Industry solutions

Intralogistics and warehousing

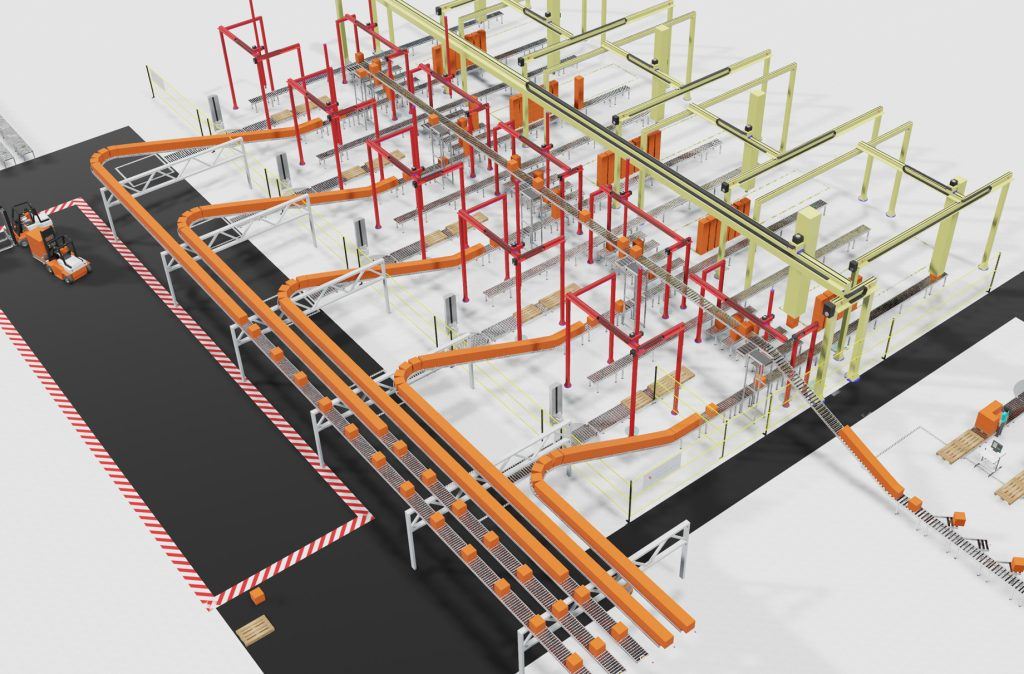

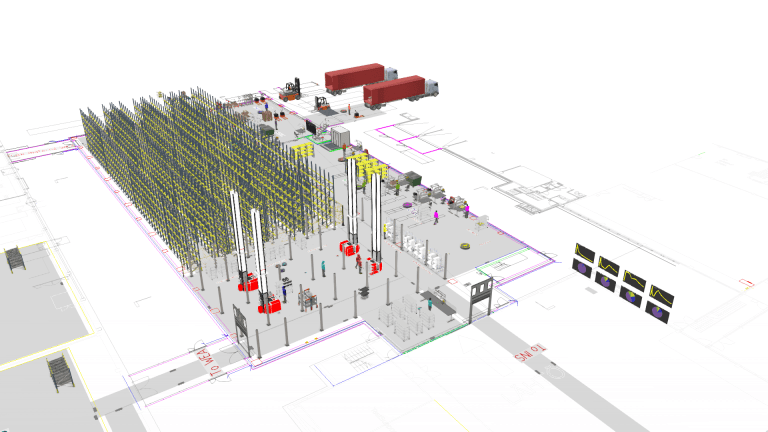

Simulate to organize your warehouses and increase the functionality of your intralogistics setups with synchronized operations.

Why simulate with Visual Components?

Well-integrated operations

Simulating with Visual Components highlights the bottlenecks in the logistics operations and offers smooth integration among different warehousing units. This helps in synchronizing the processes and streamline several tasks.

Organize the warehouse layouts

In a typical fast-paced and complex warehousing operation, several resources work together at the same time in the same space. This makes it hard to organize the warehouse layout and usually ends up interrupting the production flow. Visual Components enable smooth implementation of the process flow by a better organization of resources and their routes.

Improve the warehousing functionality

The number of products in intralogistics and warehousing facilities are usually very high that results in a complex material handling process. Simulation with Visual Components helps in improving the functionality of the warehousing systems and also categorizes and prioritizes the layouts based on the product demands.

Visual Components for the intralogistics and warehousing industry

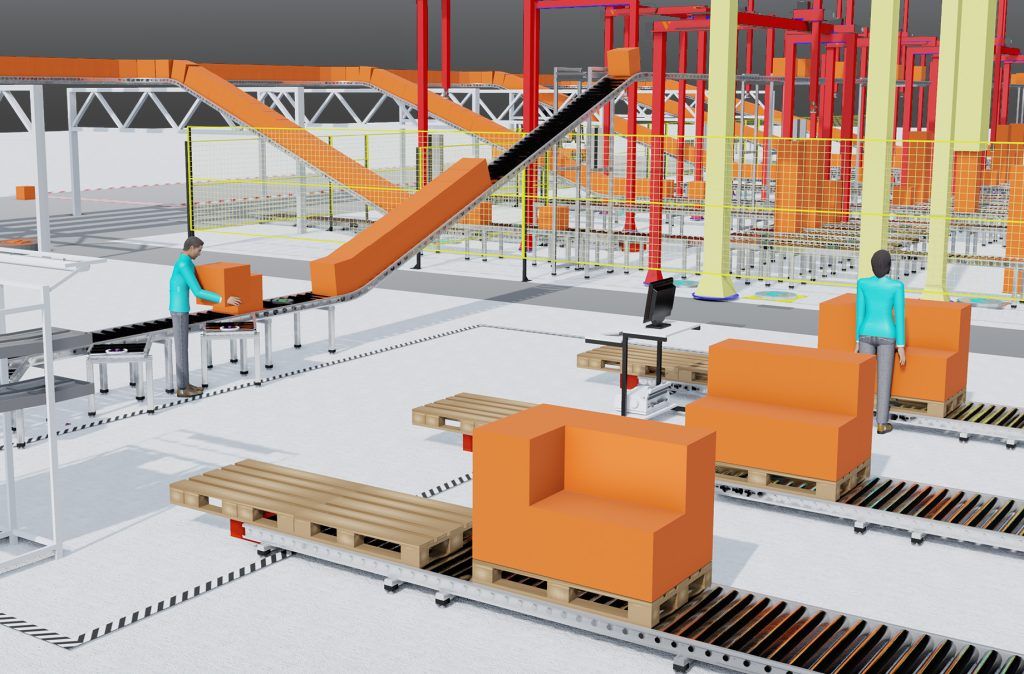

Supply chains are global and e-commerce is driving dramatic growth in warehousing, distribution, and logistics operations. Everything needs shipping, storing, picking, consolidating, and rerouting before being transported to its final destination. Driven by increased competition, expectations for shorter delivery times, and advances in material handling technologies, the modern-day supply chain is technology-driven and increasingly automated.

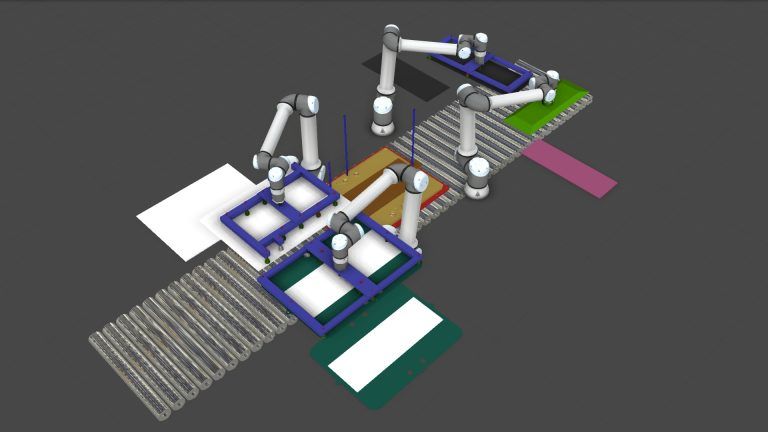

One of the biggest challenges is picking efficiency. Pickers can walk miles each day, during which time they’re not picking and can make mistakes. Other challenges include minimizing labor expenses, (recruitment, turnover, and training as well as employment costs), and accelerating the velocity with which goods enter and leave.

How is Visual Components used in the intralogistics and warehousing industry?

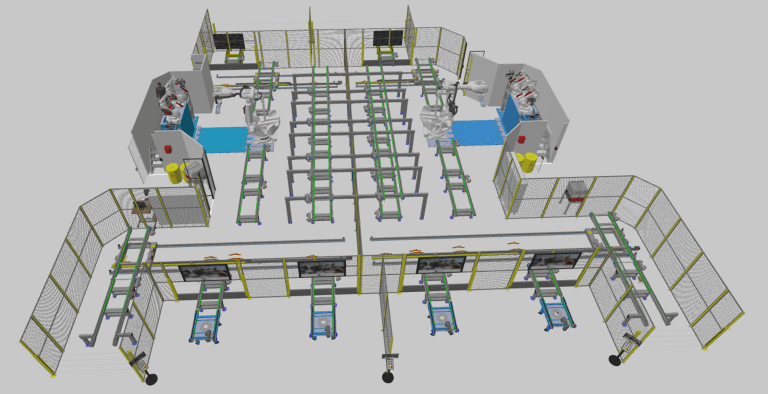

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

How ECOSPHERE helped JenaBatteries automate redox flow battery production with Visual Components

If more green energy is to be generated from the sun and wind, electricity needs to be stored for dark and windless times. To meet this challenge, innovative solutions are…