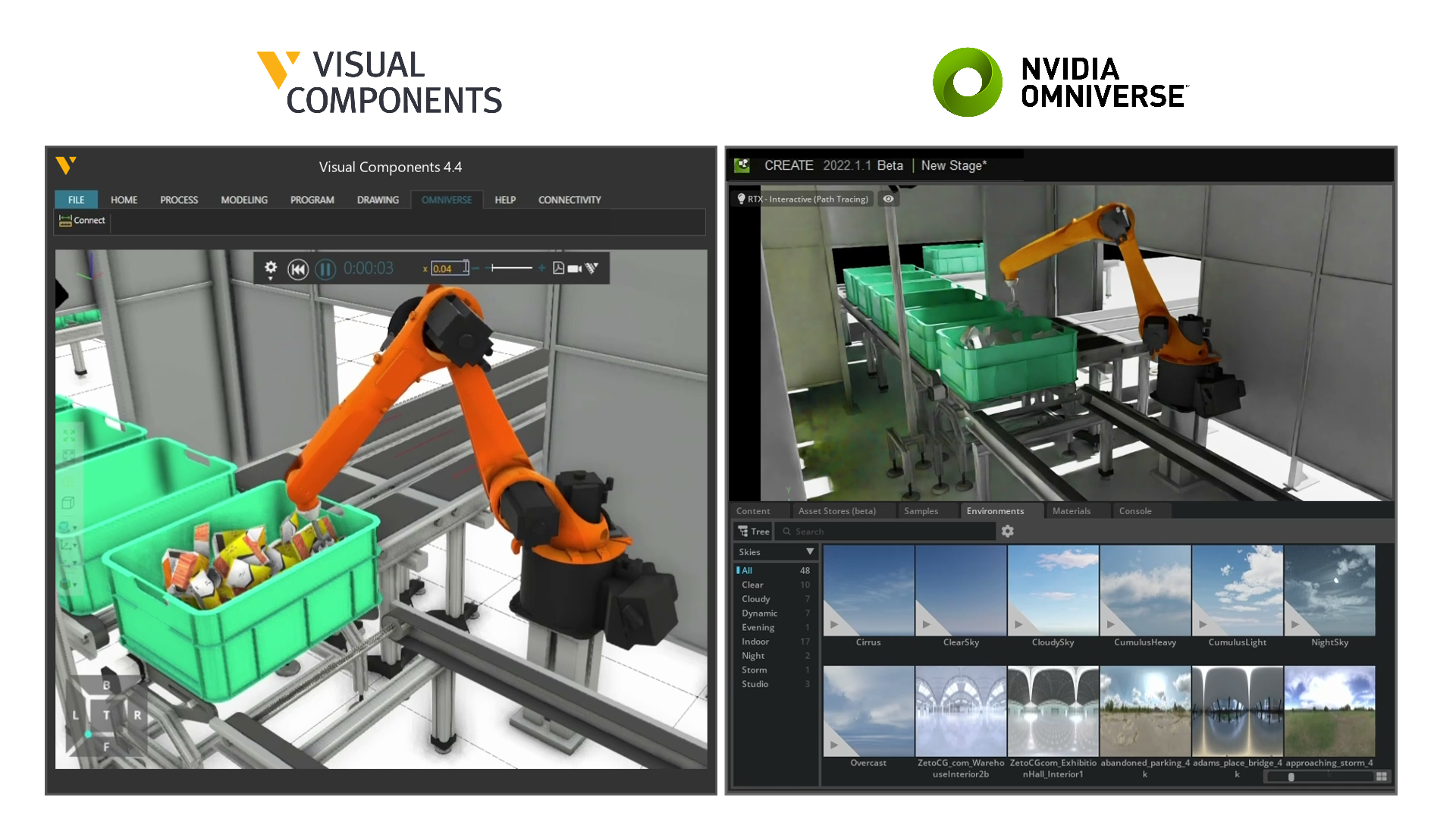

Visual Components connector for NVIDIA Omniverse: a perfect recipe for manufacturing digitalization

The combination of Visual Components manufacturing simulation and NVIDIA’s state-of-the-art computing knowledge results in a powerful solution for the digitalization of the manufacturing industry.

