Toolcraft Case Study: The First Production Line For “Batch Size 1” In The Furniture Industry

In this case study, we’ll show you how MBFZ toolcraft GmbH used Visual Components to develop the first production line for “batch size 1” for the automated assembly of individual drawers for a manufacturer of bathroom furniture.

The typical customer of today wants individual products on the one hand, but on the other hand also wants low prices. However, these two goals seem to contradict each other: The diversity of customer wishes leads to a high variance of products and thus to increasing complexity of production. However, there is a solution – customized mass production or mass customization.

The trend towards customized mass production is not only evident in the automotive industry, where customers have long been able to choose between countless extras, but also in the furniture market. This is particularly true for bathroom furniture, which often has to be installed in a narrowly defined space and where a wide range of dimensions, colors, and surfaces are offered. Another complexity is added by the technical conditions, i.e. the number, shape, and size of the washbasins and the number and design of the siphons.

Most furniture manufacturers would be overwhelmed by the task of converting their operations or production facilities to customized mass production under their own steam. But fortunately, there are specialists for such tasks, such as the company MBFZ toolcraft GmbH from Georgensgmünd in South Germany. The company is a pioneer in advanced technologies such as individual turn-key robot solutions. MBFZ toolcraft GmbH, which has received several awards of excellence, was founded only in 1989 and now employs around 400 people. Its customers include market leaders from the semiconductor industry, aerospace, medical technology, the optical industry, special machinery as well as motorsports and automotive.

Required by the customer: Production with “batch size 1“

To meet the market requirements for customized mass production, a well-known manufacturer of bathroom furniture asked MBFZ toolcraft GmbH to develop a robot system for the automated assembly of drawers for bathroom furniture. The drawers, with or without siphon, were to be of various sizes, from the smallest drawer with 170 mm to the largest with 1450 mm.

The furniture manufacturer also demanded the production of a wide range of variants with individual material and color selection with “batch size 1”; i.e. it should be possible to produce each piece of furniture as a custom-made product if required. With modern production technology, even batch size 1 can be profitable for the manufacturer and affordable for the customer.

Before automation, assembly of the drawers was carried out manually with hand tools; the drawer frames were pressed to the floor using a pneumatic press. The new plant was designed to enable production in two shifts; it was to facilitate manual processes and automate monotonous activities.

