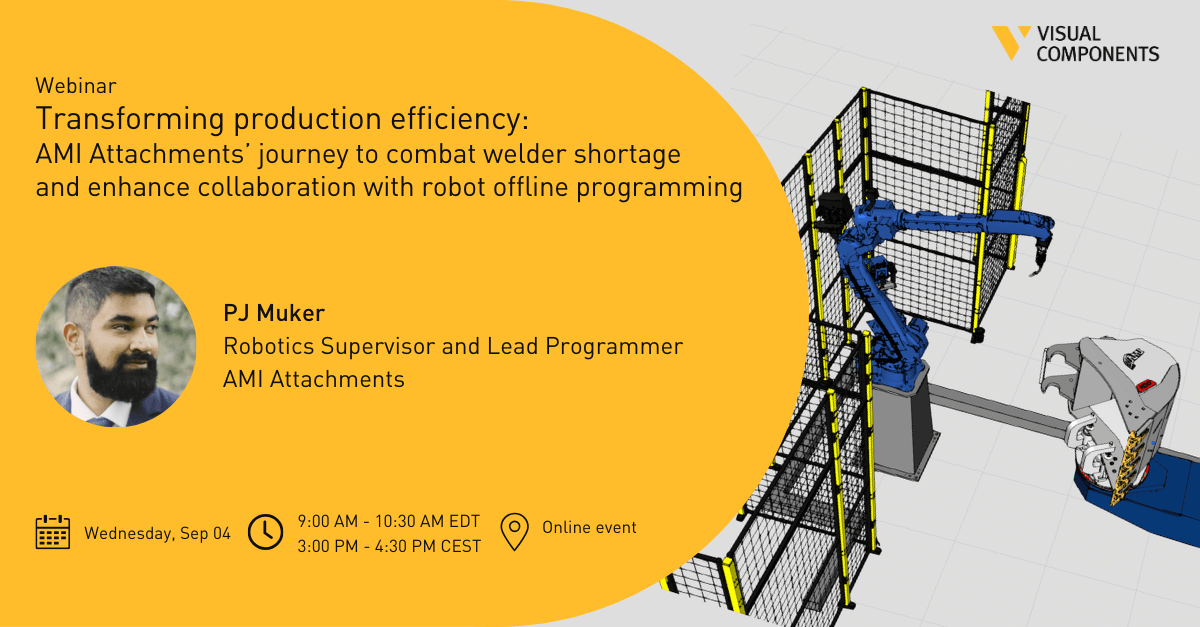

Transforming production efficiency: AMI Attachments’ journey with robot offline programming

Join our webinar with PJ Muker, Robotics Supervisor at AMI Attachments. Learn to boost efficiency and reduce downtime with robot offline programming.

- Date: 4.9.2024

- Location: Microsoft Teams

- Register now

Learn from the transformative journey of AMI Attachments (AMI), a leading manufacturer of heavy equipment attachments, as they maximize production efficiency and minimize downtime with robotic welding and robot offline programming (OLP). Discover how AMI overcame production challenges and a welder shortage by implementing Visual Components OLP software.

PJ Muker, Robotics Supervisor at AMI, will walk us through their transition from manual to offline programming, highlighting the significant reduction in programming time and improvements in collaboration and production quality. As the Lead Programmer, PJ will also share his expert tips and tricks through a live software demo with their workpiece.

This webinar will provide a comprehensive look at how AMI improved efficiency and became an international role model in the industry through their innovative use of offline programming and robotics.

Our Robotics Sim Expert, Montgomery Willett, will be available during the Q&A session to answer any questions you may have about OLP.

Speakers

PJ Muker

Robotics Supervisor and Lead Programmer

AMI Attachments

With about 10 years in robotics, PJ started as a Robotic Technician at Honda and Toyota, mastering PLCs and managing new equipment integration, new model production and troubleshooting in a plant with 500+ robots. Since 2021, PJ has been leading AMI’s robotics team, successfully commissioning 6 robotic weld cells.

Montgomery Willett

Robotics Sim Expert

Visual Components

Having worked as a Robot Programmer and Automation Technician at various manufacturers, Montgomery has nearly 15 years of experience in industrial robotics and automation. Leveraging his deep industry expertise, he provides advice and technical support to customers on robotics simulations and programming.