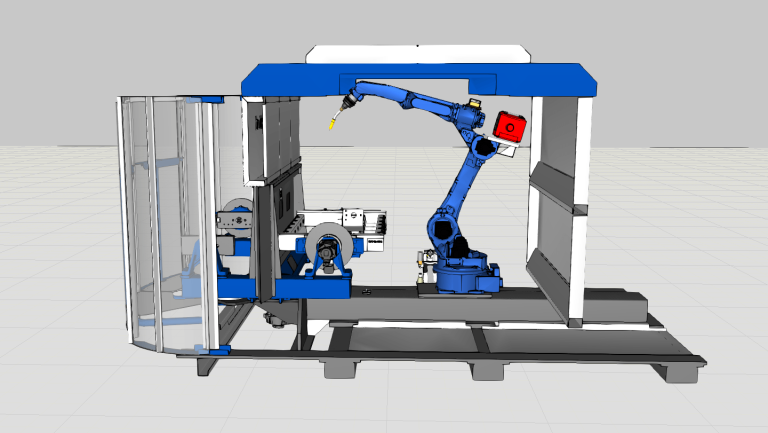

”Jigless” welding

The pilot project will focus on the manufacturing of components for Volvo’s dumpers in Braås. The optimization involves introducing ”jigless” welding in production, i.e. welding is carried out using flexible robots instead of customized jigs or fixtures. Erik mentioned,

In the robot cell, we have a handling robot and a welding robot that build the items together. The handling robot picks up and places the different parts while the welding robot welds them together and then we continue a bit at a time until the item is complete.

Mainly, it is about items up to about 60 kilos, but in the long run, the concept can also be an integral part in the production of major components such as vehicle frames. Maximum manufacturing flexibility also requires the fast creation of programs when the robots weld a new item. There, Delfoi Robotics’ offline programming system plays a key role.

Offline programming

Offline programming means that the robots are programmed in a computer environment without disturbing the process. This reduces the number of production stops and reduces production costs. Delfoi Robotics is the world leader in the field of welding, which made them an obvious choice of supplier. About Delfoi Robotics, Erik concluded,

We wanted the best technical solution and software that is compatible with as many robot brands as possible. Delfoi’s system is very visual and intuitive to program.

The robot cell in Braås will be used for 30 low-volume items in a continuous one-piece flow without any set times. If the pilot project goes well, the plan is to apply the same manufacturing principle to more products and other Volvo CE plants.

Further reading

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...

Combatting the welder shortage: how AMI Attachments enhances production efficiency with Visual Components OLP

AMI Attachments, a leading North American manufacturer of heavy equipment attachments, sought to improve product throughput and meet evolving market demands while navigating a welder shortage. By implementing Visual Components...

Ponsse is driving forest machine innovation and improving productivity with Visual Components Robotics OLP

Ponsse Plc., a global leader in forest machine manufacturing, has transformed its production process by leveraging Visual Components Robotics OLP.