Products

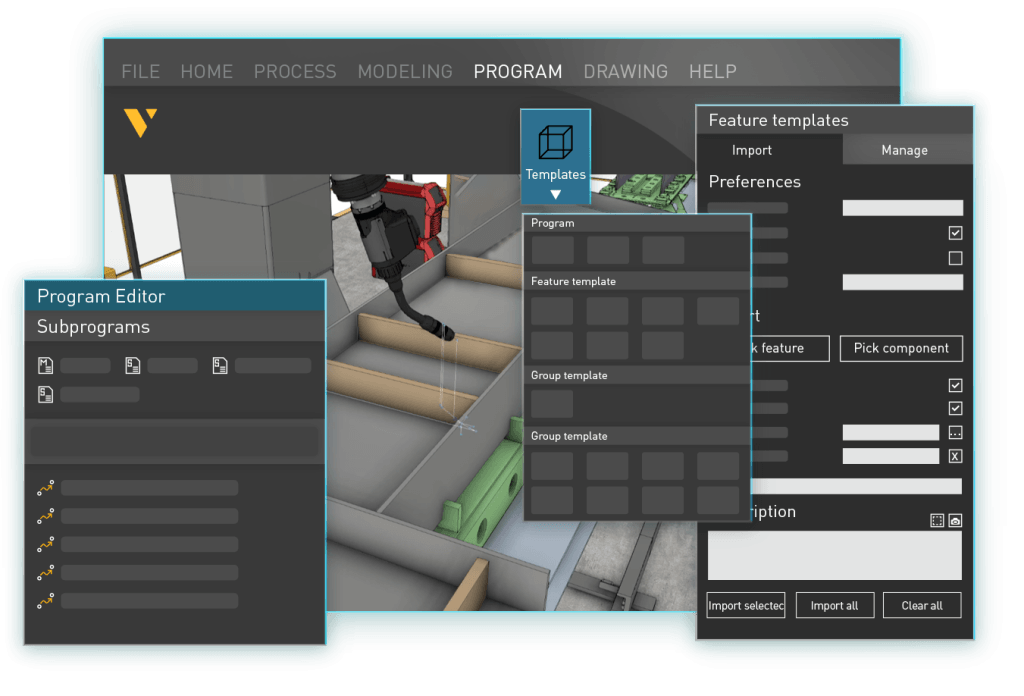

Robot offline programming

The fastest and easiest robot offline programming (OLP) software. Compatible with major industrial robot brands, processes and complexities, helping you maximize quality, robot utilization rate and production output.

Best-in-class offline programming software

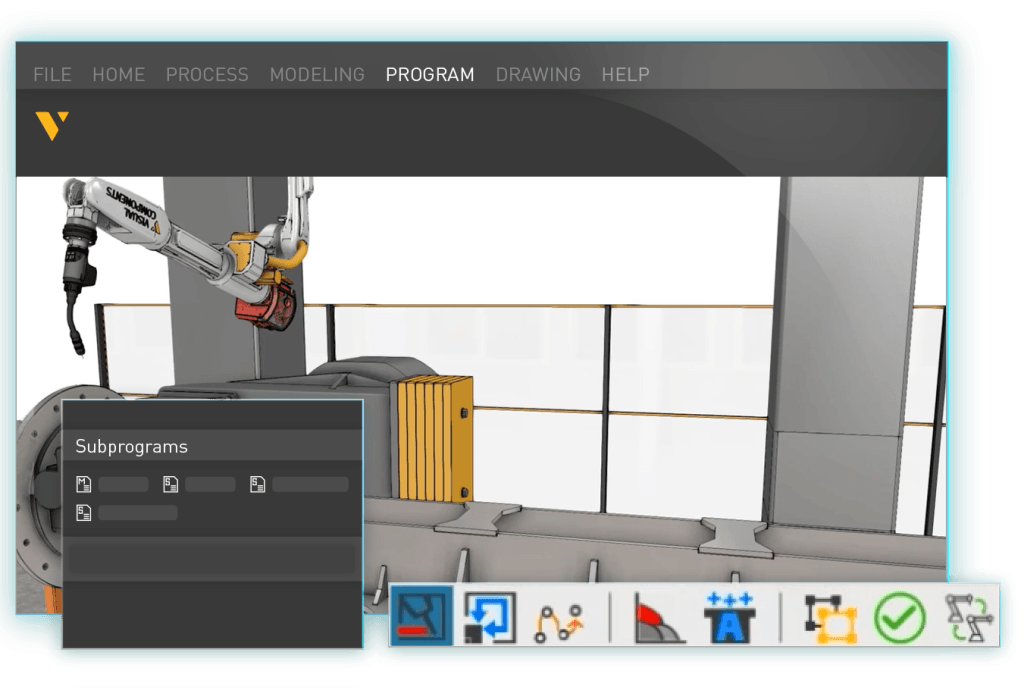

Fastest and easiest

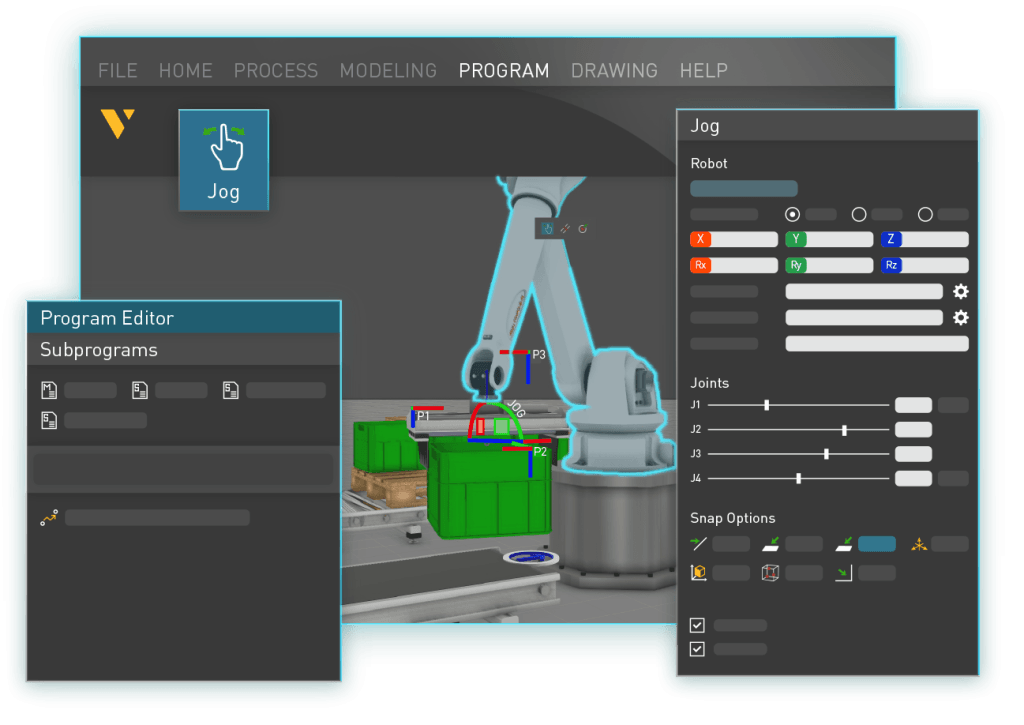

10x faster programming without stopping production. No coding skills required.

Flexible and versatile

One software to maximize robot system utilization, supporting major brands, processes and complexities.

Repeatable quality

Accurate and error-free programs ready for reuse anytime in your process knowledge database.

30 years of experience

Turnkey solutions with a proven track record and decades of successful customer relationships.

