NIMAK Case Study: There Would Be No Cars Without This Company

In this case study, we’ll show you how NIMAK GmbH, the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology, uses Visual Components to improve marketing and sales and stand out from the competition to win the trust of customers.

It is really astonishing: a company is instrumental in the production of more than 70 % of cars in Germany – yet hardly anyone knows its name. The reason: a finished car does not show any of its “products”, and yet they hold everything together safely and reliably – thanks to the welding spots!

NIMAK – The inventor of the robot welding gun

NIMAK GmbH, based in Rhineland-Palatinate, Germany is the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology. In addition to welding guns and equipment for spot welding and roller seam welding, the company also manufactures machines for projection welding. In projection welding the weld is created by means of raised sections, or projections, on one or both of the workpieces to be joined. Only these projections form electrical contacts. During the current flow, the projection partially melts and joins with the other component. This allows, for example, screw nuts to be welded to sheet metal.

NIMAK also offers high-performance equipment for automated gluing. Today, more and more adhesive bonds are being used in the industry. They offer completely new possibilities, especially in lightweight structures, because different types of materials can be reliably joined.

Engineering of plant layouts with Visual Components

NIMAK GmbH employs approximately 430 people worldwide. Its customers operate in the automotive, consumer goods, aerospace, and metal processing industries. The technical sales department in the Automation division is responsible for responding to customer enquiries, developing equipment concepts together with the design department and preparing detailed and compelling proposals for the customers.

