Bell Helicopter Case Study: Setting the pace for the vertical lift industry

See how Bell Helicopter uses Visual Components to manufacture innovative aircraft.

Robot simulation in the aviation industry

Bell Helicopter is a Texas-based manufacturer of vertical lift aircraft. Bell has become the industry leader since its founding in 1935 and was also the first company in the world to obtain certification for a commercial helicopter.

Bell Helicopter representatives were able to see firsthand the incredible potential provided with robot simulation at the Visual Components display during the 2012 International Manufacturing Technology Show (IMTS). The ease-of-use of the software and ability to import a wide variety of model types inspired the aircraft manufacturer to try Visual Components – with impressive results.

“The support and training we have received from the Visual Components team has allowed us to come a long way in just a few years in developing advanced capabilities and implementation of automation technology into Bell Helicopter production,” says Jeffrey Nissen, Bell’s Business Development Manager – Science and Technology.

Bell has evaluated several other competing programming and simulation packages, but the adaptability, power, ease-of-use and level of support they receive from Visual Components has made the software a valuable asset for Bell.

Visual Components is perfectly suited to excel in Bell Helicopter’s design environment through its software flexibility as well as new development with Visual Components technical support.

Jeffrey Nissen, Business Development Mgr – Science and Technology, Bell Helicopter

The perfect solution for working with niche technologies

Bell’s Advanced Quality Systems Applications Laboratory is responsible for the development and implementation of automation technology focused on rotorcraft manufacturing and inspection. One use of Visual Components software is to perform application analysis as well as production programming support. So far five employees have been trained to use the software, with several more to come.

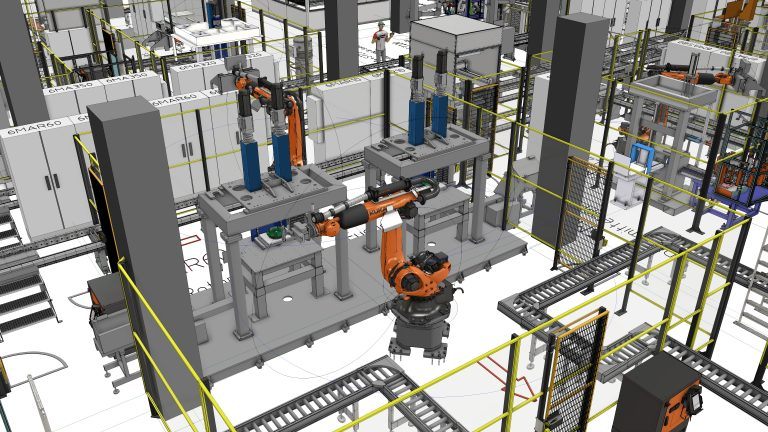

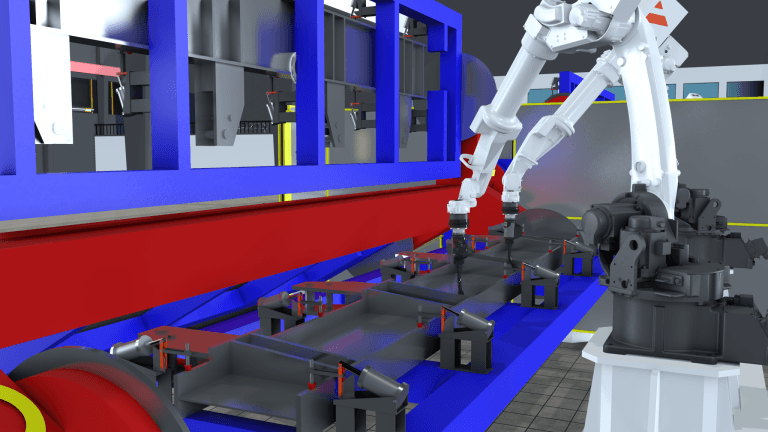

The engineers model virtual manufacturing operations to establish feasibility and demonstrate capability to Bell leadership. Bell is also using Visual Components’ advanced functionality to simulate operations such as white light scanning and automated drilling. In addition, the Python scripting capabilities of the software allows the team to rapidly create robot programs that can be immediately integrated into the lab or production floor.

Visual Components has greatly reduced the time to develop an automation solution and implement that solution into production. This reduces both the risks for failure and time to market for automation solutions.

“The aerospace industry is a collection of niche technologies,” Nissen says. “Visual Components is perfectly suited to excel in Bell Helicopter’s environment through its software flexibility as well as new development with Visual Components technical support.”

Further reading

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

NIMAK Case Study: There Would Be No Cars Without This Company

In this case study, we’ll show you how NIMAK GmbH, the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology, uses Visual...