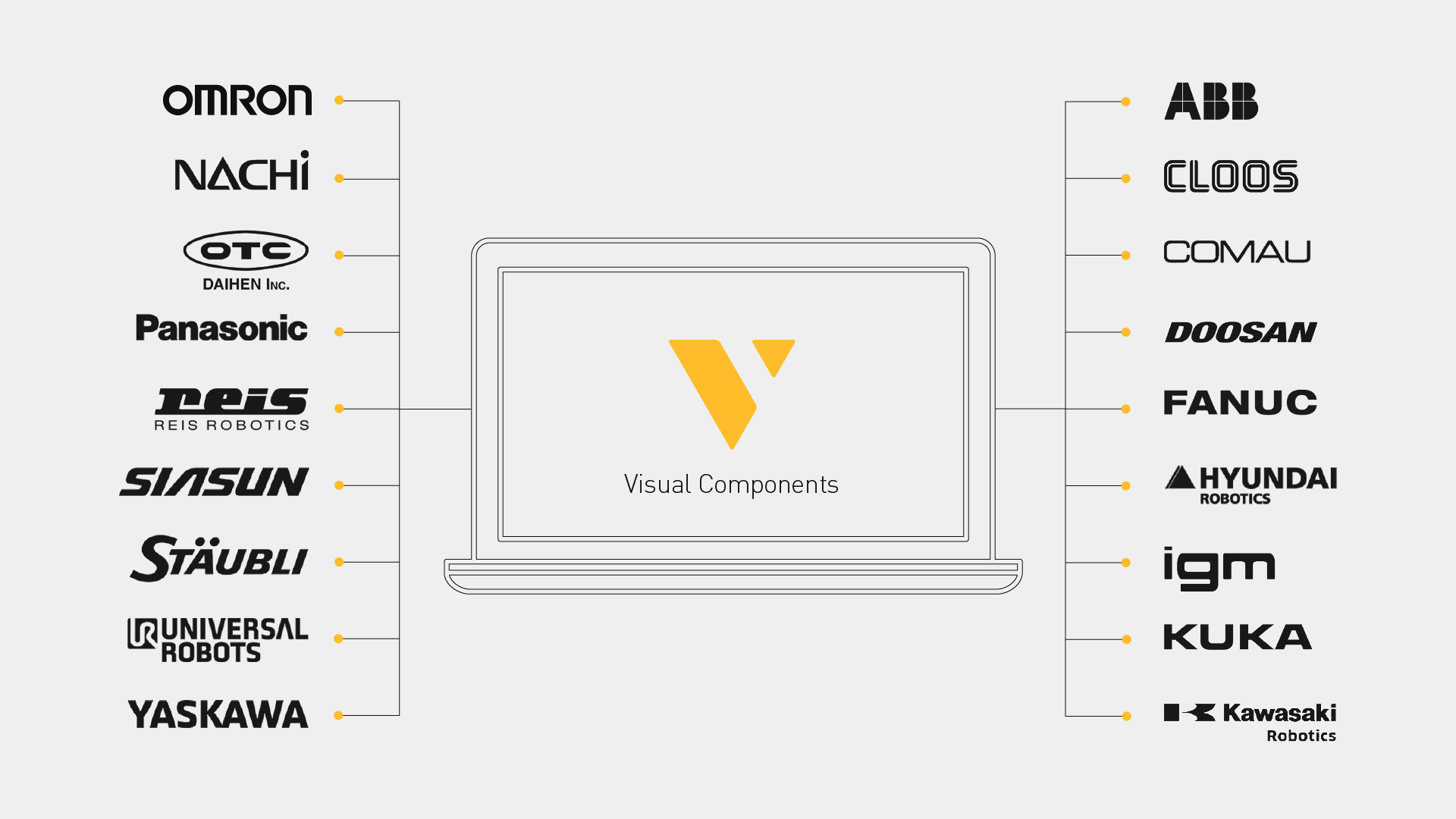

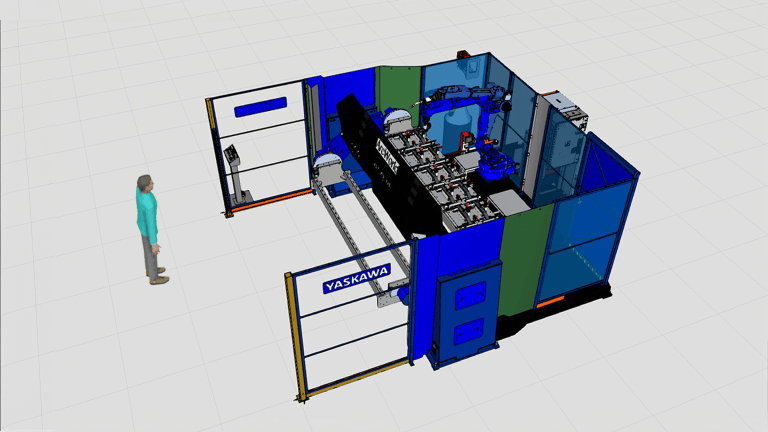

Universal compatibility with any robot system

Robot programming software should enhance production flexibility and adaptability, not limit it due to unique languages. It should be compatible with any robot brand, process or complexity to improve robot utilization and output.

Eliminate the need to use multiple software or know multiple robot programming languages with our 18 post-processors and 40+ robot controllers.