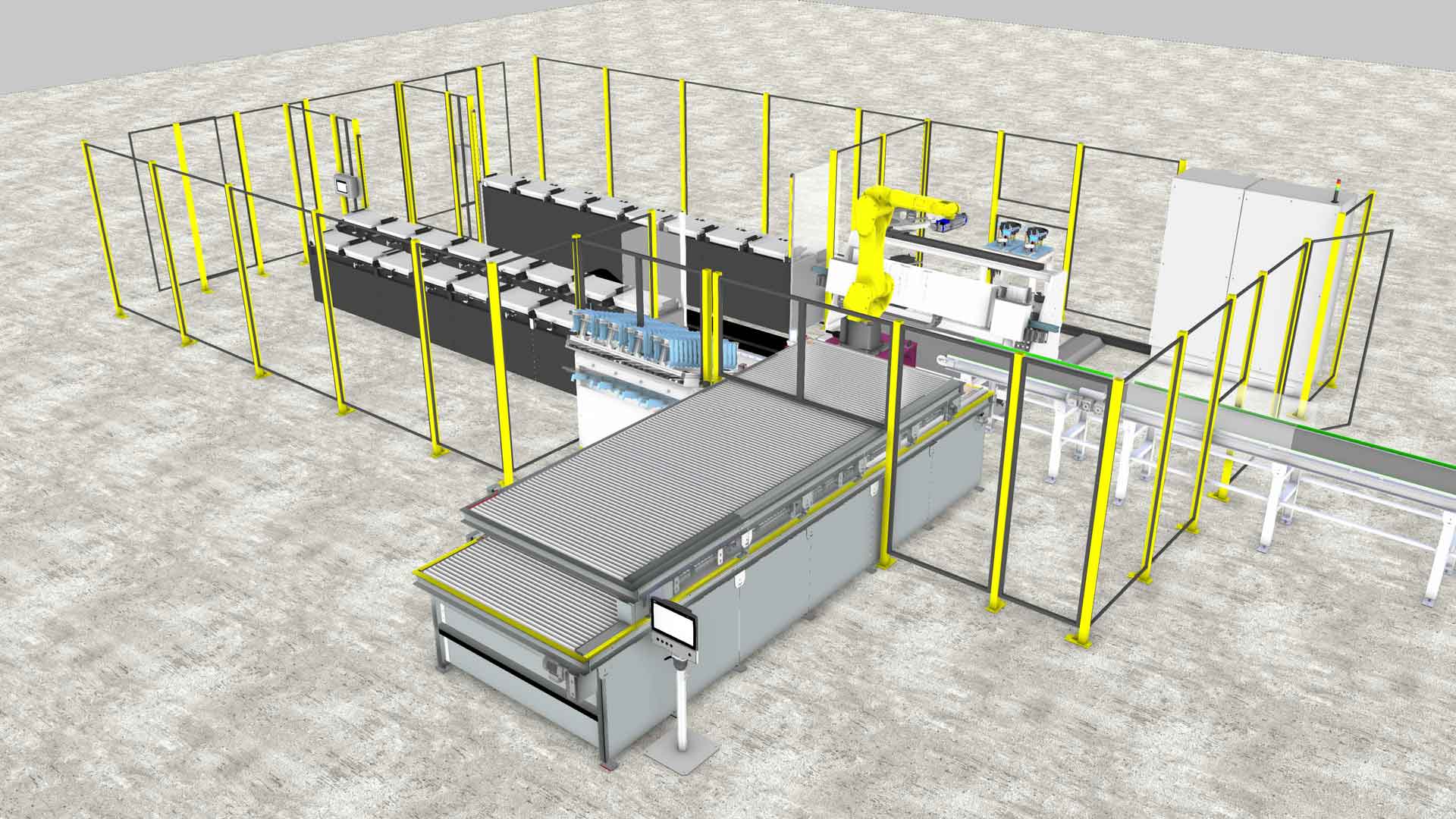

The production line was planned entirely virtually with Visual Components

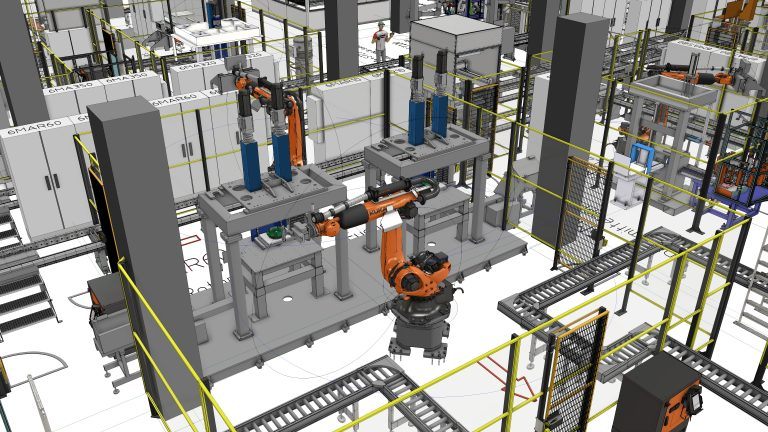

Following the customer’s request, a feasibility study and visualization were carried out in the concept phase. For this purpose, MBFZ toolcraft GmbH used the factory planning and simulation software from Visual Components. With Visual Components, the company uses an ideal system, because, with the software for 3D factory simulation from the Finnish company, Toolcraft can design, simulate, optimize, and validate customized production systems.

