Introducing Visual Components 4.9 – Craft with clarity

The latest version of our manufacturing simulation and robot offline programming solution is here, bringing improved clarity to production planning and optimization in manufacturing. With greater clarity, our users can expect to get more done, more easily, and with better understanding, especially when dealing with larger manufacturing and system integration projects.

What’s new

Sub-layouts have been introduced, allowing users to effortlessly navigate, manage, and collaborate on factory layout designs. This new layout system enables the segmentation of large layouts into more manageable sections or “sub-layouts,” making the design process more flexible and layout organization more intuitive.

Continuing our commitment to broaden robot connectivity on our platform, Visual Components 4.9 includes new connectivity plugins for Kawasaki and Yaskawa robots, accelerating the testing and validation of robot programs. This integration simplifies the transition from simulation to real-world application, ensuring that your Yaskawa and Kawasaki robotic systems are up and running quickly and correctly.

Visual Components 4.9 also brings with it new and redesigned offline robot programming (OLP) calibration tools. These new tools are more intuitive and offer guided instructions with detailed reporting for robot calibration, enabling an accurate match between the virtual and physical worlds.

To support a broader range of robotic applications, Visual Components 4.9 simplifies the programming of robotic assembly operations. Users can now easily build, optimize, verify, and validate assembly operations, making the programming process significantly faster.

Learn more about what’s new by watching the video and reading the details below.

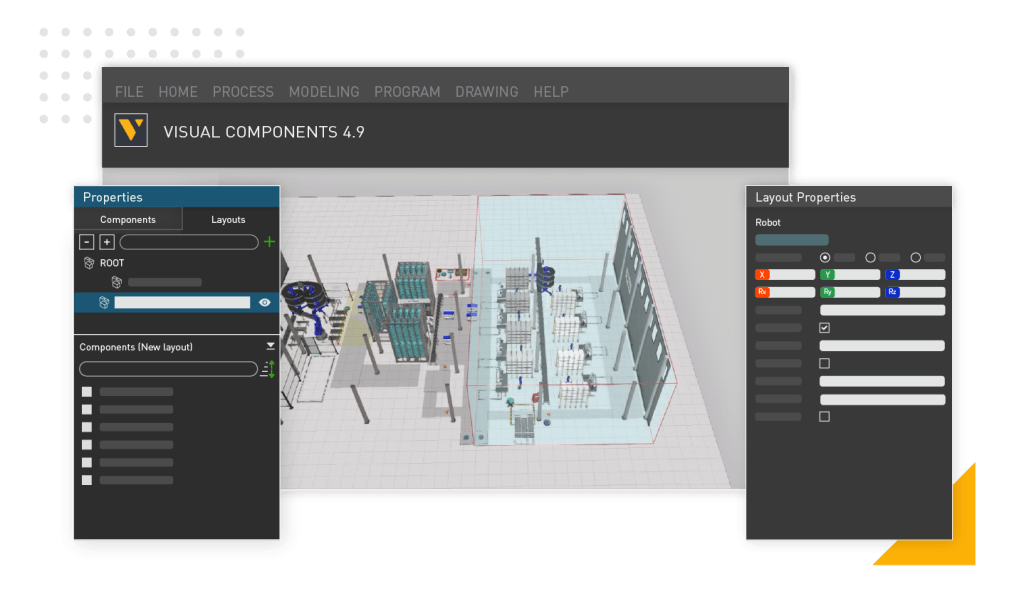

Design, organize, and collaborate with sub-layouts

Imagine a large and complex factory layout organized into neat, manageable sections. That is the promise of sub-layouts in Visual Components 4.9. This new feature allows you to break down larger layouts into smaller “sub-layouts” for focused design and modification efforts. It provides much-needed structure, especially for projects with multiple stakeholders, enabling efficient navigation and responsibility management.

Sub-layouts make the design process clearer and tidier, transforming messy setups into organized units. You can group components based on type, brand, or any other category and arrange them in a structured order. This not only simplifies layout management but also helps maintain privacy by allowing you to easily hide certain areas or components when sharing your designs.

Creating sub-layouts is possible in all Visual Components products.