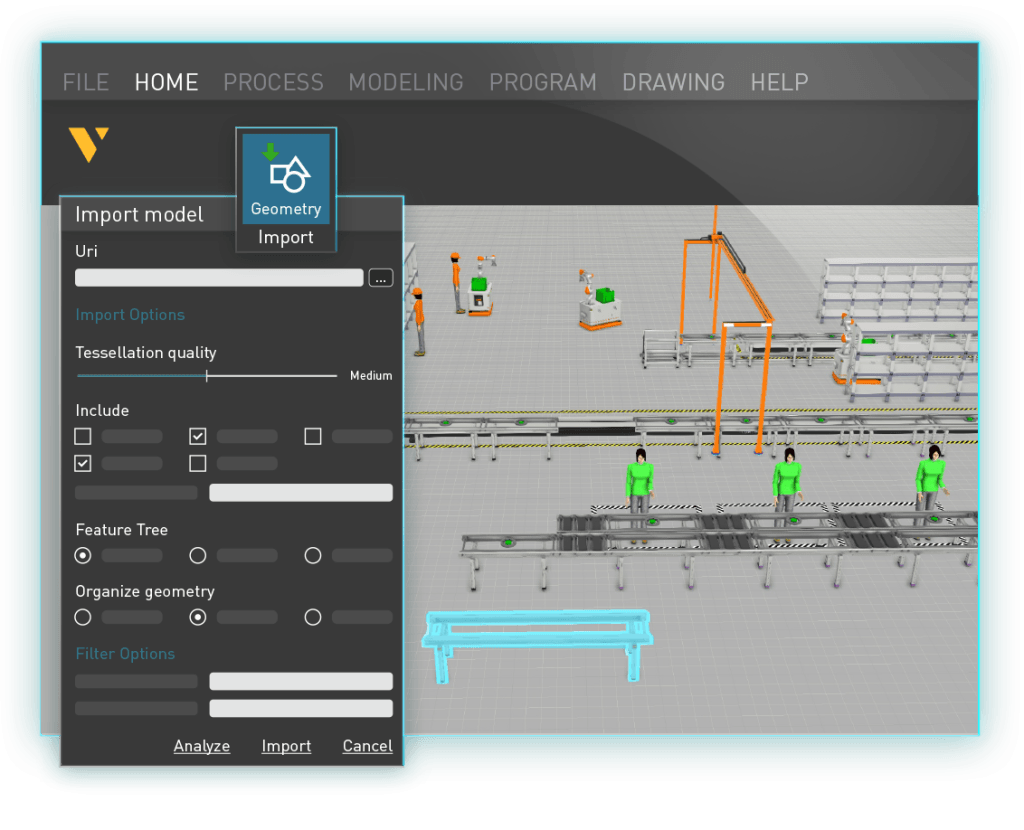

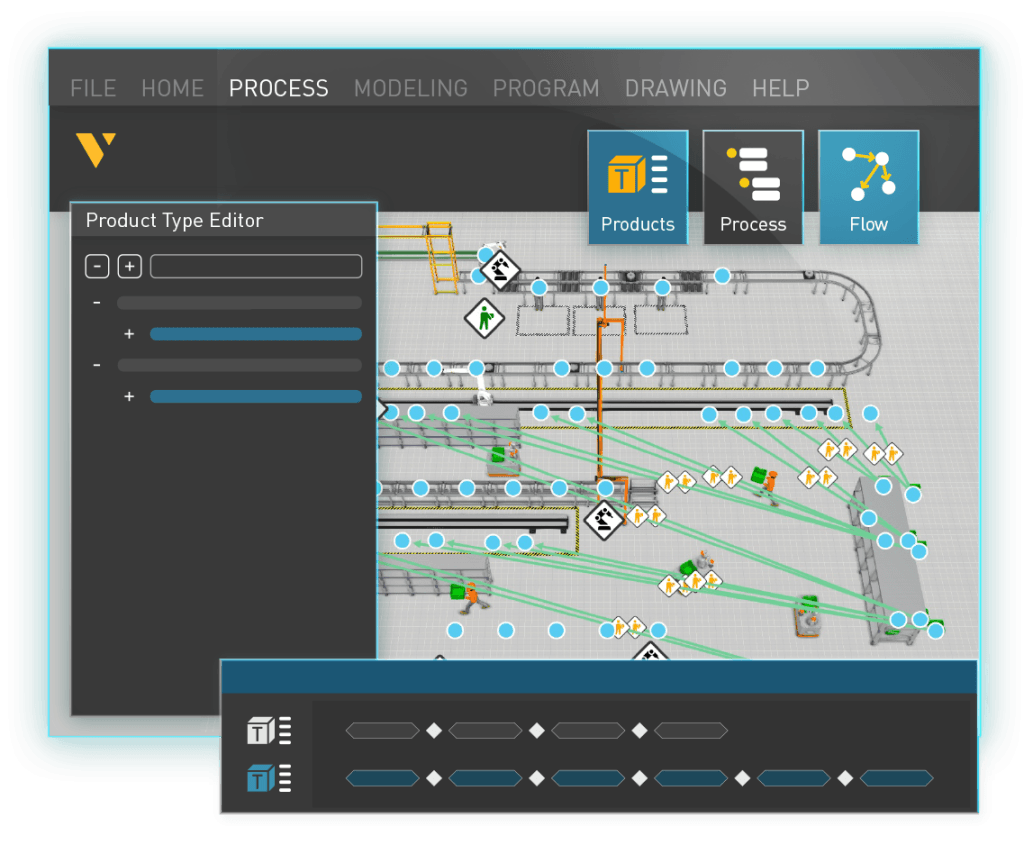

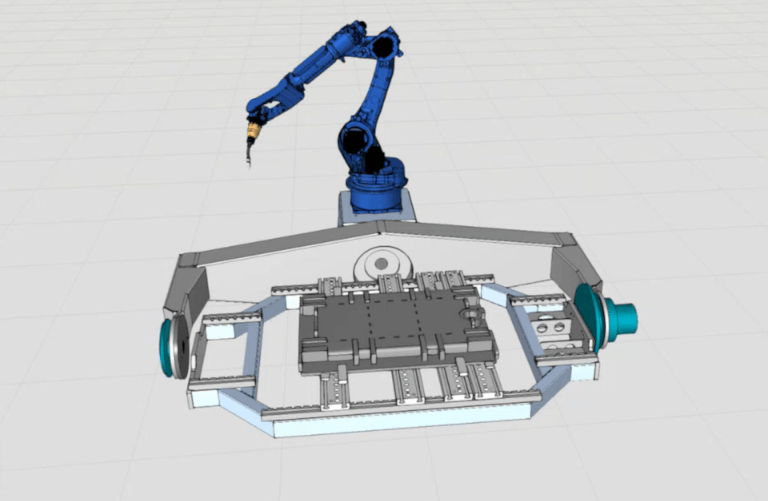

Efficiently program your robots for diverse tasks like welding, processing, spraying, jigless assembly and part handling and assemblies on a unified platform.

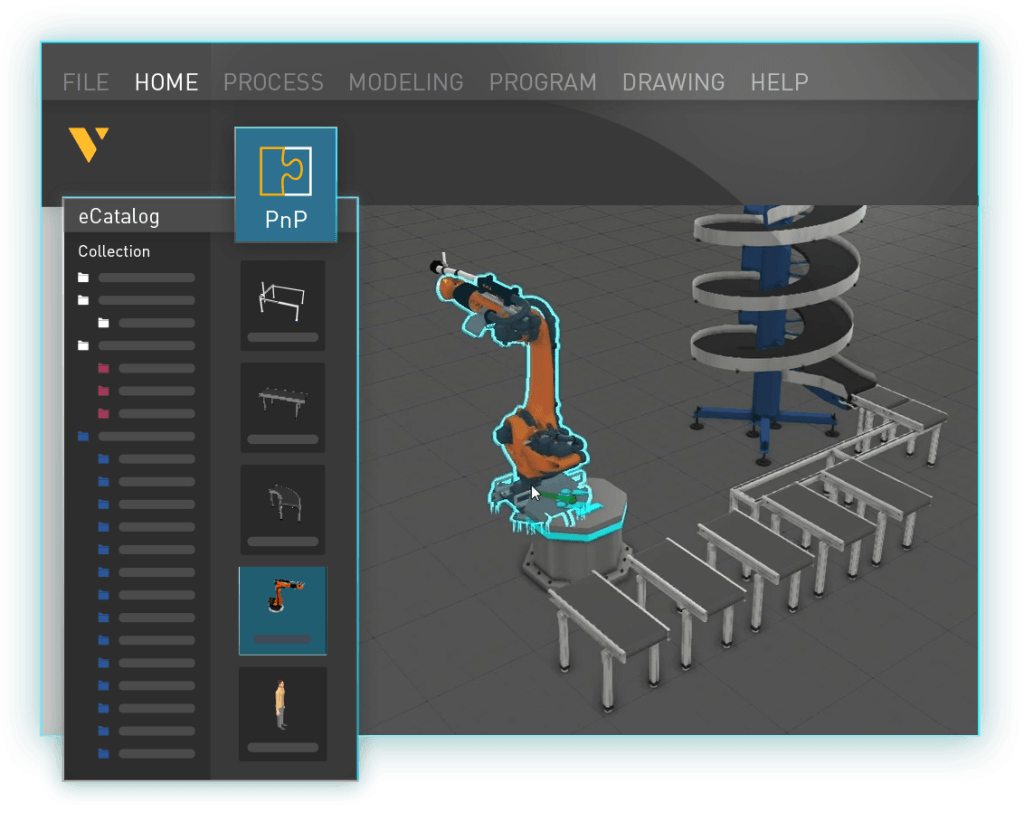

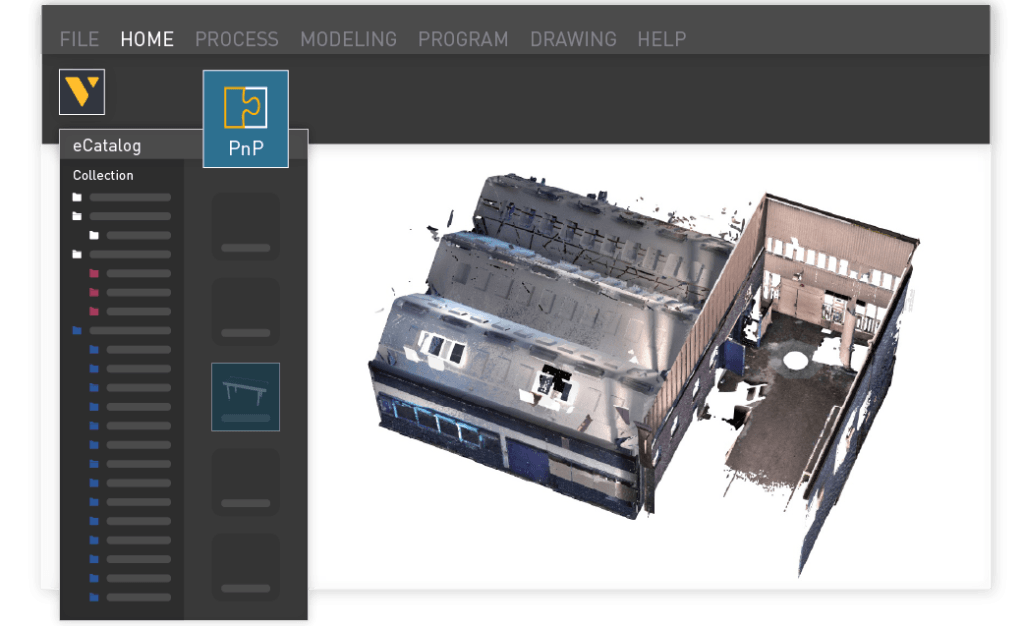

Easily program layouts from a single robot to multiple robots and robotic assembly operations with unlimited robot axes and over 3,000 ready-to-use components in our eCatalog using a single software.

