Automate 2025

Automate, held in in Detroit, Michigan, USA from May 12-15, 2025, is the largest robotics and automation event in the Americas! Visit us at booth 2650!

- Date: 12.5. - 15.5.2025

- Location: Detroit, Michigan, USA

- Keywords: automation, robotics, digitalization, AI, Material Handling

Automate 2025

We are excited of showcasing our full suite of simulation and offline programming robotic software at upcoming Automate 2025. Visit our booth 2650!

“For a company that needs to improve output, it can be daunting to change because variables seem endless,” says Graham Wloch, Director of Business Development at Visual Components. “We eliminate guesswork for our customers with our simulation software by running scenarios and identifying new processes compatible for all departments.”

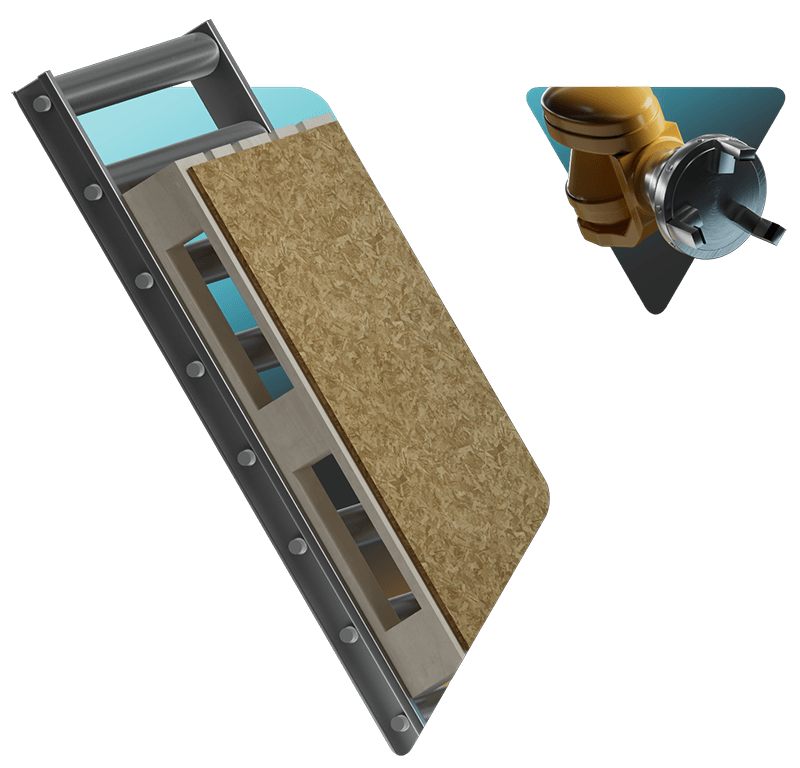

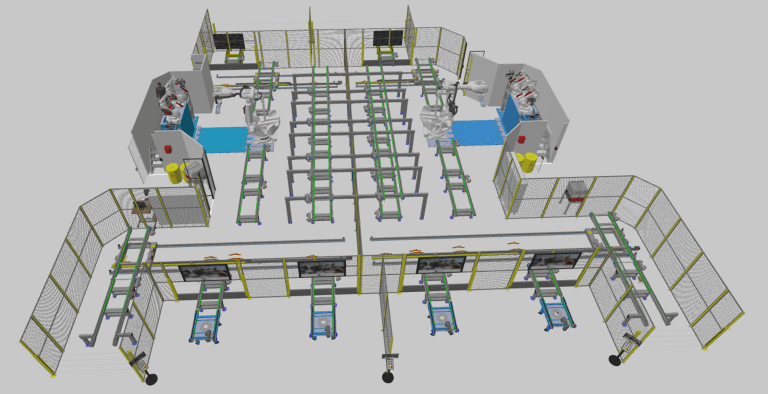

Visual Components software includes an extensive library of 3D models with over 1,600 robots, 70+ brands, and a wide range of conveyors, machines, resources, robot tools, and factory facilities. The ready-made components allow manufacturers to design, build, and simulate more efficient production lines. A feasibility analysis feature identifies and resolves production issues in the virtual environment, providing vital data for all team members.

