Industry solutions

Industrial automation

Use hundreds of free-to-use automation equipment models from known global brands to set up realistic simulations of your automation projects.

Why simulate with Visual Components?

One-stop shop

We offer an easy-to-use 3D simulation platform that not only provides layout configuration tools but covers complete automation applications with a vast component library, offline robot programming, virtual commissioning, and virtual reality (VR).

Smarter investment decisions

Our brand agnostic approach in the component library offers a unique platform where manufacturers can test and validate their plans with real automation equipment. Choose the equipment from any manufacturer and make smarter investment decisions by calculating payback time and ROI.

Improved communication

Visual Components help the manufacturers and system integrators with the effective execution of automation plans by improving the communication of the process changes whether it applies to the production staff or customers.

Visual Components for the industrial automation industry

The industrial automation equipment market is global and highly competitive. In the Industry 4.0 era it’s also experiencing a period of significant innovation. Customers are pushing for more advanced, customized, and connected solutions, which is driving machine builders and integrators to partner more closely on both solution design and sales.

These manufacturers face many challenges. First is the growing list of environmental regulations taking hold around the world. Sustainable building practices, improved air quality, and reduced emissions have become a major driver behind product design and development. Health and safety standards are also evolving, placing new burdens on manufacturers already battling with a shortage of skilled labor.

How is Visual Components used in the industrial automation industry?

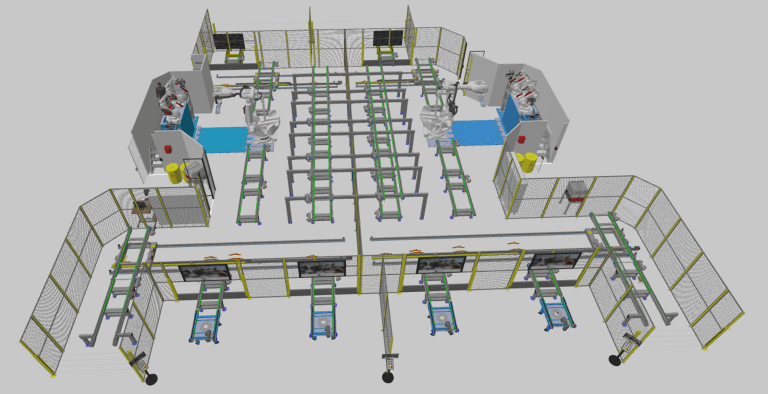

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

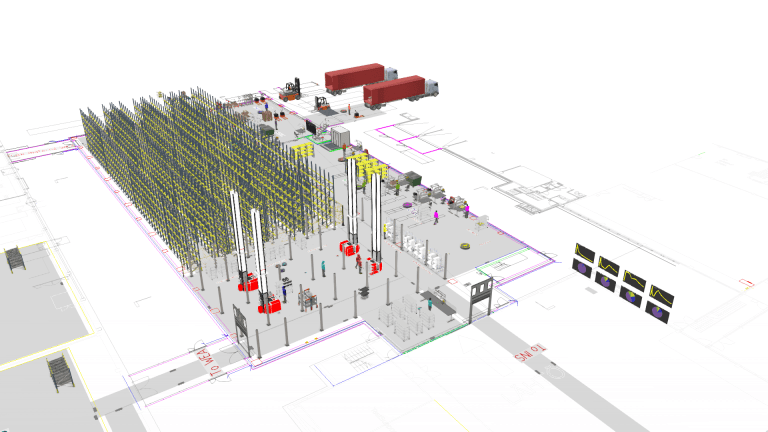

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

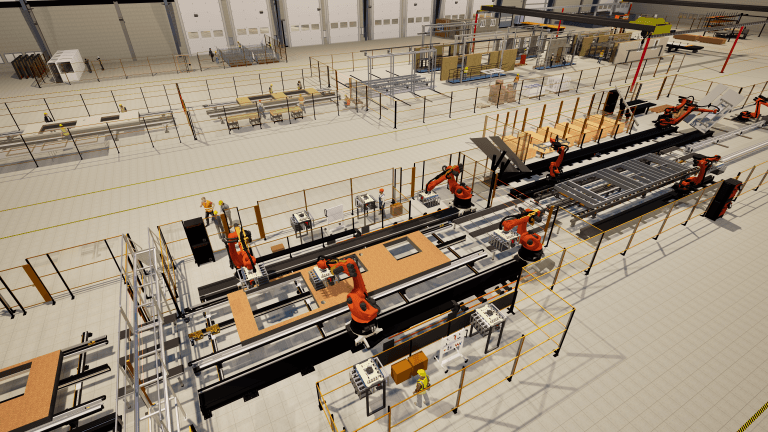

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more…