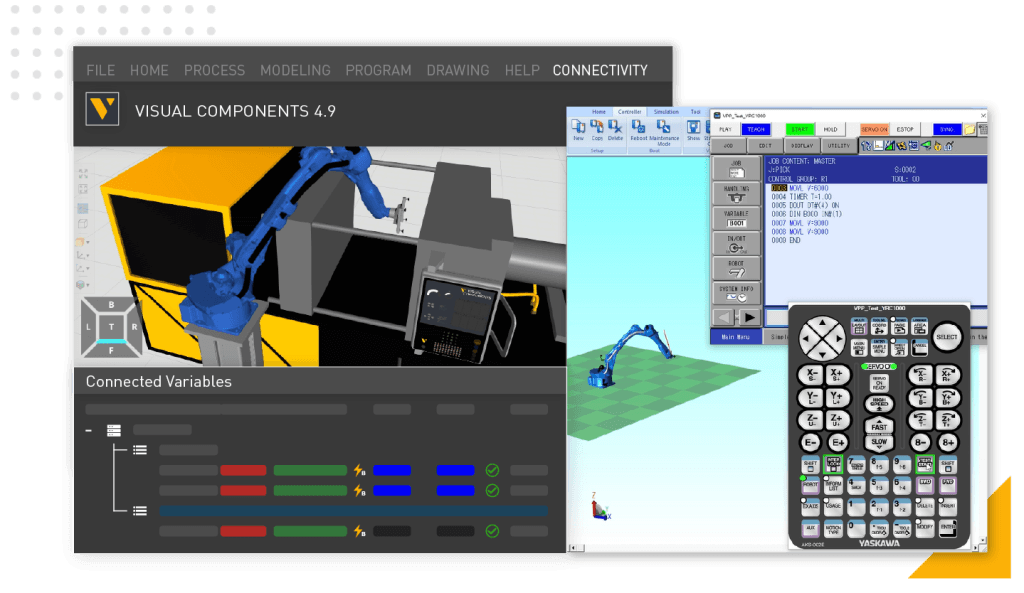

Connect to Yaskawa and Kawasaki robots

Visual Components 4.9 continues to bridge the gap between virtual simulation and physical robotics with the addition of new Kawasaki and Yaskawa connectivity plugins, simplifying the process of importing, simulating, and executing robot programs to closely mimic real-world scenarios with accurate cycle times and movements.

By integrating the proprietary robot software of Kawasaki (K-Roset) and Yaskawa (MotoSim) robots with advanced simulation features, Visual Components 4.9 offers a reliable, time-saving solution for robotic programming and execution. It ensures systems are thoroughly optimized and issues are resolved well before any physical implementation. As a result, the transition from virtual to real becomes more efficient and error-free. You can simulate your plans, test robot programs alongside PLCs, and validate everything in a single environment, eliminating the need for multiple tools – continuing our promise to be the all-in-one tool for all your virtual commissioning needs.

With the additions of Kawasaki and Yaskawa, Visual Components now offers connectivity plugins for an even broader range of robotics industry leaders, including ABB, Doosan, Fanuc, and KUKA robots.

Connectivity to Kawasaki and Yaskawa robots (along with their post-processors) is available in Visual Components Premium and Premium OLP 4.9.

More intuitive robot calibration

The redesigned OLP calibration tools in Visual Components 4.9 are tailored to address a crucial aspect of robotic programming in a simulation environment—the need for precise alignment between virtual models and their real-world counterparts. Our latest release enhances the user’s ability to control the calibration process through intuitive, user-friendly interfaces. The guided instructions and detailed reporting help reduce the likelihood of errors and streamline the entire calibration workflow.

These redesigned tools with new robot-to-robot and robot world frame calibration tools are designed to ensure that each programmed motion accurately reflects your intended actions in the real-life robot cell, thereby minimizing the time spent on troubleshooting on-site.

New and redesigned calibration tools are available in Visual Components OLP 4.9 products. Robotics OLP includes new robot world frame calibration while Professional OLP and Premium OLP extend to also include new robot-to-robot calibration.

