Pemamek Case Study: The Birth & Evolution of PEMA WeldControl

In this case study, we’ll show you how Pemamek uses their powerful software, PEMA WeldControl, as both an offline programming and sales tool for their robotic welding solutions, and why they chose to build the software on the Visual Components 3D manufacturing simulation platform.

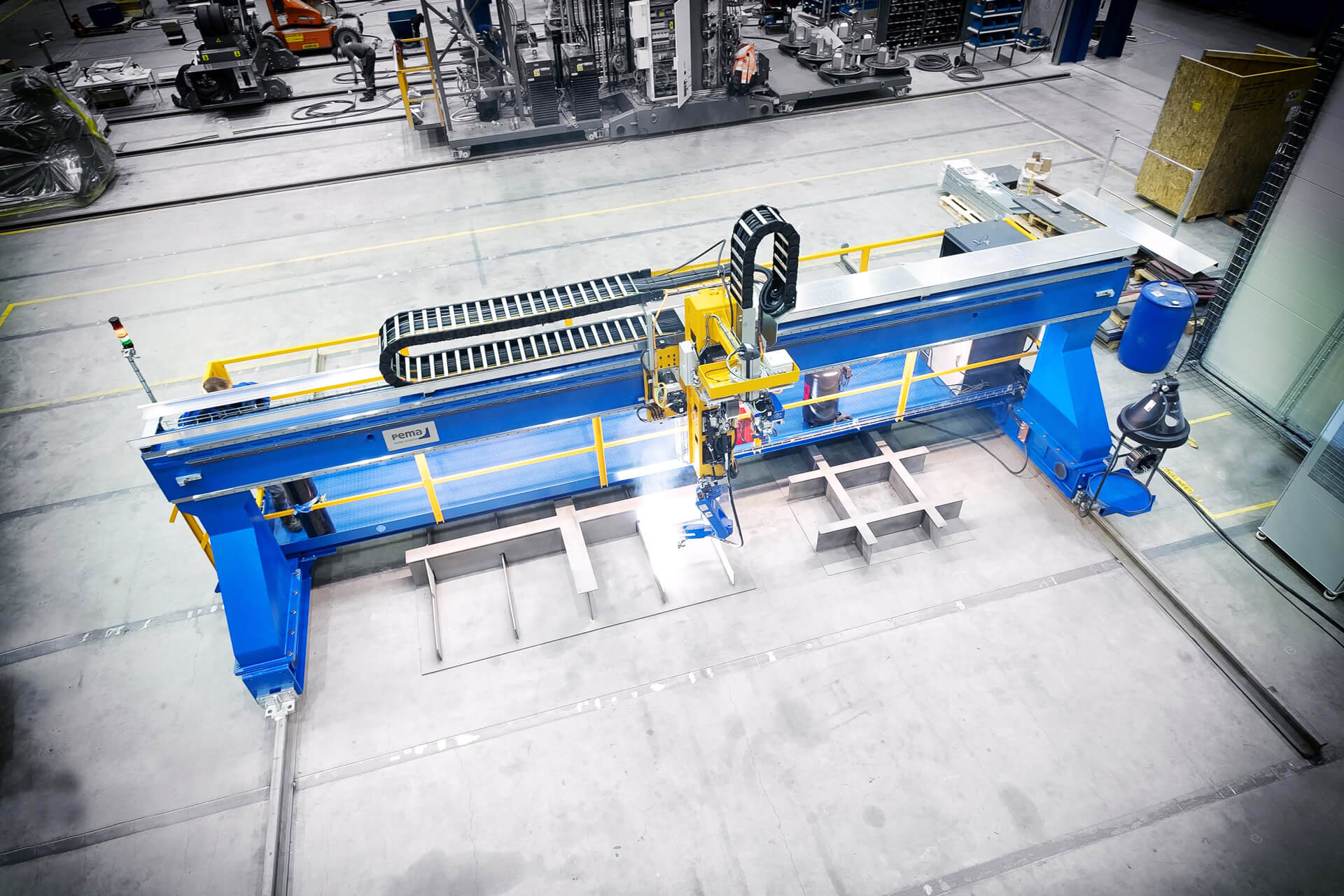

Pemamek is a global supplier of welding and production automation solutions. Founded and headquartered in Loimaa, Finland in 1970, Pemamek today employs 230 personnel at its Finnish headquarters and has sales offices in the USA, Russia, Brazil and Poland. The company has delivered more than 15,000 automated welding and production solutions to customers in over 50 countries.

In addition to custom and turnkey hardware solutions, Pemamek also develops and offers its own software, PEMA WeldControl, for the control and programming of PEMA robot welding solutions.