Consistent quality with excellent accuracy

Inconsistencies and errors compromise the repeatability of quality. Robot programming software should enable repeatable quality with accuracy and minimal waste from manufacturing design to production.

Accurate and error-free programs

Easily calibrate robot layouts for accurate virtual-physical alignment. Let the software validate and optimize programs, eliminating costly production errors, part loss and risk.

Process knowledge database

Save your programs and re-use them anytime in the future for other projects and knowledge sharing.

Manufacturing feasibility

Eliminate last-minute modifications to fixtures and tooling, ensuring a smooth production process without unexpected delays and risks. Thoroughly test and adjust virtual models of the production setup well in advance of actual production.

Decades of customer excellence meeting the most demanding needs

Bunorm Maschinenbau: mastering complex welding quality and efficiency

Learn how Visual Components OLP helped program and optimize complex parts before production, leading to faster programming and improved quality.

Ponsse: driving forest machine innovation and improving productivity

Learn how Visual Components OLP helped enhance automation utilization, maximize productivity and streamline robot cell design.

Berlin Gardens: unlocking full potential of robotic welding in aluminum production

Learn how Visual Components OLP helped program robots for complex tasks with consistent speed and quality.

Robot offline programming FAQ

Leverage 17 robot post-processors from globally recognized robotics brands and 40+ robot controllers from traditional legacy robots to the latest models.

Full list of robot post-processors: ABB, CLOOS, Comau, Doosan, FANUC, Hyundai Robotics, IGM, KUKA, Kawasaki, Nachi, OTC Daihen, OMRON, Panasonic, Reis Robotics, Siasun, Stäubli, Universal Robots, Yaskawa.

Our eCatalog provides over 3,000 ready-to-use components, including 1,900+ robots from 60+ robot brands.

Yes, our software creates ready-to-use programs. Easily convert statements into lines of code with our post-processors for 17 robot brands. Download the ready-to-use program to physical robots on the shop floor for real-time execution to reduce commissioning time.

Robot programs generated in Visual Components are error-free and do not require rework, especially when using our seam searching feature. However, if necessary, the programs can be freely modified, adapted and validated on teach pendants.

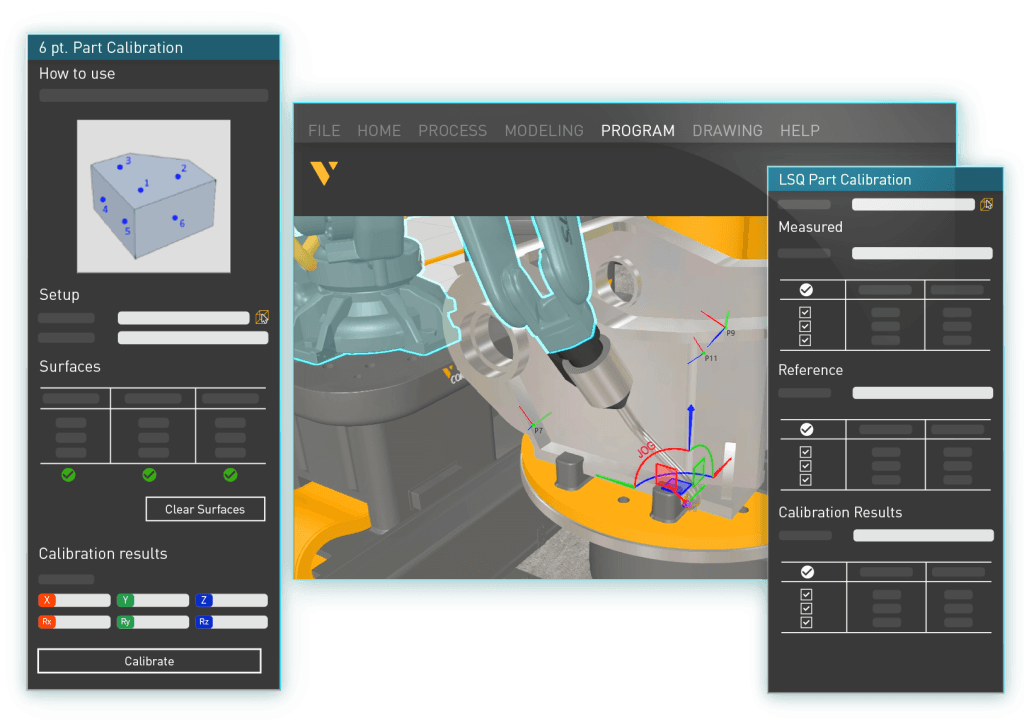

Leveraging our 30+ years of industry experience, we will ensure accuracy and success for your project. The effectiveness of OLP depends on how accurately the 3D simulation model (CAD model and kinematics) of a layout represents the real work cell. To capture the real layout of the cell, not just what’s represented in CAD, users must perform a process known as robot cell implementation and commissioning. We will build the virtual layout of your robot cells, calibrate the virtual layout with the actual robot cells and test that everything works on the robot cell.

During the implementation process, it is necessary to build the 3D layout of the robot cell and configure the initial information to match the real robot cell. Offline robot cell needs to be also calibrated according to the calibration measurements done with the real robot cell. Once the station is calibrated, we will test that together with end-users to ensure the validity of the process. Depending on the complexity of the robot cell, this process typically takes 4 to 8 working days.

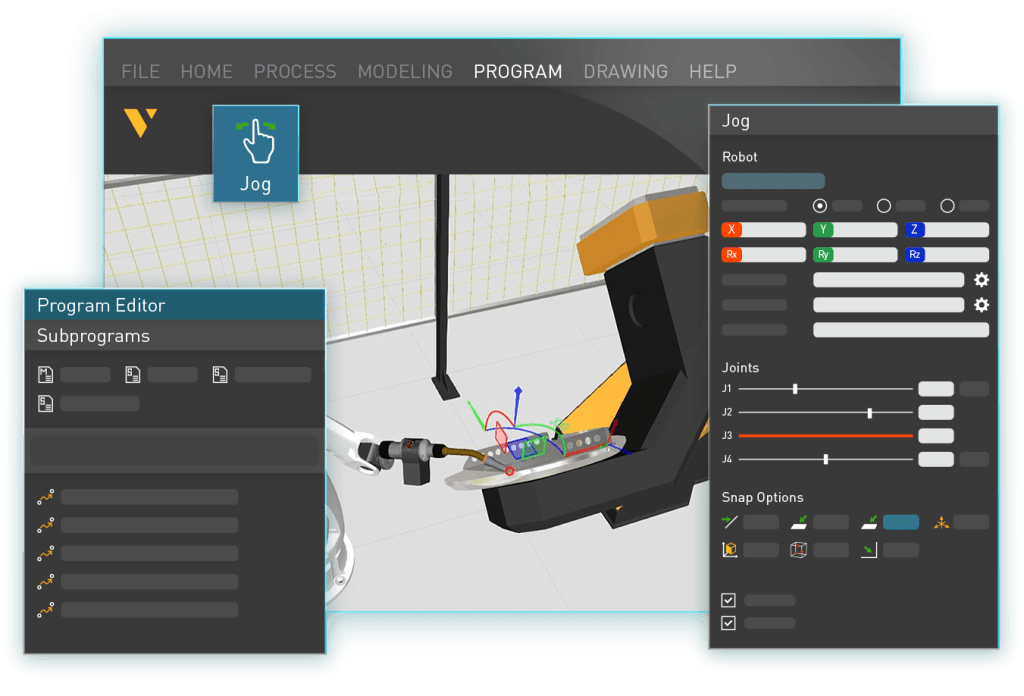

Visual Components OLP software does not require any programming or Python knowledge as we offer a drag-and-drop interface. One of our users had no prior computer experience and managed to use our software to reduce robot programming time.