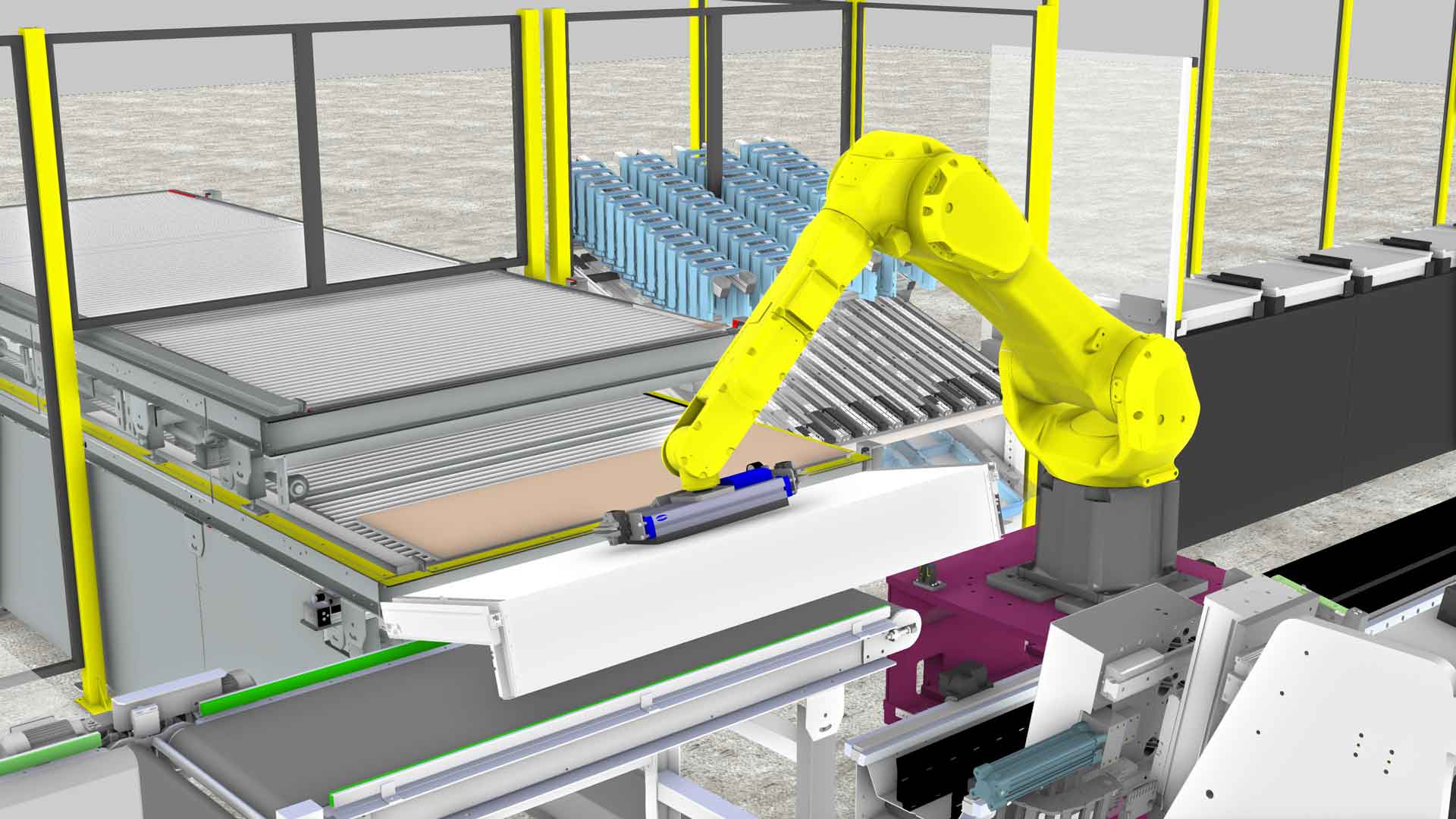

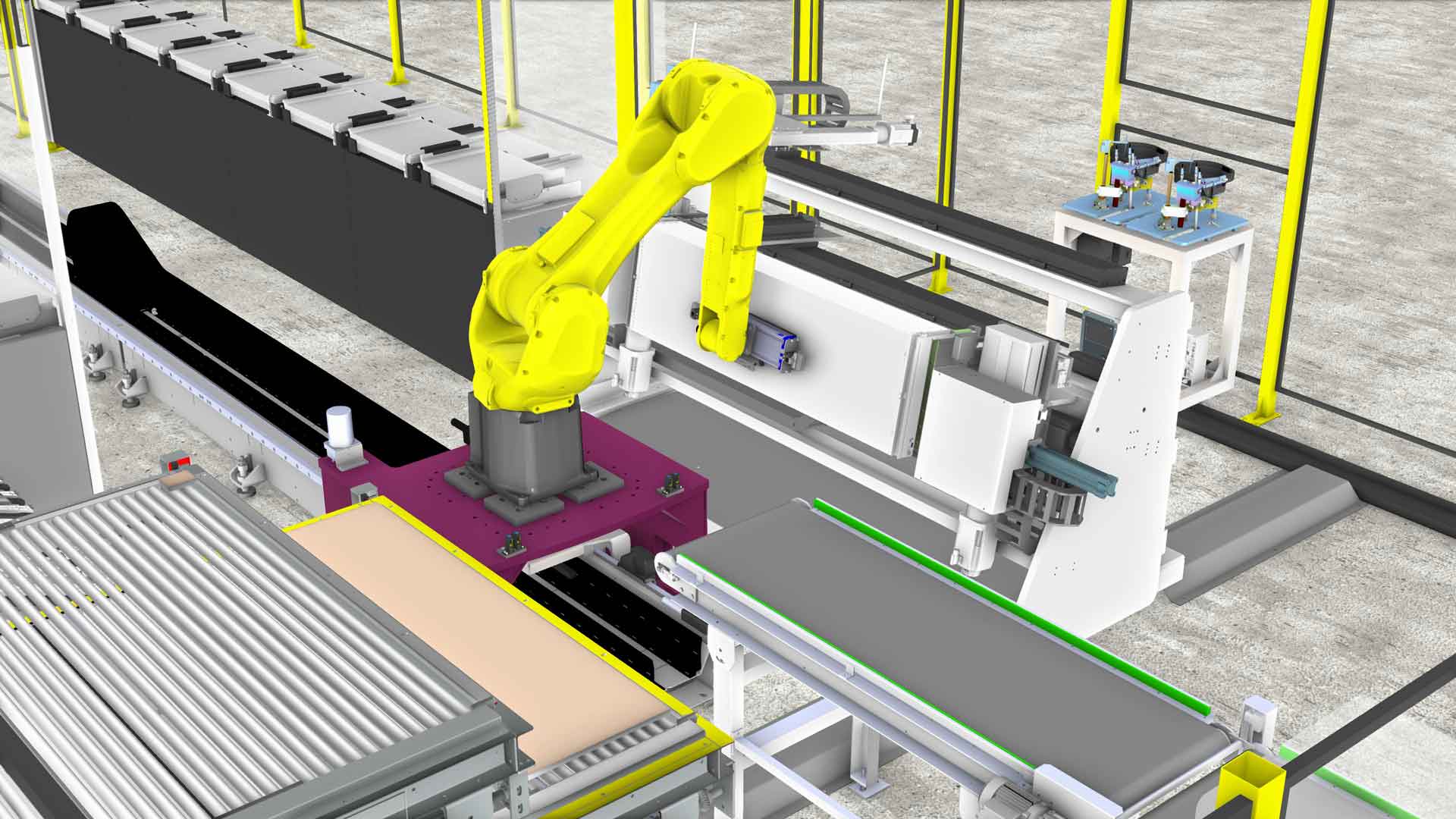

In the newly designed system, the component data are recorded and processed by a scanner after they have been placed on a conveyer belt. A robot feeds the individual components to an automatic assembly station where they are screwed or pressed together. Then the fully assembled drawers are placed on a conveyor belt by the robot and transported to a station where they are manually removed and picked or stored.

The special feature of this project: It is the first plant for a “batch size 1” production in furniture manufacturing. The planning, implementation, and construction of the plant took about a year and three months.

The library of factory components from Visual Components facilitates planning

One of the challenges was that the assembly line requires complex sensor technology and monitoring, because the components must be positioned in precise relation to each other. To ensure full flexibility, it was necessary to implement the handling of all component variants with only one flexible gripper system. Furthermore, a fully automated assembly press had to be developed and integrated into the production line.

The starting point when planning such a system is usually a 2D layout. Based on this layout, factory components such as conveyor system, assembly press, robot, and grippers are assembled to form a production line. MBFZ toolcraft GmbH used the library provided by Visual Components; if a specific machine was not available in the library, it was created from an existing CAD model and inserted into the library. Visual Components has interfaces to all major CAD systems.

Visual Components facilitates the design of the production line

Visual Components’ solutions played a key role in the successful completion of the project. First of all, the entire plant was set up and visualized virtually. The virtual model was used to ensure the basic feasibility of the concept requested by the customer.