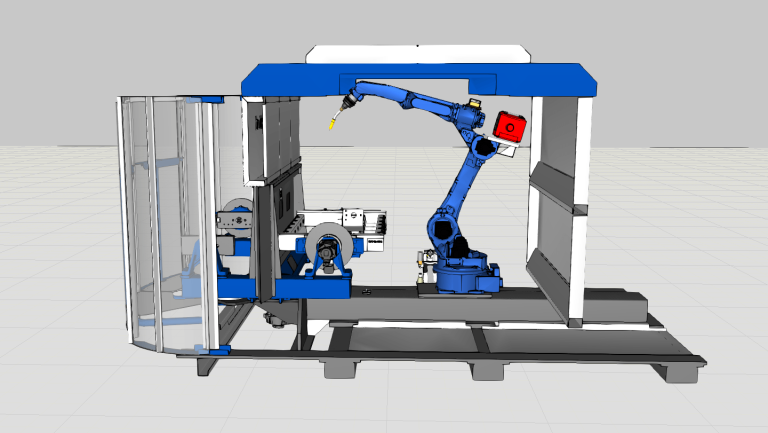

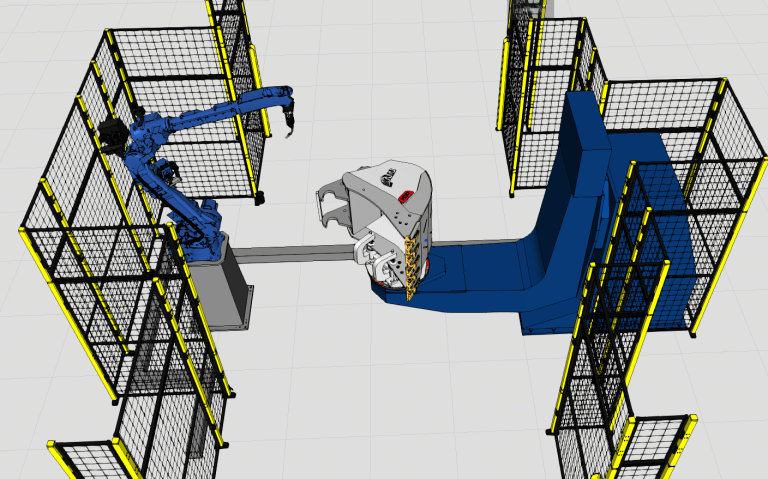

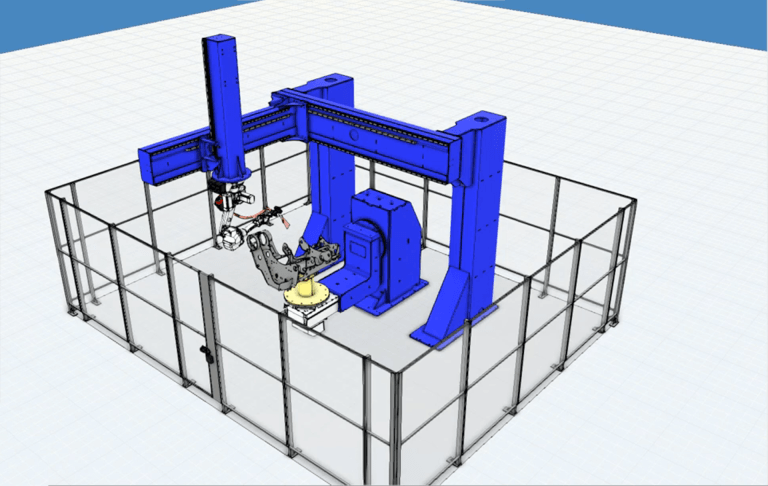

In this case study, we’ll show you how Pemamek uses their powerful software, PEMA WeldControl, as both an offline programming and sales tool for their robotic welding solutions, and why they chose to build the software on the Visual Components 3D manufacturing simulation platform.

The Birth of PEMA WeldControl

Prior to developing PEMA WeldControl, Pemamek used other commercial simulation software for both their own purposes as well as to offer their customers for offline programming (OLP) of their robotic solutions. However, as their competition became more global, and competitors began offering turnkey hardware/software solutions, Pemamek realized this put them at a disadvantage.

“We are in a highly competitive market, and it’s essential that we offer our own OLP tool in order to be competitive for projects,” said Teemu Rusi, PEMA Robotics Team Leader.

The company made the decision to develop their own OLP software, which they called PEMA WeldControl.

“The origin of our WeldControl software is actually in the shipbuilding industry,” said Teemu. “We developed a unique solution for camera vision-based programming for welding ship panel components. We wanted these features to be available in general fabrication as well, so we developed our own offline programming software with Visual Components as the 3D engine for it.”

WeldControl quickly gained traction and importance in PEMA for both its use as a sales tool and OLP solution that they could offer customers. The PEMA WeldControl product family now consists of 5 main products: WeldControl 100, 200, 300, 500, and 700. WeldControl 200 is Pemamek’s robotic welding solution for shipbuilding and WeldControl 300 is designed for heavy industry, both of which are built on the Visual Components platform.

Selecting a platform

In selecting a platform on which to build WeldControl, ease of use was one of Pemamek’s top criteria, from both a development and end-user perspective.

“The Visual Components platform offers good interfaces that allow us to develop the functions and features that we need and that our customers want,” said Teemu. “We’re constantly working to improve the capabilities and usability of WeldControl for our end users and the Visual Components platform gives us the flexibility to do this.”