Yes, by simply choosing the weld statement, then clicking the multipass button, you can adjust the settings or use a preset to generate programs for multi-layer welding seams.

Absolutely, you can build your layouts by choosing from over 3,000 ready-to-use components in our eCatalog. Our software can handle any complexity.

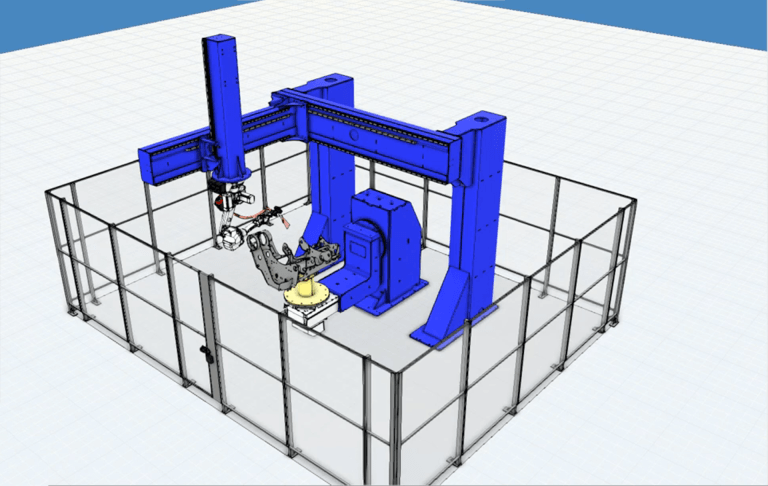

You can create layouts of robot systems of any complexity without restrictions on the total number of axes in Visual Components OLP software. This flexibility allows for the incorporation of auxiliary and external axes, multi-axis workpiece positioners and assembly portals.

With our turnkey solution, we provide all the necessary training and support to ensure a successful project. This includes delivering licenses, offering calibration and commissioning services for our software to ensure compatibility with the customer’s robot cell, and providing training for end users. We also offer ongoing technical support, new version releases, comprehensive user manuals and access to our online Academy and Extranet to support self-learning.