“Our simulation goes far beyond adding robotics to meet production goals,” Wloch adds. “We examine labor allocation, space optimization, shipping functions, and any function that influences final output.”

In addition to our simulation software, we will showcase our offline programming (OLP) robotic software. Compatible with any industrial robot brand, process, or complexity, our OLP improves robot utilization rate with fast, accurate, and error-free programming. Manufacturers decrease downtime because robots can continue working on the production floor while programmers update or re-program them from anywhere. Our OLP software stores process knowledge, making it simple to reuse programs and preserve institutional information.

On Conference Stage at Automate

When: Wednesday, May 14, 2025 1:30 PM – 2:15 PM (EDT)

Where: Room 320

Speaker: Graham Wloch – Director of Business Development, Visual Components North America Inc.

Doing More with Less Through Simulation

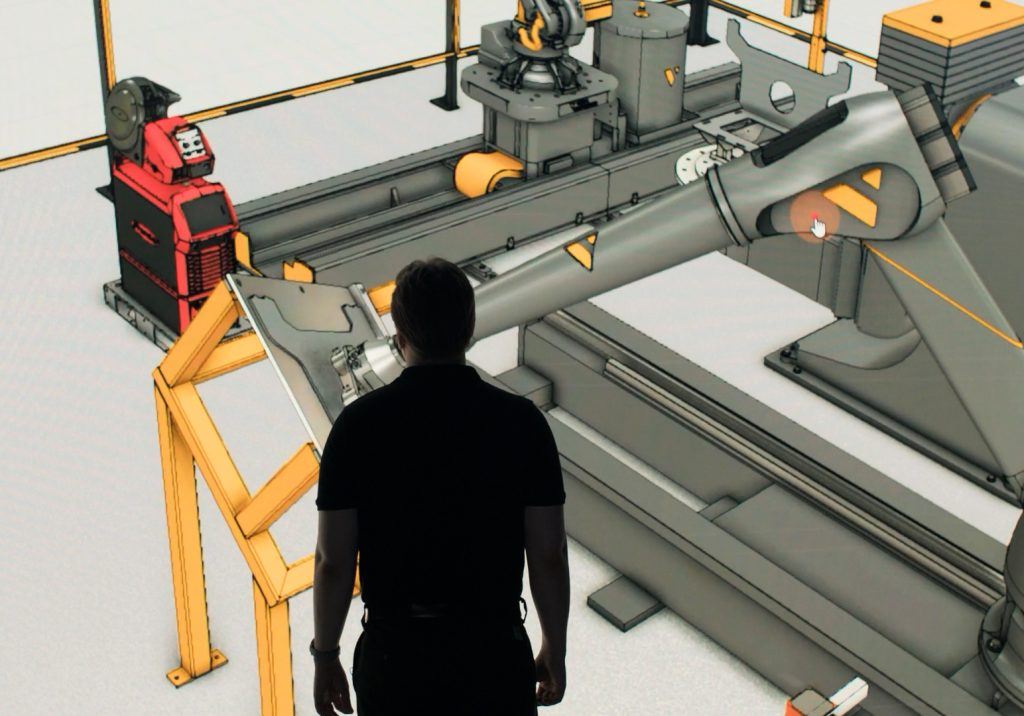

Manufacturing and its challenges are constantly changing and evolving. In the last several years those challenges have been accelerated and left manufacturers needing new tools to deal with them effectively. The same old way of doing things simply isn’t good enough anymore and new tools are needed.

Simulation allows you to visualize and better understand your manufacturing process. From capturing concepts and ideas to get everyone on the same page and to launch continuous improvement projects, simulation can give you the edge in your industry. By comparing scenarios in the simulation environment, you can use the statistics Visual Components can generate to make data driven decisions that you are genuinely confident in.

Want to automate processes but are unsure where to begin? Simulation can show you exactly what the outcome will be so you can avoid zero net gain or even worse, have unintended consequences because of a consequential decision. Automation for the sake of automation is never a good idea, but using simulation can determine the best-case scenario for the improvement of a process.

Robots, AGVs, and AMRs are often the focus of automation which makes sense. People however are just as important. With the shortage of skilled workers, having them in the right places is critical for a process to achieve maximum efficiency. Along with those highly coveted skilled workers, the interaction of all resources is essential when it comes to understanding the complete manufacturing process.

The right automation and the right people in the right places can lead to increased thruput, efficiency, reduced capital expenditure, a smaller footprint, and an increase the bottom line. Simulation lets you achieve all of these without having to disrupt your ongoing process.

Simulation is no longer a novelty, but a necessity for companies looking to use all of the tools available to them to improve processes and do more with less at the same time!

Find out the full conference agenda here.

Get your free ticket for “Automate” here

Use the unique promo code: 120123

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

Simple. Visual. Powerful. Design and validate new production solutions confidently with Visual Components’ 3D manufacturing simulation software.

Fast. Easy. Universally compatible. Create efficient, error-free robot programs with Visual Components’ robot offline programming software.

Experience manufacturing design and simulation like never before. Our other products offer various ways to showcase your simulations, including viewing them on the phone, embedding them on your website, or using immersive VR.

Check out our industry case studies

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

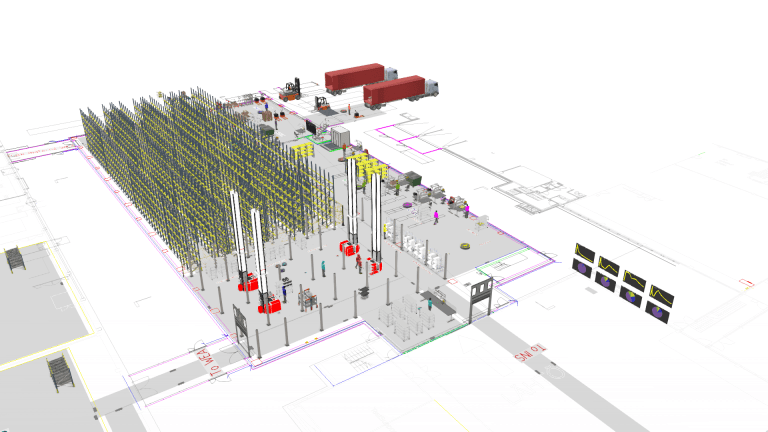

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

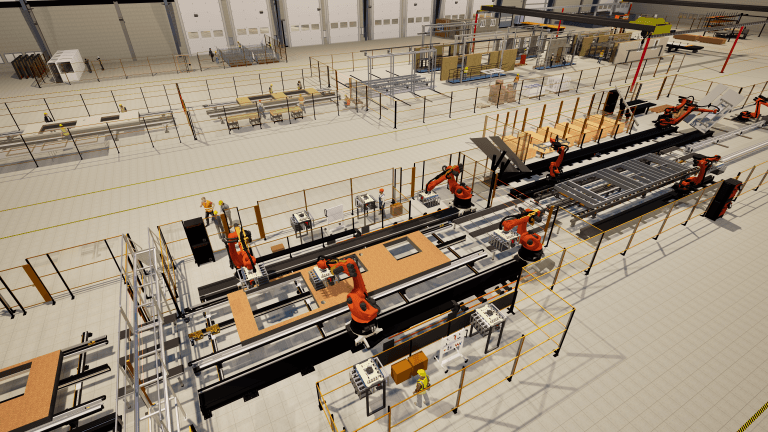

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more…