Lasse Lahtinen, Product Manager for PEMA WeldControl agrees.

“Working with the Visual Components platform is very easy,” said Lasse. “The user interface is easy to understand and there are already many tools and features available for our purposes. The open programming interface and support for common programming languages make it easy for us to further customize and develop our applications.”

“Also, the component libraries in the public eCatalog, especially the robot models, are very comprehensive.”

Simulation performance was also an important criterion in selecting a platform, as some customer applications for WeldControl can be quite intensive. “Importantly for us,” said Teemu, “The 64-bit 3D engine has proven to be stable even in very complex configurations.”

Working with the Visual Components platform is very easy. The user interface is easy to understand and there are already many tools and features available for our purposes. The open programming interface and support for common programming languages make it easy for us to further customize and develop our applications.

Lasse Lahtinen, Product Manager for PEMA WeldControl

Simulation that drives sales of new systems while improving customer productivity

While the main purpose for Pemamek to develop PEMA WeldControl was to accelerate the commissioning and improve the productivity of their robot welding solutions, it quickly became their best sales tool.

“The biggest leap forward has come from the pre-sales phase, where Visual Components is a superior tool for convincing the customer how our robot welding solutions will meet their needs, such as fitting the layout, capacity estimations, and meeting production requirements,” said Teemu. “We can utilize our WeldControl offline tools for creating pre-sales material like simulations for the customer workpieces.”

The biggest leap forward has come from the pre-sales phase, where Visual Components is a superior tool for convincing the customer how our robot welding solutions will meet their needs, such as fitting the layout, capacity estimations, and meeting production requirements.

Teemu Rusi, PEMA Robotics Team Leader

“With WeldControl and Visual Components, we can quickly create sales materials such as 2D drawings and 3D simulations, which were previously very time-consuming tasks. Today, we regularly create these materials prior to the first customer meeting since it’s so fast and easy. It’s always good to visualize with them the planned layout or some certain described functions.”

With WeldControl and Visual Components, we can quickly create sales materials such as 2D drawings and 3D simulations, which were previously very time-consuming tasks.

Teemu Rusi, PEMA Robotics Team Leader

For Pemamek’s customers, the software is an important if not required component of their investment in robot welding systems.

“WeldControl software is a critical element in all robotized welding systems that we offer,” said Lasse. “It offers the offline programming and the system managing tool to the customer.”

“Our robotized systems for shipyards can’t be delivered without it. Our machinery customers don’t require it, but it’s strongly recommended to improve productivity.”

While not all Pemamek’s customers think OLP software is a necessary tool when exploring robot welding solutions, especially if it’s their first system, most of them quickly realize its value when introduced to WeldControl in the pre-sales phase.

“Our benefit in the sales is that our software is fully optimized with our hardware: we don´t need to compromise anything and we are also ready to implement special customer needs if needed,” said Lasse. “I believe that the total solution provided by Pemamek is the key factor in sales.”

It’s also during this phase when Pemamek’s customers see how easy WeldControl is to use.

“Many of our customers are able to have their welders and fitters perform the robot programming after a short basic training,” said Lasse. “This leads to a fast return on investment on the whole solution when the robot starts production right after the delivery.”

“It’s easy to use for individuals of all kinds of backgrounds. The software is visual and straight forward.”

A Roadmap for the Future

While Pemamek’s partnership with Visual Components started several years ago, the journey is only just beginning, and both companies are looking forward to what’s ahead. The key to the success of this partnership has been the smooth collaboration between the product development teams of Pemamek and Visual Components.

“Our experience from working with Visual Components has been very positive,” said Teemu. “They’re responsive to our needs and we know a lot of people inside the company.”

“The co-operation between Pemamek and Visual Components has been smooth and easy, and the communication is open,” added Lasse.

Looking ahead, Pemamek views PEMA WeldControl as an essential part of their overall product portfolio and plans to continue the development of the WeldControl product family.

“WeldControl shall be developed further,” said Lasse. “We have a roadmap for the years ahead, and we’ll be relying on Visual Components to further improve the capabilities and functionalities of the platform to help us to develop the software. I’m confident that our relationship with Visual Components will continue for a long time.”

Teemu agrees. “Visual Components is a superior tool that has enabled us to create user-friendly and fast tools to meet our customers’ demands. We look forward to continuing our partnership for years to come.”

Visual Components is a superior tool that has enabled us to create user-friendly and fast tools to meet our customers’ demands. We look forward to continuing our partnership for years to come.

Teemu Rusi, PEMA Robotics Team Leader

Further reading

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...

Combatting the welder shortage: how AMI Attachments enhances production efficiency with Visual Components OLP

AMI Attachments, a leading North American manufacturer of heavy equipment attachments, sought to improve product throughput and meet evolving market demands while navigating a welder shortage. By implementing Visual Components...

Ponsse is driving forest machine innovation and improving productivity with Visual Components Robotics OLP

Ponsse Plc., a global leader in forest machine manufacturing, has transformed its production process by leveraging Visual Components Robotics OLP.