Design simulation models and self-commission robots with Professional OLP

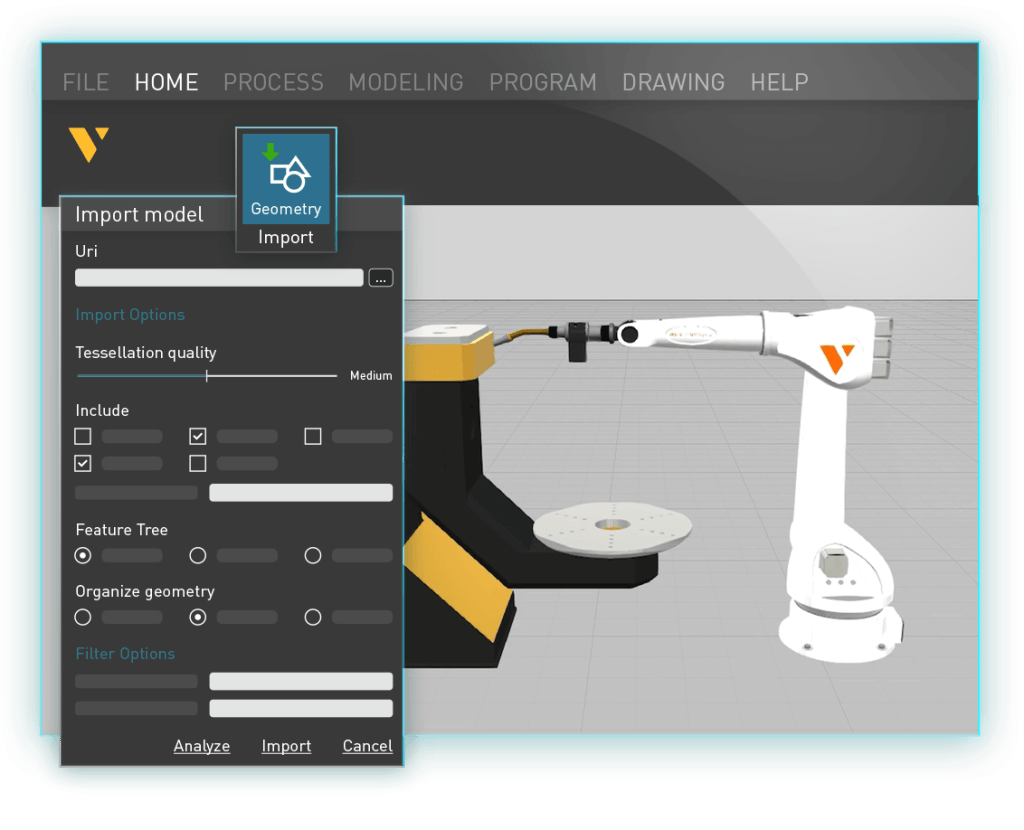

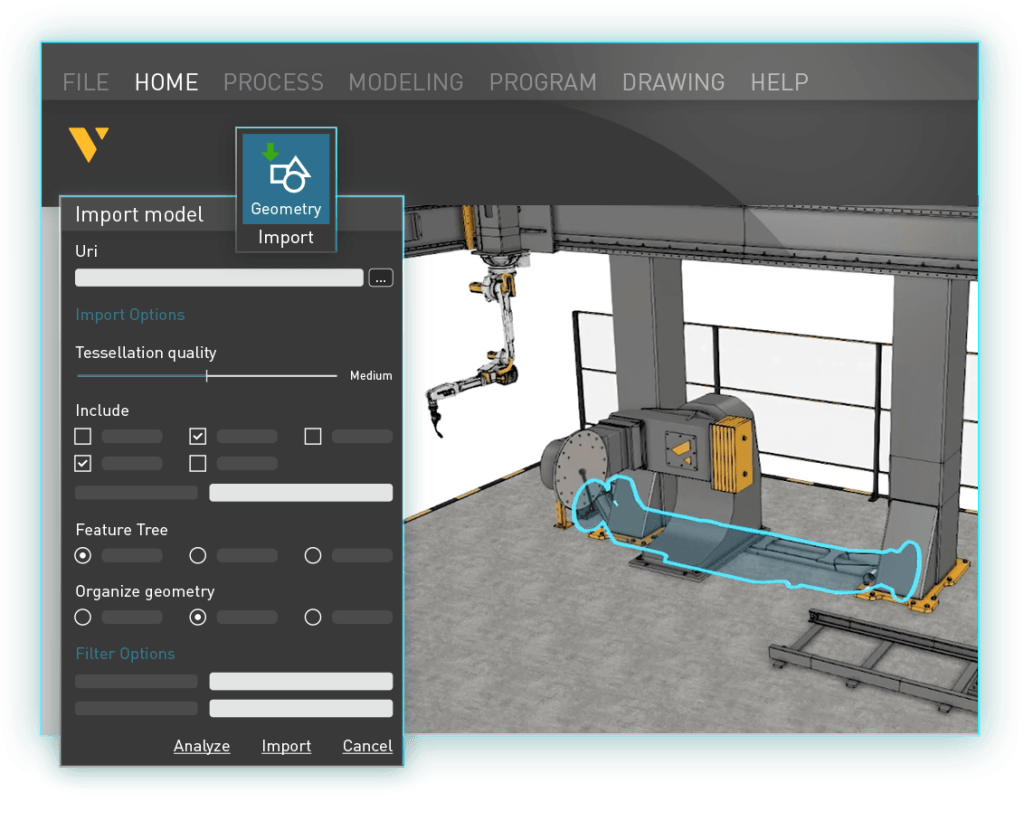

Convert your CAD data to simulation models

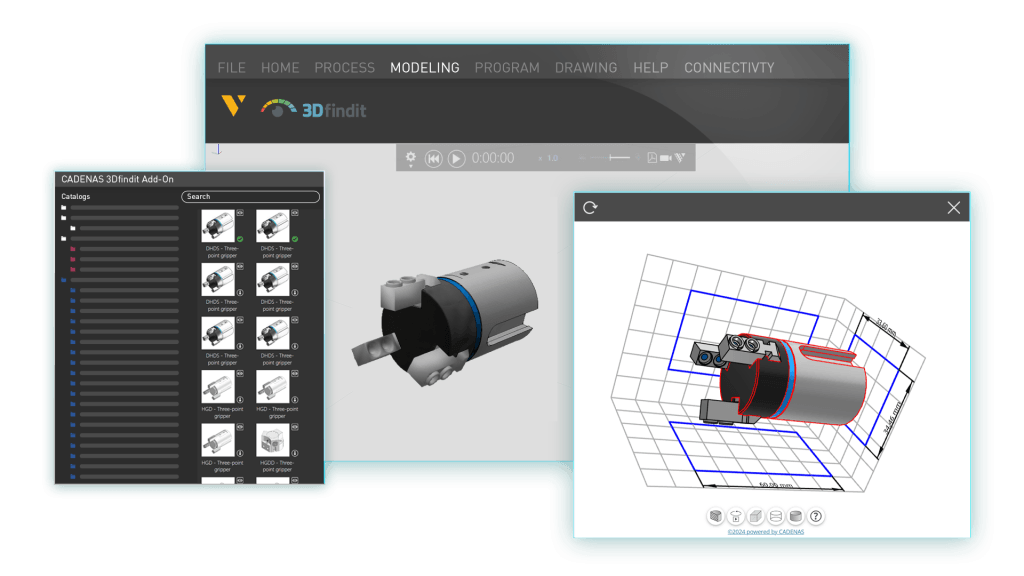

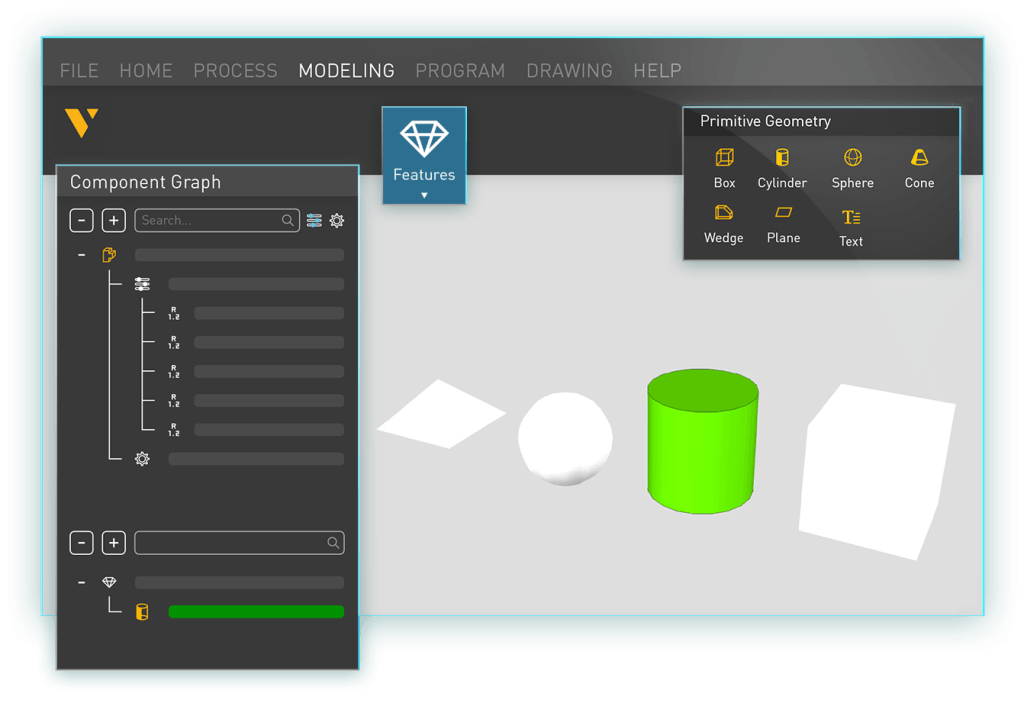

Design and simulate realistic manufacturing applications with easy-to-use modeling features. Create 3D geometries from scratch, import your existing CAD data, or modify any available components from our library and convert them into simulation-ready models.

Need to create intersections, unions or subtractions of CAD models? Our Boolean Modeling operations have you covered. Modify your CAD geometries for advanced simulations with ease.

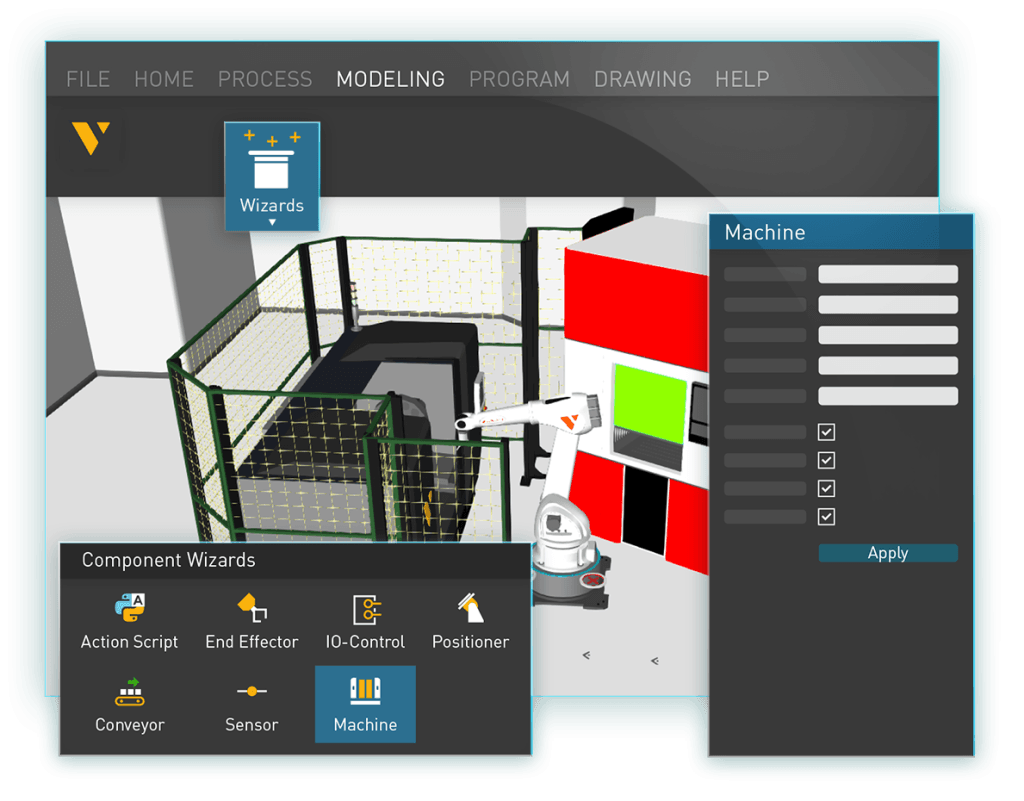

Streamline your component development with our pre-built functionality plugins. Just provide simple inputs and let our tools configure component behaviors automatically.