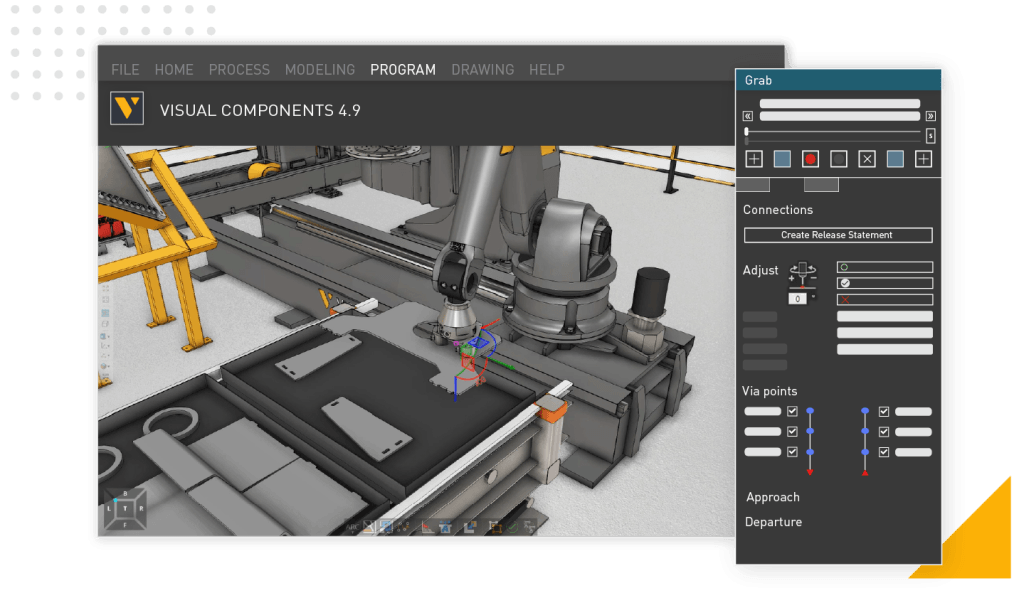

Faster and easier robotic assembly operations

Robotic assembly operations in Visual Components 4.9 have been improved, leading to a process that is more intuitive and less time-consuming.

The new setup tools including automated robot path generation and optimization facilitate a smoother configuration of assembly tasks. They support the verification and validation of assembly sequences within a virtual environment – including the handling of parts, tools, and fixtures – ensuring that every planned robotic action is viable and optimized for real-world application. The result is a powerful and versatile software capable of supporting a wide array of robotic assembly operations that include different applications like welding, gluing, screwing, and many more.

Streamlined robotic assembly operations are available in Visual Components OLP 4.9 products.

Bringing clarity into manufacturing planning

Visual Components 4.9 is designed to help users navigate the complexities of modern manufacturing. Through improved layout management, expanded robot connectivity, redesigned robot calibration tools, and streamlined robotic assembly operations, every feature enhances the user’s ability to craft with clarity.

To fully grasp the potential of Visual Components 4.9 and its new features, check out our Release Notes. Should you wish to discover how this update can help with your operations, our team is ready to demonstrate the full capabilities of our software. Contact us today!

Further reading

Visual Components partners with CADENAS to deliver millions of vendor-verified CAD models for 3D manufacturing simulation

Seamless access to verified CAD models At Visual Components, we strive to improve how our users plan, simulate,...

Introducing Visual Components 4.10 – Design beyond limits

Design beyond limits. That’s the promise of Visual Components 4.10. As manufacturing and robotics evolve, we continue to prioritize usability, ensuring that our tools not only keep up with industry...

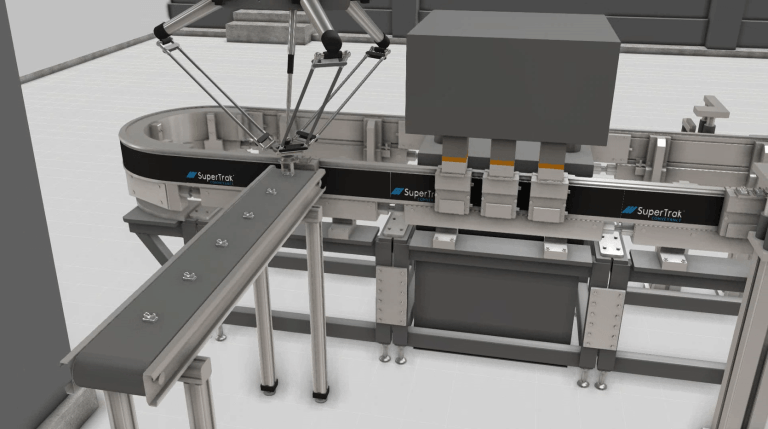

SuperTrak CONVEYANCE now in the Visual Components eCatalog

Visual Components’ eCatalog now features components from SuperTrak CONVEYANCE! SuperTrak CONVEYANCE™ is a magnetic conveyance platform that revolutionizes...