The exact dimensions of the factory components are stored in the library from Visual Components. This made it possible to carry out very simple tests on the virtual model to determine the reach of the robot and the accessibility of all work areas. This facilitated the positioning of the assembly press, the robot, and the conveyors.

Production cycle times were optimized with Visual Components

The Visual Components’ library also contains other important attributes, such as the movement parameters of robots, which can be used to carry out exact time and movement simulations. As a result, the entire system could be optimized by determining the minimum possible cycle times on the virtual model. By doing so, the company was able to prove the economic benefit of the system to the customer.

Thanks to Visual Components, it was not only possible to determine the technical feasibility and quantify the economic benefit; the model created with Visual Components also made it much easier to illustrate the system and the production sequence to the responsible employee at the customer, the furniture manufacturer.

Visualization with Visual Components illustrates even complex systems

Bernd Krebs, Managing Director of MBFZ toolcraft GmbH, says: “We use Visual Components’ solutions in our company for all projects that require visualization and feasibility analysis”.

We use Visual Components’ solutions in our company for all projects that require visualization and feasibility analysis

Bernd Krebs, Managing Director of MBFZ toolcraft GmbH

MBFZ toolcraft GmbH particularly appreciates the fact that the process steps, even for complex systems, can be easily visualized and presented to “non-technicians”.

“Budgeting and pricing are also greatly simplified because we can set up the entire system digitally beforehand,” says Bernd Krebs. “We are also planning to use Visual Components to simulate processes in other manufacturing areas of expertise, e.g. additive manufacturing and machining, mold making and plastic injection molding as well as automated quality inspection”.

A win-win situation for all involved

As a result, MBFZ toolcraft GmbH and Visual Components have helped the bathroom furniture manufacturer to fulfill its customers’ wishes for individual yet affordable products. As a pleasant side effect, it can be noted that the production throughput could be increased while maintaining the same quality, and that many monotonous tasks are now carried out by robots – a win-win situation for all involved!

Further reading

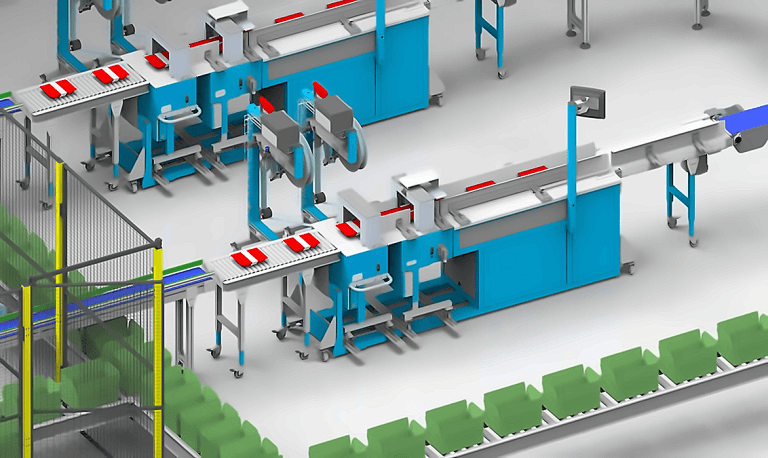

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

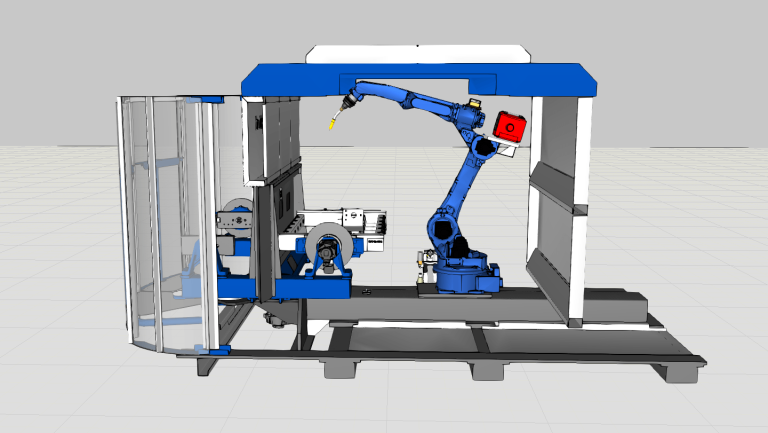

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...