Automatica 2025

Automatica, held in in Munich, Germany from June 24-27 2025, is the leading exhibition for smart automation and robotics! Visit us at hall B5 booth 402!

- Date: 24.6. - 27.6.2025

- Location: Munich, Germany

- Keywords: automation, robotics, digitalization, AI, sustainable production

Automatica 2025

We are thrilled to announce our participation in Automatica 2025, the leading exhibition for smart automation and robotics, taking place from June 24 to 27, 2025, in Munich, Germany. As a key event in our industry, we are eager to present our latest innovations and solutions.

What to Expect at Our Booth

Visit us at Hall B5, booth 402, where we will be highlighting our expertise in advanced manufacturing simulation, robot offline programming technologies, and visual components. Our booth will feature:

- Interactive Demo Desks: Experience our cutting-edge technologies through hands-on demonstrations.

- Videowall Presentations: Learn about our latest advancements and how they can benefit your business.

- Expert Consultations: Meet our team of professionals who are ready to discuss your specific needs and provide tailored solutions.

- Networking Opportunities: Connect with industry leaders and peers to explore potential collaborations and partnerships.

- Special Highlights: Celebrate our 25th anniversary with us and discover our journey in manufacturing production design since 1999.

Why Attend Automatica 2025?

Automatica is the premier event for anyone involved in smart automation and robotics. It brings together key technologies and industry leaders, providing a platform for visionary exchange and showcasing the latest developments, topics, innovations, and solutions. This tradeshow is an excellent opportunity to stay informed about the latest trends and advancements in the industry.

Plan Your Visit

Don’t miss out on this opportunity to see our latest innovations and connect with our experts. Mark your calendar for June 24-27, 2025, and join us at Automatica in Munich. We look forward to welcoming you to our booth 402 and exploring how we can help you achieve your automation goals.

Meet the team

Mikko Salminen

Global Sales Director

Mikko Salminen is the Head of Global Sales at Visual Components, bringing over 24 years of extensive experience in the manufacturing industry.

A pioneer in the field of 3D manufacturing simulation, Mikko has been leveraging simulation technologies since 1997 and integrating them into his professional work since 2001. His deep expertise has evolved from being an end user to a trusted advisor, helping businesses maximize value through cutting-edge simulation to optimize production performance and drive operational excellence.

Matthias Wilhelm

Sales Director DACH and Team Lead

Matthias Wilhelm is Sales Director DACH at Visual Components and leads the German office of Visual Components GmbH based in Munich.

Together with his team he develops innovative strategies. He uses his keen instinct for solutions and added value that can be achieved through robotics and automation to advise companies and interested parties on how to achieve their goals. As a qualified mechanical engineer with a focus on the automotive industry, Matthias Wilhelm has built up an extensive network and in-depth expertise through his previous roles at companies such as Continental, ASCAD, CENIT AG and Autodesk. He uses this to successfully plan and optimise complex automation, factory and production projects.

Get here your free ticket for “Automatica”

