Industry solutions

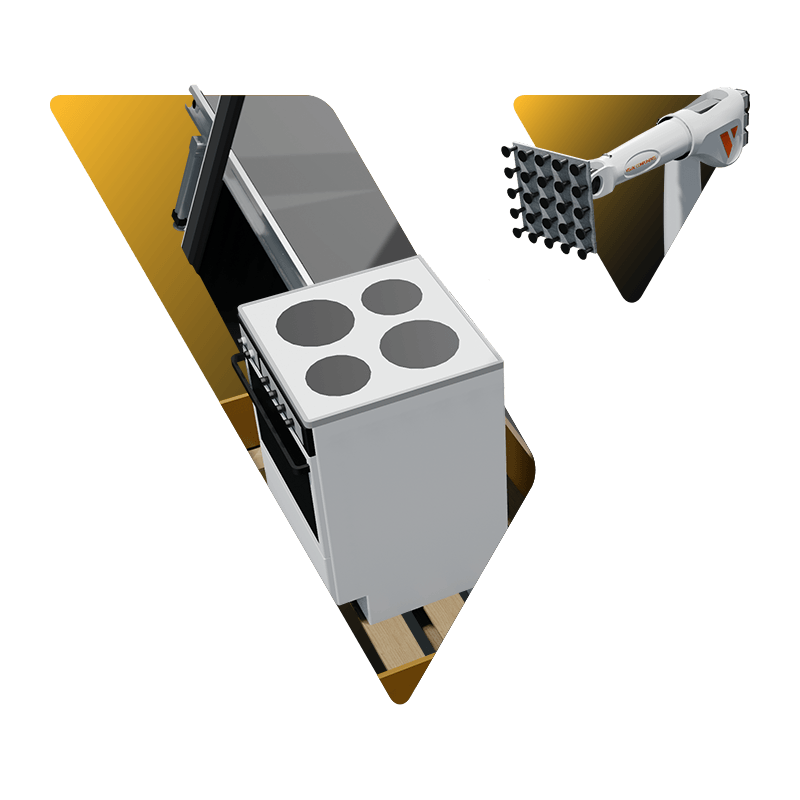

White goods

Accelerate your early design concepts with simulation, reduce the time to market and improve your responsiveness to new product introductions.

Why simulate with Visual Components?

Improved responsiveness

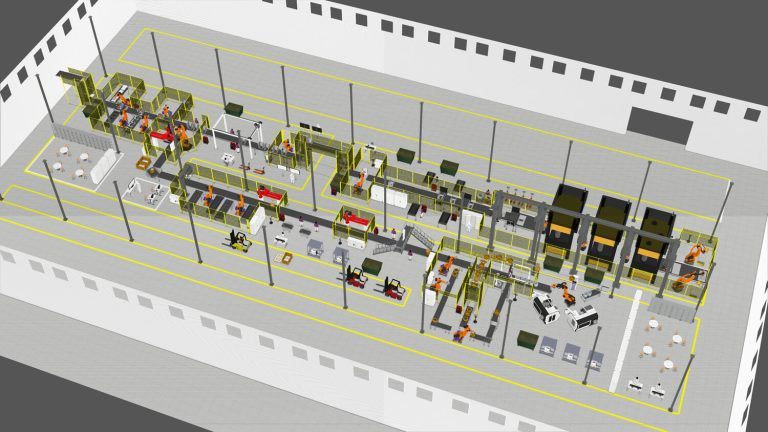

The manufacturers consistently face the challenge of adapting to the latest new product introductions with technical changes. Simulation with Visual Components improves the flexibility and adaptation of these technological advancements for the production systems.

Reduce time to market

Visual Components simulation saves time in the early concept design phase from days to hours. This enables the manufacturers to respond to consumer demands faster and reduce the time to market.

Improved communication

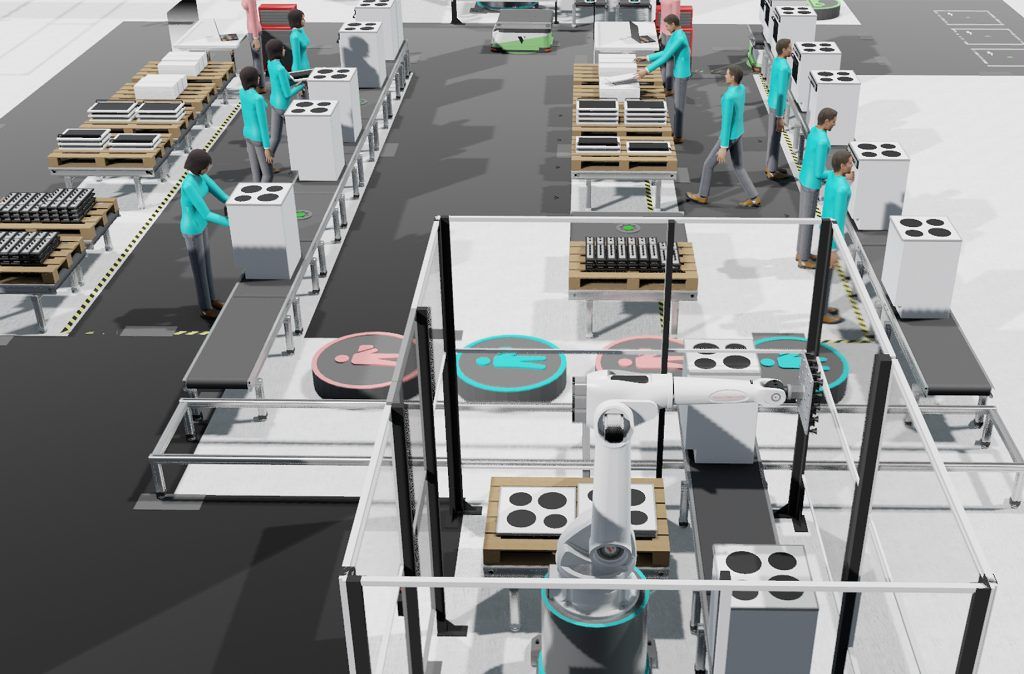

Visual Components 3D simulation improves the communication of plans across different channels in the production environment whether it is about communicating the process changes to the staff on the shop floor, convincing the decision-makers to invest in new equipment, or reconfiguration of any manufacturing process.

Visual Components for the white goods manufacturing industry

White goods encompasses both companies that manufacture large appliances like washers, dryers and refrigerators, and the businesses that supply their materials and manufacturing equipment. White goods manufacturers typically seek economies of scale to be competitive and profitable. Achieving this requires a broad product line with many variants and frequent new product introductions.

The challenges facing the white goods market are familiar: consumers want more price, features, and form factor options, along with the latest and green technologies. In the factory, manufacturers struggle with labor shortages and rising costs while seeking flexible automation to support high product variety and increasing complexity.

How is Visual Components used in the white goods industry?

How Midea enhanced washing machine production with Visual Components

See how Midea used Visual Components to increase the capacity and flexibility of a high-end washing machine assembly line, while reducing costs by 15%.