Save time and quickly activate your CAD files for the 3D world. Build new 3D geometries or update imported 3D models effortlessly using our modeling toolkit, all within the product.

Boost simulation performance by simplifying your models and removing unnecessary details. Enjoy reduced file sizes and faster simulations.

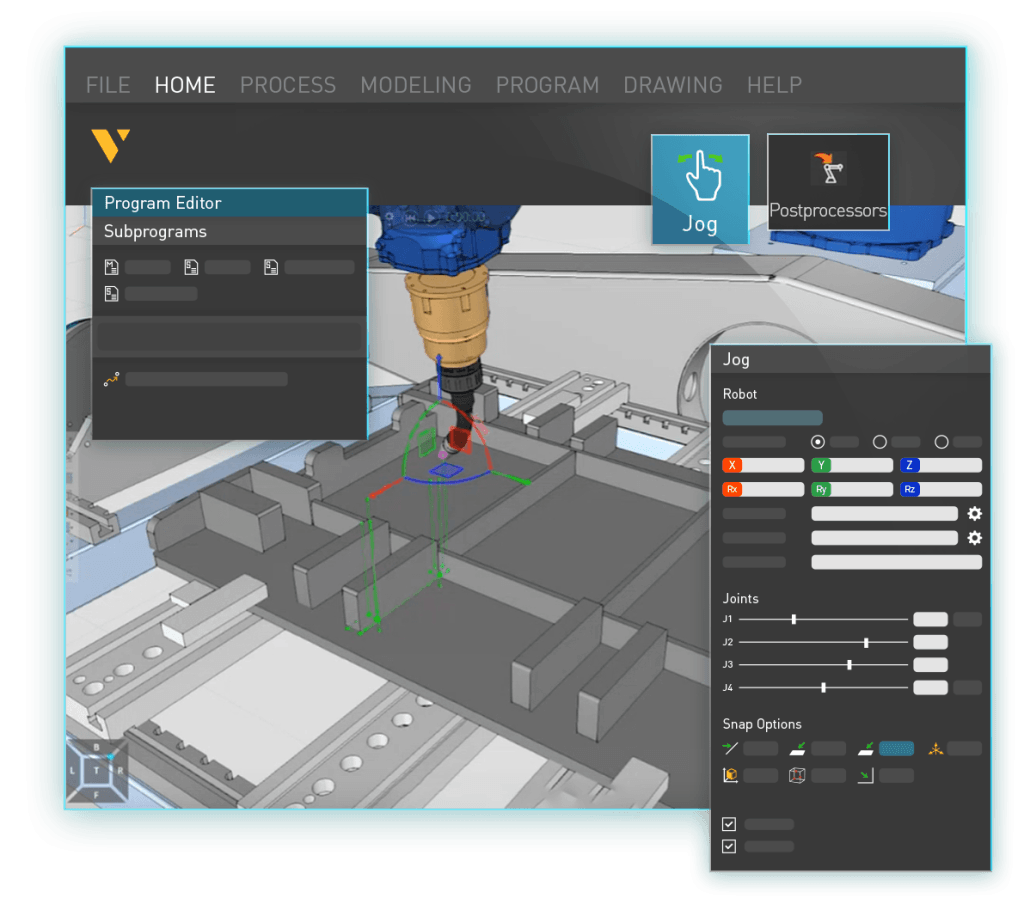

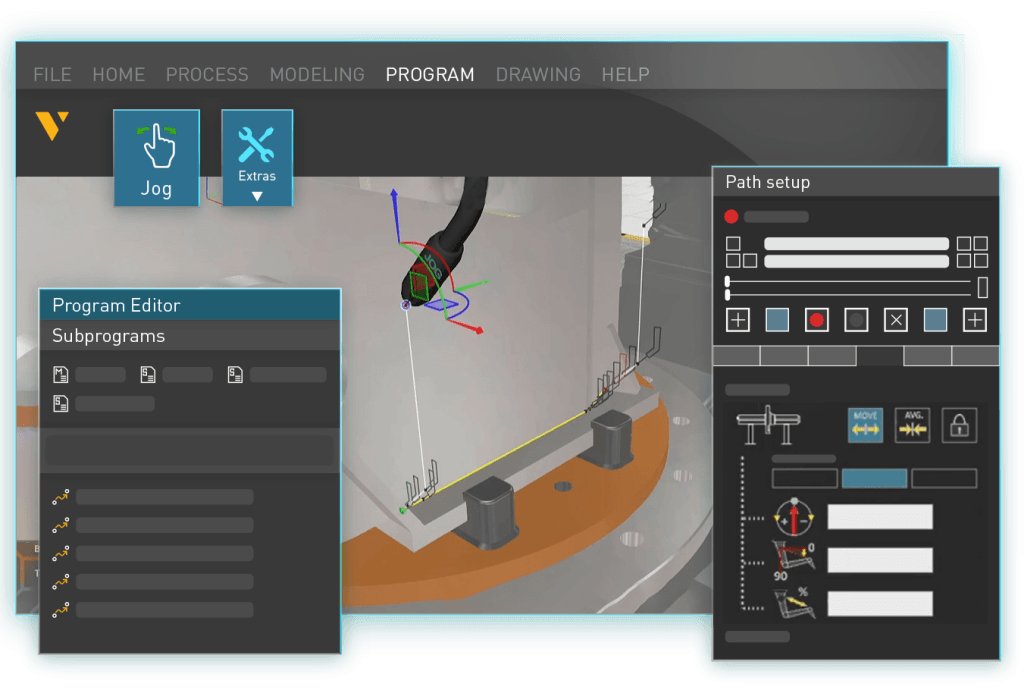

Extended OLP calibration tools

Self-commission robot cells with intuitive calibration tools including robot-to-robot calibration. Precisely calibrate robots, external axes and workpiece positioners with guided instructions and detailed reporting. Match the virtual layout with real-world layout to ensure robot programs function accurately for a faster production ramp-up.

Streamline your calibration process for success through intuitive, user-friendly interfaces.

Get instant analysis and reporting of calibration results and minimize the time spent on troubleshooting on-site.