The Visual Components connector for NVIDIA Omniverse™ offers a unique opportunity for the manufacturing industry to truly build a virtual world that emulates their operations and connects these virtual configurations with the real assets to create the digital twins.

Opening new opportunities

The combination of Visual Components and Omniverse results in a powerful toolkit as it merges the best of Visual Components manufacturing simulation features and NVIDIA’s state-of-the-art computing knowledge to create physically accurate virtual worlds.

The real value of this connector, however, is that it opens a gateway to a range of applications either developed by NVIDIA or other vendor-specific solutions for countless possibilities and use cases, some of which are known but many yet to be explored.

One of our clients, a Taiwanese green electronics company is using the combination of Visual Components, Omniverse, and Isaac Sim. NVIDIA Isaac Sim, powered by Omniverse, is a scalable robotics simulation application and synthetic data generation tool to develop, test, and manage AI-based robots.

For this case, this client uses Visual Components to quickly set up the robot cell with simple plug-and-play features and hundreds of ready to simulate 3D models. One of the robots in this cell has a camera that’s used to check if certain parts are correctly positioned and inserted according to the requirements.

The client programs their robots with Visual Components powerful OLP features and simulates the programs to ensure the accuracy and cycle times. Once the robot programs are verified, they use the Visual Components connector to sync the design with NVIDIA Omniverse Nucleus asset server which is connected to Isaac Sim.

The client is teaching the AI to recognize the correct actions first before executing the robot program through NVIDIA Isaac Sim. Additionally, this project also helps in virtual yet realistic training before any real deployment saving time and costs from the project schedule. This is just one of the use cases of how the customers can benefit from Visual Components and NVIDIA Omniverse connection.

Updates and practicalities

It is important to remember that NVIDIA Omniverse capabilities are available to Premium users with the latest version of Visual Components.

The initial version of the Visual Components connector for NVIDIA Omniverse launched in the first week of May 2022. After the initial launch, several projects have kicked off with selected leading players in the manufacturing and industrial automation business. Each of these projects carries a different purpose and goal of using Visual Components manufacturing simulation with NVIDIA Omniverse. However, if you or your company has a specific use case that you’d like to address by using Visual Components and NVIDIA Omniverse, reach out to us using this contact form.

Further reading

Visual Components partners with CADENAS to deliver millions of vendor-verified CAD models for 3D manufacturing simulation

Seamless access to verified CAD models At Visual Components, we strive to improve how our users plan, simulate,...

Introducing Visual Components 4.10 – Design beyond limits

Design beyond limits. That’s the promise of Visual Components 4.10. As manufacturing and robotics evolve, we continue to prioritize usability, ensuring that our tools not only keep up with industry...

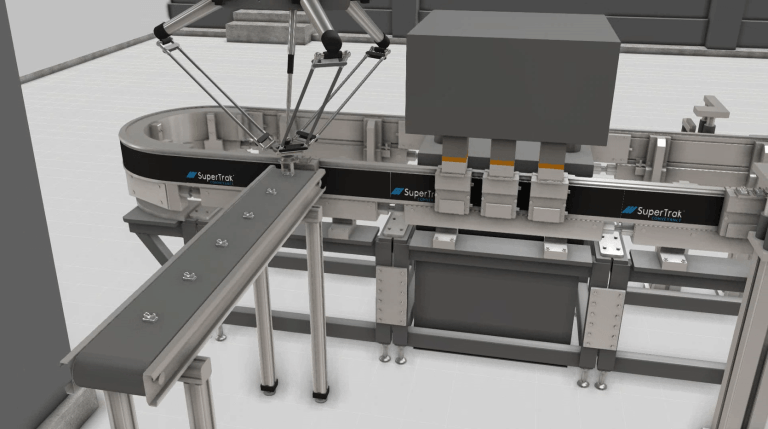

SuperTrak CONVEYANCE now in the Visual Components eCatalog

Visual Components’ eCatalog now features components from SuperTrak CONVEYANCE! SuperTrak CONVEYANCE™ is a magnetic conveyance platform that revolutionizes...