Introducing Visual Components Robotics OLP

We’re excited to announce a significant upgrade for Visual Components. We’ve transitioned to a robust solution that serves both manufacturing simulation and robot offline programming. This new offering, named ‘Visual Components Robotics OLP’, is built on the industry-leading Delfoi Robotics OLP technology. Now, our offerings are unified under a single product and brand.

Discover the next generation of offline robot programming software

Rooted in manufacturing simulation since 1999, the story of Visual Components epitomizes innovation and ambition. With three decades in the sector, we’ve gained insights into the major challenges and shifts in manufacturing.

Last year in October, Visual Components acquired Delfoi Robotics – the Finnish company developing industry-leading offline robot programming (OLP) solutions for the manufacturing industry. Since then, we have worked towards combining Visual Components’ powerful manufacturing simulation solutions with that of Delfoi Robotics OLP software to provide a seamless customer experience.

This strategic acquisition allowed Visual Components to begin our journey of widening our product portfolio and offering one solution for all with advanced features for manufacturing planning and robot programming. Together, these technologies will help the manufacturing industry to increase productivity, minimize production downtime, and reduce engineering time, costly mistakes, and waste – making digital production transformation possible.

Today, we are happy to announce that Visual Components has successfully transitioned to a new, more powerful solution for both manufacturing simulation and robot offline programming customers. With the introduction of Visual Components Robotics OLP – based on the Delfoi Robotics OLP technology – we bring both offerings under one unified product portfolio and brand.

Put simply, Visual Components Robotics OLP makes digital production transformation possible. It’s more than just a product release; it’s a testament to our understanding of industry challenges and continued commitment to addressing them head-on. We’re bridging the efficiency gaps and streamlining processes to ensure our customers always stay one step ahead.

Mikko Urho, CEO of Visual Components

Addressing the current manufacturing landscape

The welding industry is facing an unprecedented challenge. According to the American Welding Society (AWS), the USA alone is on the brink of a 400,000 welder shortage by 2024. This trend is not isolated from welding; many skilled trades are sounding similar alarms.

As industries grow and evolve, there’s a pressing need for innovative solutions to address these workforce gaps. One might assume that the rising adoption of industrial robotics could offer a reprieve. However, despite their increasing presence in manufacturing, these robots are often underutilized – it’s not uncommon to have a utilization rate under 50%. Their full potential is often hindered by the time-intensive and laborious manual programming required with teach pendants, as well as the need to quickly changeover processes from one to another. The industry also faces the task of navigating an ever-increasing mix of technologies, which, while promising innovation, requires knowledge in integrating and managing these systems. Lastly, the difficulties in product mix and the associated ramp-up times further test manufacturers’ ability to quickly adapt to changes in the market.

The solution: Visual Components Robotics OLP

Given this backdrop, our latest OLP offering with Visual Components Robotics OLP emerges as a solution, offering a response to these challenges, promising to optimize robot utilization, decrease the mix of technology, and enhance overall production quality and efficiency, on a single platform: all for one, one for all.

With that said, our latest solution aims not to eliminate jobs, but rather to help fill in the gaps caused by these shortages in the workforce.

In times of labor shortages, it (VC Robotics OLP) is going to be something that allows a company to continue to operate efficiently, even when they can’t find the people. This software ensures that the workflow doesn’t break down and that tasks are carried out consistently.

Scott Walter, Founder and Chief Technology Advisor at Visual Components

Our solution is tailored to accommodate most industrial processes and robotic layouts, ensuring compatibility and flexibility where users can expect reliable, accurate, and 10x faster programming efficiency. Furthermore, it boasts compatibility with main industrial robot and cobot brands, both new and old, including 17 post-processors from the likes of KUKA, ABB, YASKAWA, FANUC, just to name a few, allowing users to seamlessly transfer their robot programs from VC Robotics OLP to physical robots on the shop floor.

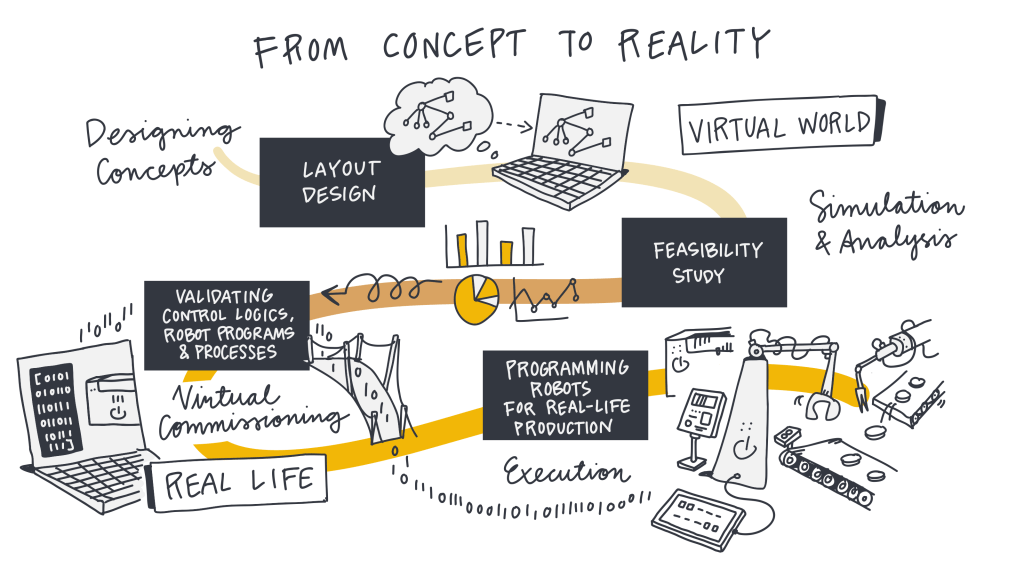

Conclusion: from concept to reality

The introduction of Visual Components Robotics OLP is more than just a product release—it’s a testament to our understanding of industry challenges and our continued commitment to addressing them head-on, and allowing our customers to bring their manufacturing concepts to reality.

The world of manufacturing is dynamic, and to stay ahead, embracing tools like OLP is essential. Through the VC Robotics OLP, we’re bridging the efficiency gaps and streamlining processes to ensure our customers are always a step ahead and enabling their digital transformation.

Dive into what our latest offering can do for you by checking out the Visual Components Robotics OLP product page. Let’s make our manufacturing processes smarter and our robots more productive, together.

Further reading

Visual Components partners with CADENAS to deliver millions of vendor-verified CAD models for 3D manufacturing simulation

Seamless access to verified CAD models At Visual Components, we strive to improve how our users plan, simulate,...

Introducing Visual Components 4.10 – Design beyond limits

Design beyond limits. That’s the promise of Visual Components 4.10. As manufacturing and robotics evolve, we continue to prioritize usability, ensuring that our tools not only keep up with industry...

SuperTrak CONVEYANCE now in the Visual Components eCatalog

Visual Components’ eCatalog now features components from SuperTrak CONVEYANCE! SuperTrak CONVEYANCE™ is a magnetic conveyance platform that revolutionizes...