AVAILABLE SOON

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

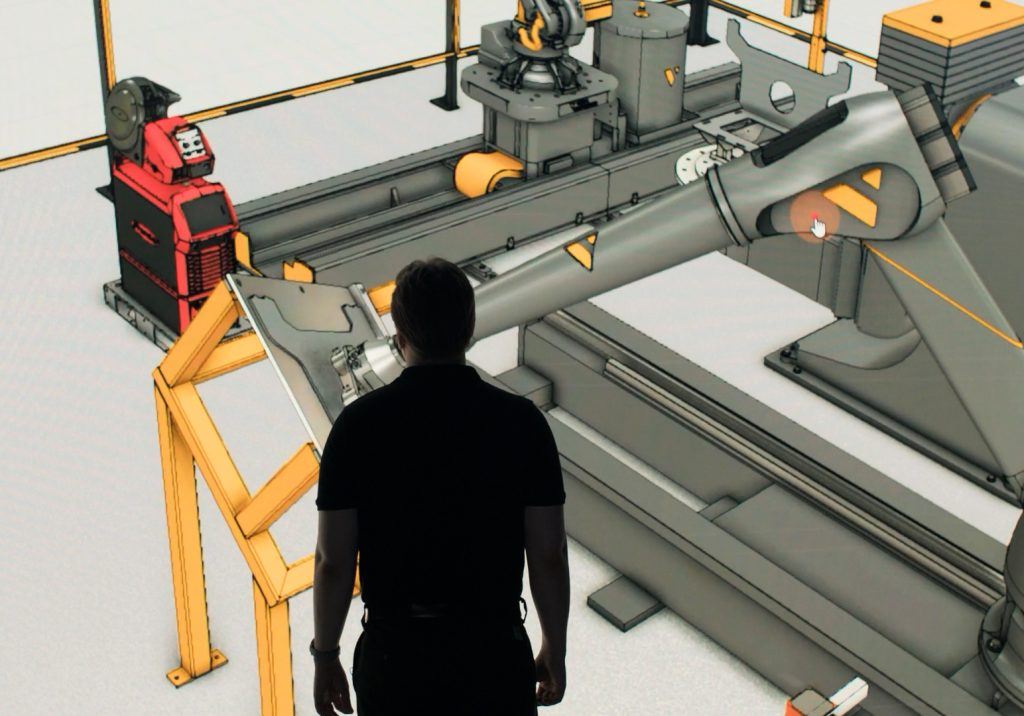

Experience manufacturing design and simulation like never before. Our other products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.

Check out our industry case studies

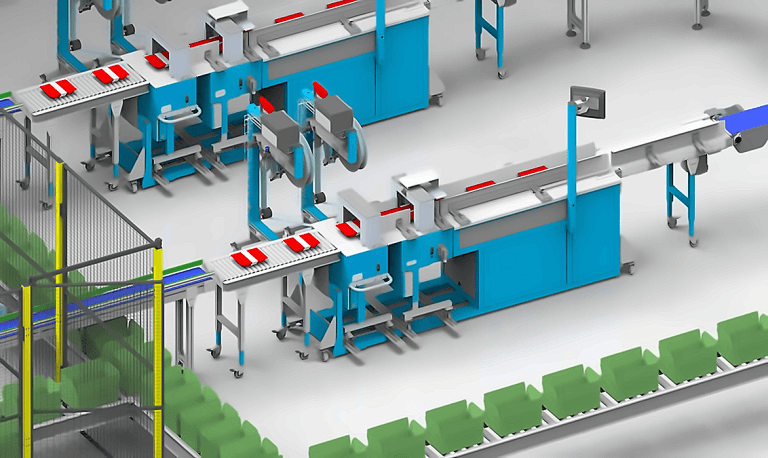

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design…

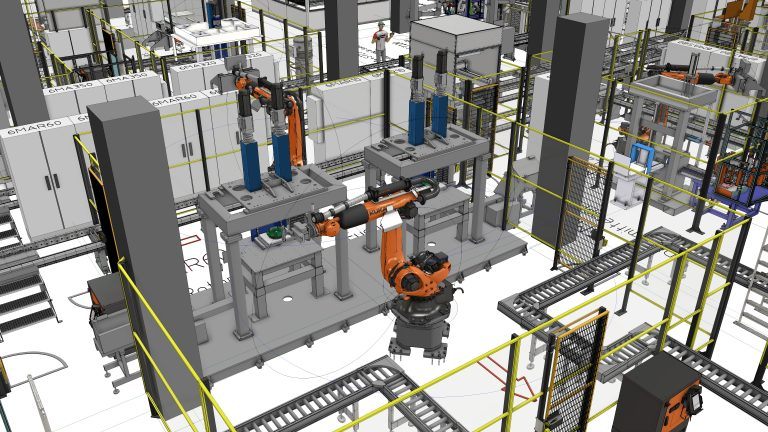

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory…

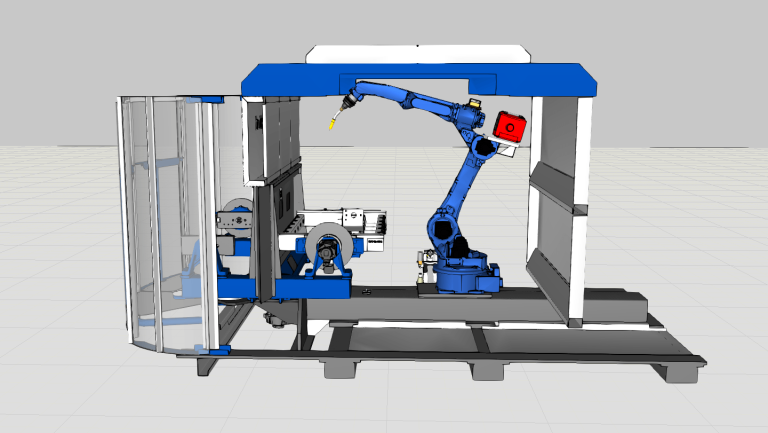

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot…