7 reasons simulation software can help you with manufacturing planning

In this post, we take a closer look at 3D manufacturing simulation software, a tool to help you manage the unpredictable nature of manufacturing planning.

We know the challenges manufacturing engineers face on a daily basis. Putting out fires, controlling stock overload and managing performance are some of those challenges. Another big one is responding to the regular irregularities in their production areas. Gathering data, doing the analysis, developing fixes, and convincing management they have everything under control.

There are many tools that manufacturing engineers have at their disposal to manage the unpredictable nature of manufacturing planning. In this post, we take a closer look at one in particular: 3D manufacturing simulation software.

Here are 7 ways that 3D manufacturing simulation software can help you with manufacturing planning:

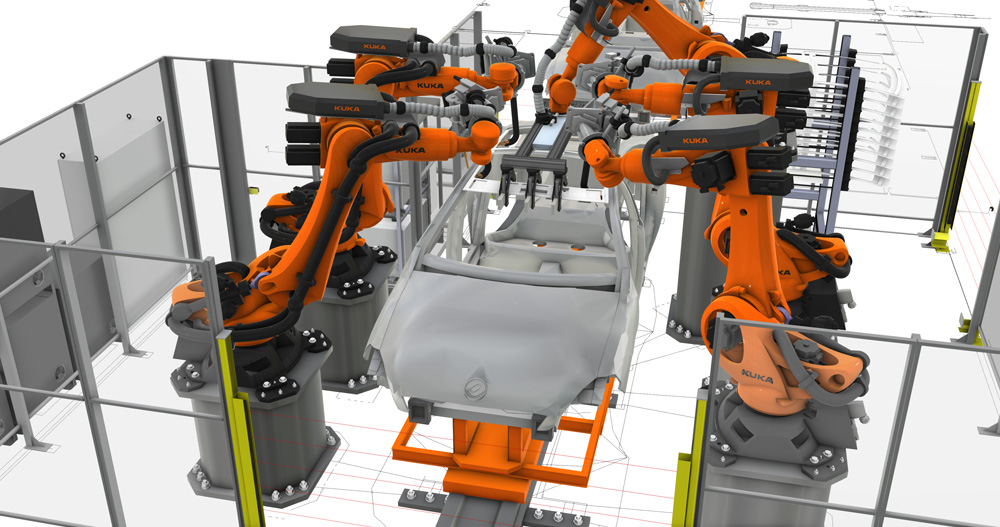

#1. Test changes on your production line in the virtual world first. Testing and simulating the performance of your line in a stress-free virtual world can help you spot issues and improvements before implementing them in the real world.

#2. Troubleshoot early in the process. Did you have a bottleneck shift further upstream? Simulation can help you identify and visualize the problems that are preventing your line from performing.

#3. Simulate the production of your existing line and optimize it. Identify small changes that could lead to big performance improvements by testing and simulating process changes.

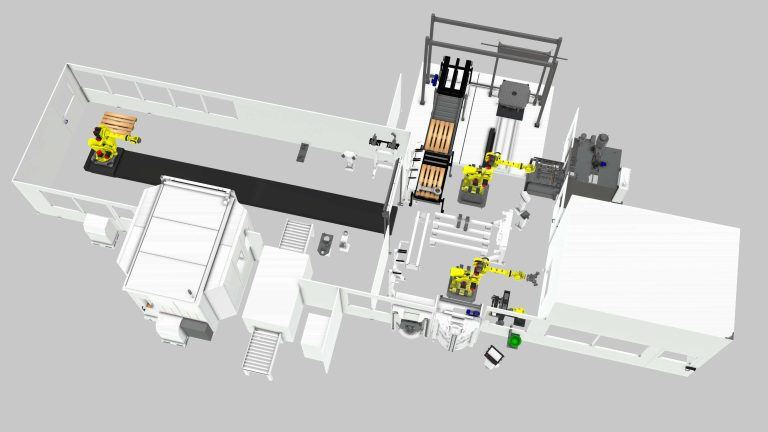

#4. Test different scenarios. What if one of the line workers calls in sick? Or, a machine undergoes extended maintenance? How do each of these scenarios affect production? Simulation allows you to have more insight into your production and can guide you on how to react to different scenarios.

#5. Test product mix variations. When you’re deciding whether to alter the product mix that is being manufactured in your line and want to evaluate the effects this change will have on overall production, simulation can help. You can test product mix variations and see how it affects performance.

#6. Better predictability. A critical point for manufacturers is the just-in-time delivery of their products. 3D manufacturing simulation software can provide you with more predictability of your line operations, and help you plan more realistic delivery schedules.

#7. Communicate your recommendations to management. If you struggle to communicate what is going on in production or to justify any changes to management, you can use simulation to back up your arguments and help them understand better the ROI and benefits of each decision over the line.

While 3D manufacturing simulation software can’t solve all your problems, it can help you make your job a little easier. In our next post, we’ll show you how you can use Visual Components to sell your recommendations and ideas to colleagues and stakeholders.

Further reading

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...

An introduction to virtual commissioning

Virtual commissioning is reshaping the manufacturing landscape by employing computer simulations for testing and optimizing production systems before they're physically built. This approach not only simplifies the setup process and...

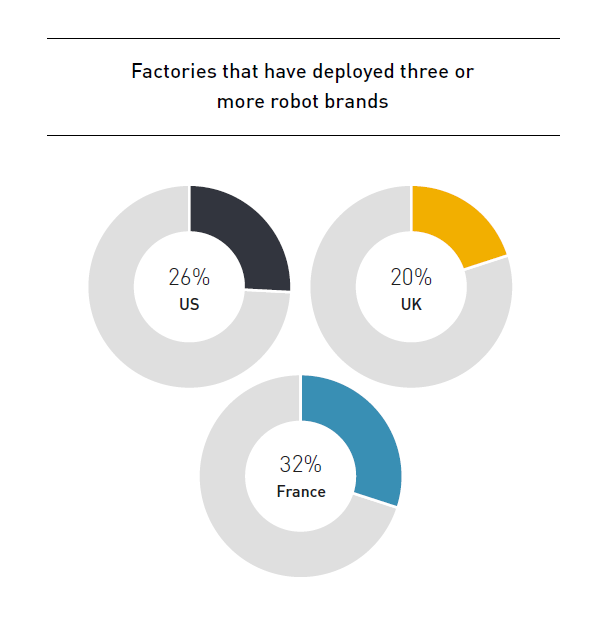

Are manufacturers really ready for the digital era? (survey results)

Legacy equipment and outdated practices can seem like relics from another age, especially as the world zooms ahead with digital innovations. Yet, they're more prevalent in the manufacturing sector than...