Bring virtual projects to reality with Premium OLP

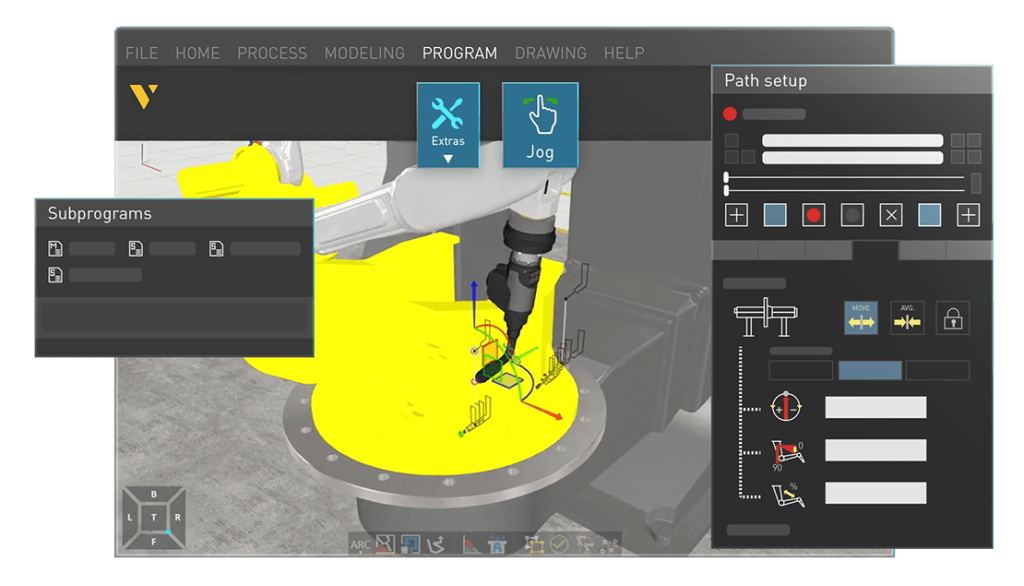

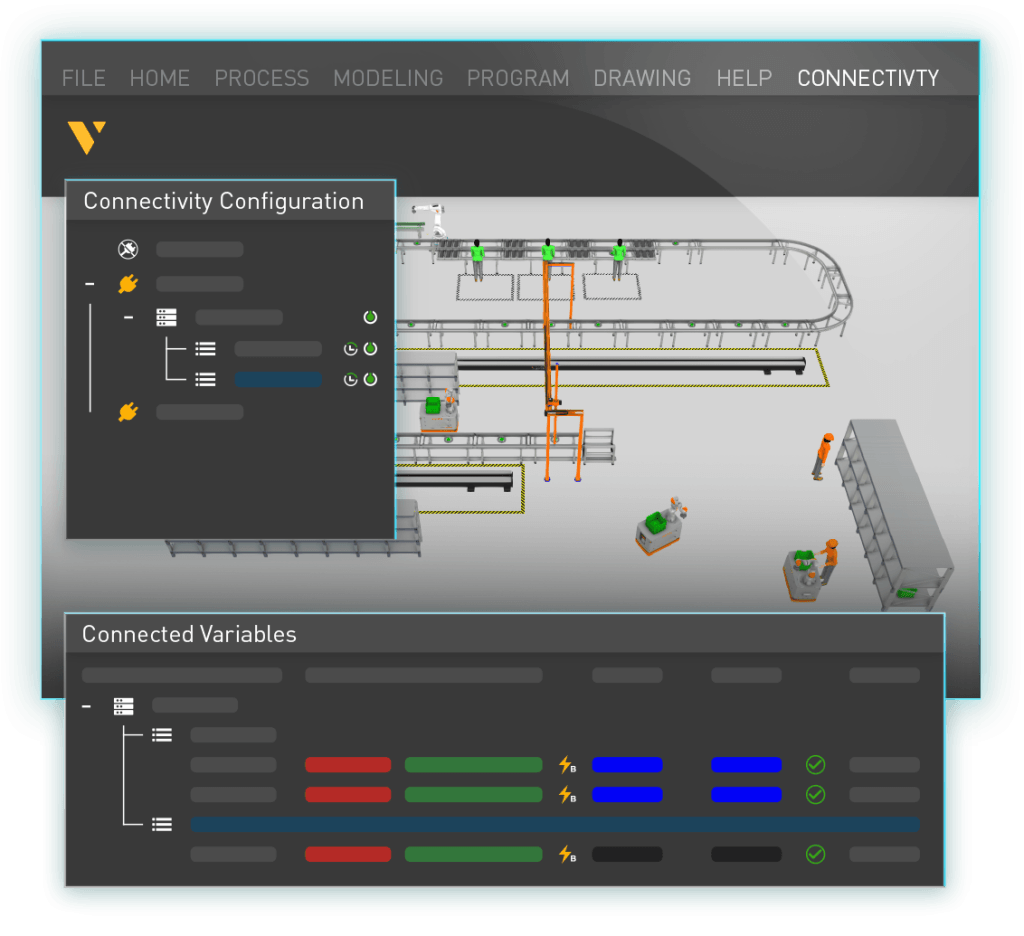

Enhanced virtual commissioning

Connect your simulations with a range of physical and virtual vendor-specific controllers to plan, debug and verify your programs with powerful visuals and improve virtual commissioning possibilities.

Program KUKA robots in KUKA Robot Language (KRL) using the Visual Components robot program editor. Seamlessly transfer your projects to KUKA virtual controller (KUKA.OfficeLite) and physical controllers. Enhance your virtual commissioning with precise cycle times, accurate robot paths and advanced collision detection.

Connect your simulations directly to ABB, Doosan, FANUC, Kawasaki, OMRON and Yaskawa robots using their respective physical controllers or robot software. Validate your programs with precise cycle times and robot paths, and remotely monitor the performance of your manufacturing systems, ensuring optimal efficiency and accuracy.

Siemens S7 PLC Connectivity supports native connectivity to most physical and simulated Siemens PLCs, including older models. This native connection ensures faster communication speeds with physical S7-1200 controllers and supports connections to S7-PLCSIM.

WinMOD and SIMIT connectivity plugins enable communications with several physical and virtual automation systems. Verify your PLC programs and robot kinematics by connecting with many vendor-specific controllers. SIMIT connectivity opens the door to the complete range of Siemens automation systems including PLCSIM Advanced, PLCSIM, Virtual Controllers, SIMIT UNIT and PLCs.

Quickly create and share designs by exporting them in the FBX format. Includes the ability to export skeletons and joint limits of your 3D objects. Additionally, you can also export animations, providing a more dynamic and interactive view of your designs.

Find the right product for your needs

Whether you’re looking for a tool to program your robots or quickly design and present production solutions, we’ve got you covered. Check out our family of 3D manufacturing simulation and robot offline programming products.

Robotics OLP

Maximize quality, robot utilization and output with the fastest, easiest, universally compatible offline programming software.

- Work piece and jig geometry import

- Automated solver for process and via paths

- Robot programming for all processes

- Robot post-processors for all brands

- OLP calibration tools

Professional OLP

Design your own simulation models for custom applications. Program robots and self-commission robot cells with accuracy.

- All features in Robotics OLP

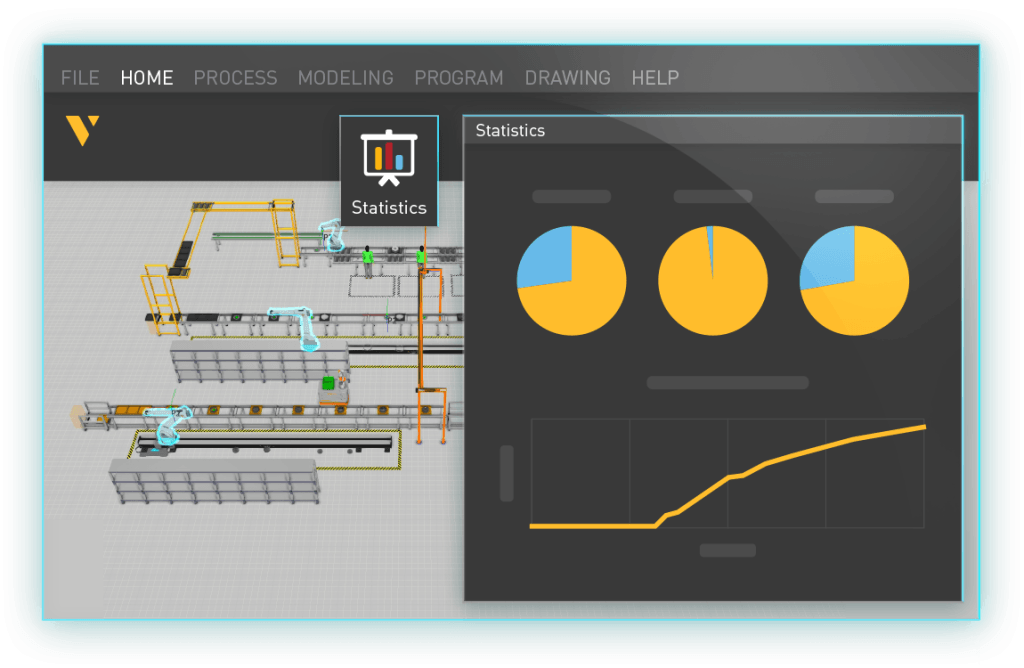

- Factory simulation

- Process modeling

- Basic PLC connectivity

- Custom modeling with parametrics

- Extended OLP calibration tools

Premium OLP

Bring your virtual projects to reality through this complete simulation and offline programming solution.

- All features in Robotics OLP

- All features in Professional OLP

- Robot connectivity

- Advanced control systems integration

Compare products

Robotics OLP

Professional OLP

Premium OLP

Robot programming

Layout import and configuration

Factory simulation

Collaboration

Virtual commissioning

Looking for simulation tools? Check out our range of 3D manufacturing simulation software.