Powered by Visual Components: The FlexLink Design Tool

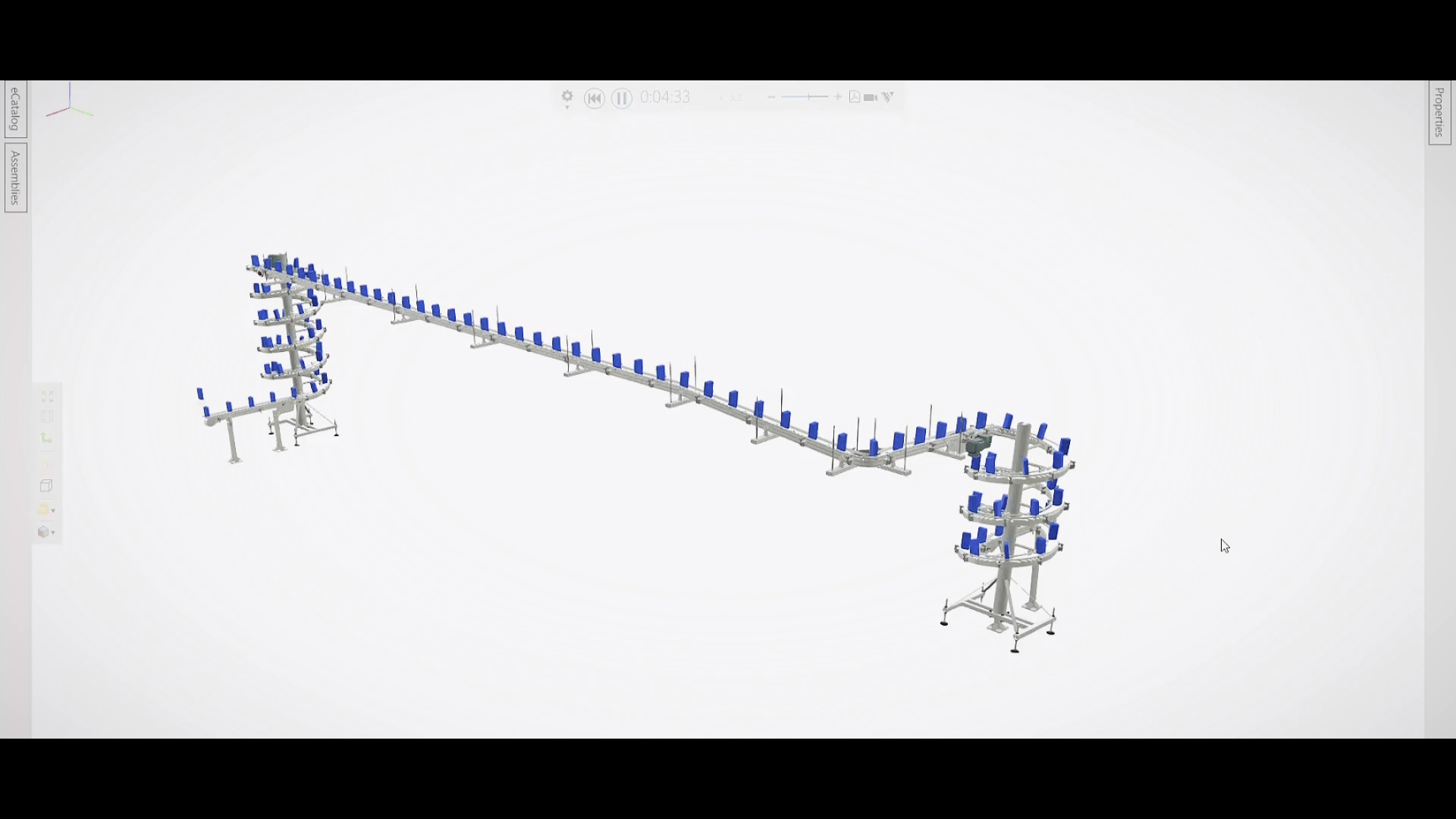

In this second video about the FlexLink – Visual Components partnership, we explore some of the key functionalities of the FlexLink Design Tool that enable it as an effective sales tool of FlexLink systems.

