Industry solutions

Packaging and palletizing

Use simulation to invest smartly in your next production upgrade. Improve your chances to close deals with a powerful sales acceleration tool.

Why simulate with Visual Components?

Optimize floor space

The workspace demands for packaging and palletizing processes could easily escalate in a complex production process. Visual Components helps in reconfiguring the layouts to optimize the use of floor space.

Maximize utilization of manufacturing assets

The packaging and palletizing are typically fast-paced operations where any machine breakdown requires quick actions to redirect and reschedule the production flow. Simulating with Visual Components helps in managing such production queues and downtimes.

Improve sales acceleration of automation projects

Visual Components is a powerful sales acceleration tool for testing and validating different packaging and palletizing setups to select the most productive configuration. System integrators can use Visual Components to sell the most optimal automation plans to manufacturers that consistently face challenges like tight scheduling and high output demands.

Visual Components for the packaging and palletizing industry

Packaging protects, preserves, informs, and sells and is closely associated with the identity of the products it contains. Packaging equipment takes many forms, from carton erectors and bottle fillers to systems that palletize boxes, sacks, and pails for shipping. Also included in this category is the manufacture of packaging materials and the equipment for making the materials themselves.

Packaging and packing equipment manufacturers are increasingly challenged to minimize weight and volume while still protecting and differentiating the product. This takes specialized equipment that’s sold in a highly competitive global market. The drive towards more automation and flexibility also means that these operations are becoming increasingly complex.

How is Visual Components used in the packaging and palletizing industry?

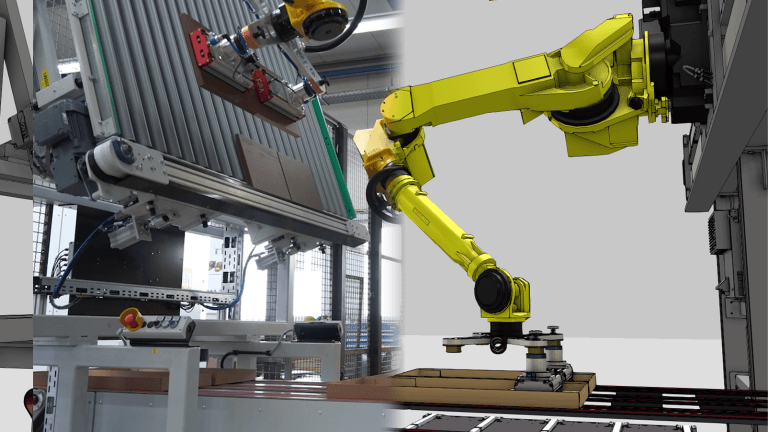

Packaging perfection: navigating variations in furniture packaging with Visual Components

The furniture industry has shifted from handcrafted pieces to mass-produced, self-assembly models made from materials like MDF or chipboard. This change has complicated packaging due to the need for high-volume…

3D packaging simulation success stories with DHL

See how DHL, the world’s largest logistics company uses Visual Components manufacturing simulation to power the adoption of automation in the age of accelerated digitalization.

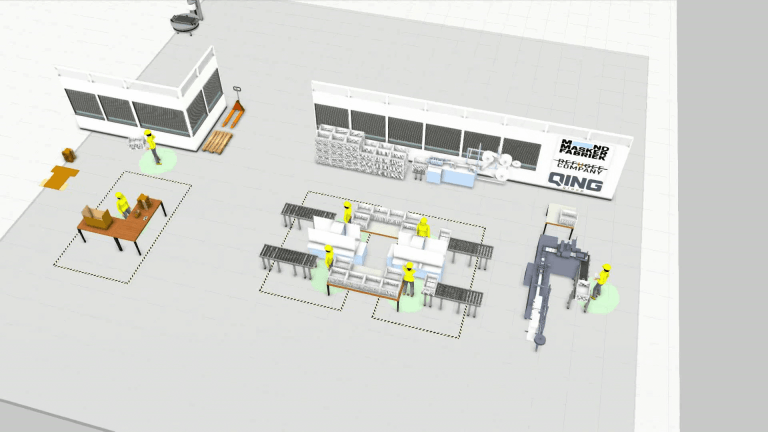

QING Case Study: Using 3D Simulation Technology to Set up a Face Mask Factory During the COVID-19 Pandemic

In this case study, we’ll examine how QING used 3D manufacturing simulation to set up a fully functional face mask factory in the Netherlands within just a few weeks to…