In our first video FlexLink Case Study: Not just a Platform, a Partnership, we learned about FlexLink’s vision for the FlexLink Design Tool, and why they chose the Visual Components 3D manufacturing simulation platform to turn this vision into a reality.

In this second video about the FlexLink/Visual Components partnership, we explore some of the key functionalities of the FlexLink Design Tool that enable it as an effective sales tool of FlexLink systems. We also hear from FlexLink’s COO why hundreds of their customers use the FlexLink Design Tool daily, and how it has positively affected not only their sales but also the customer experience.

Further reading

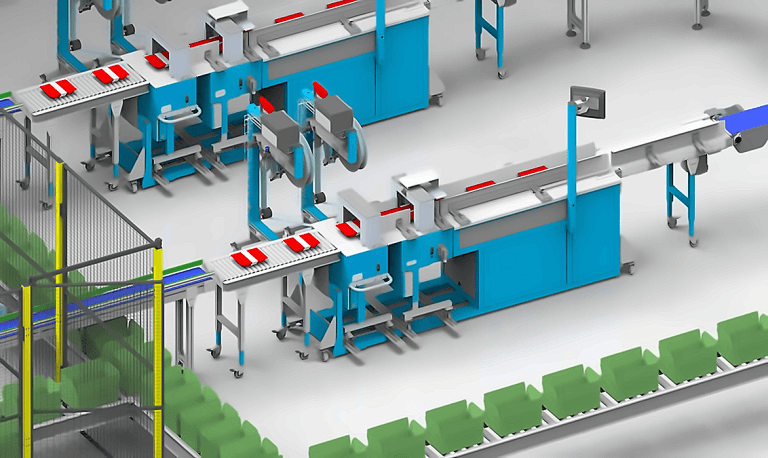

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

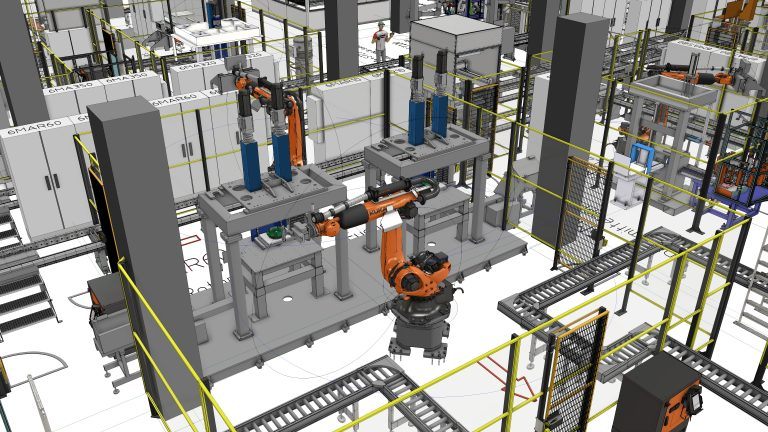

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

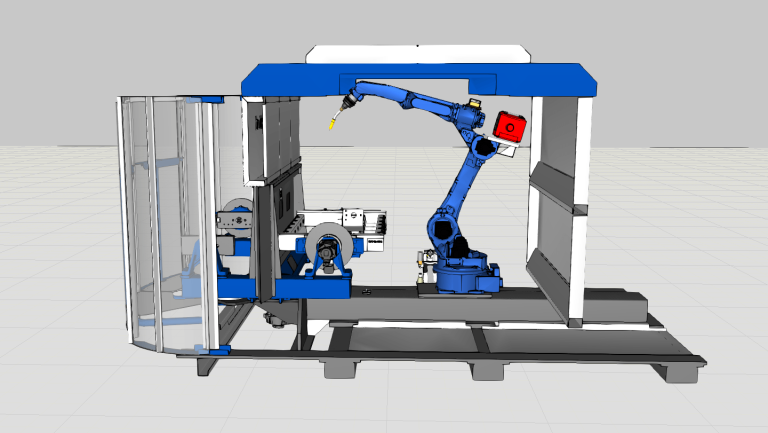

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...