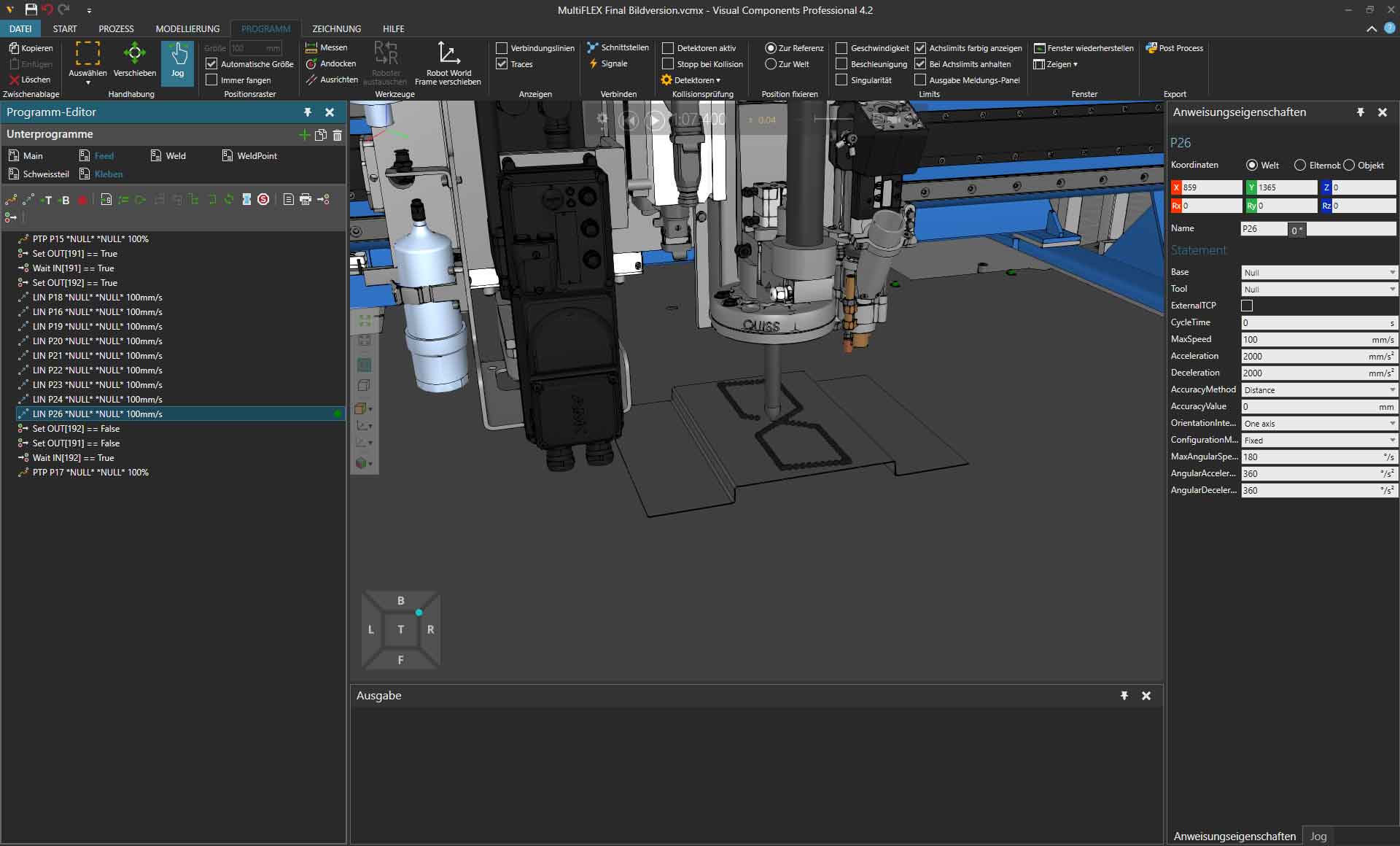

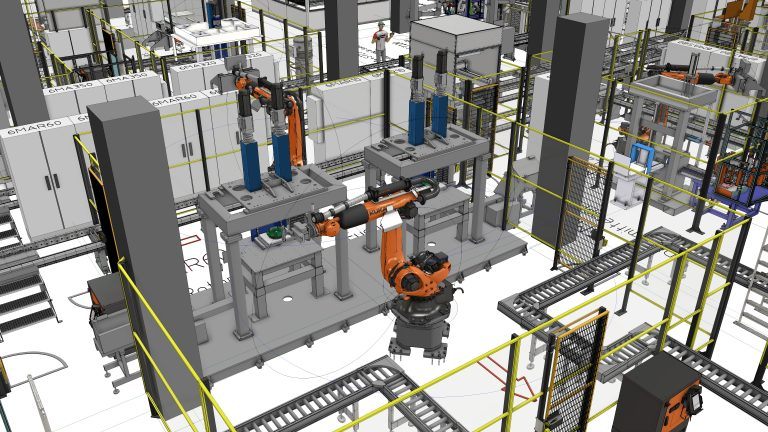

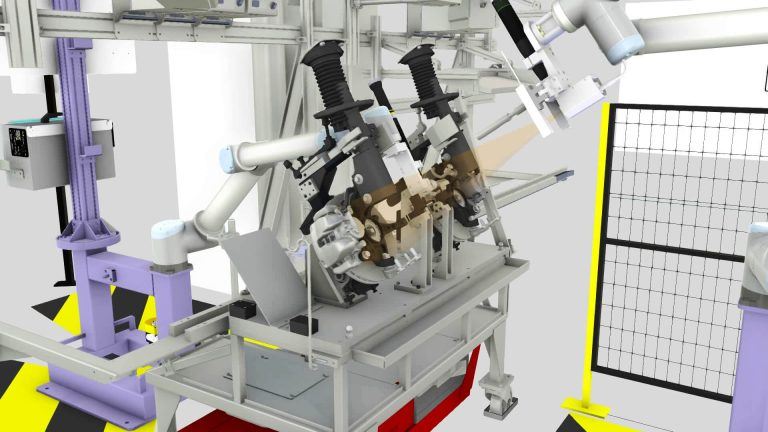

The software of the Finnish solution provider Visual Components is used for these diverse tasks. With this solution for 3D factory planning and simulation, complete manufacturing systems can be designed and optimized; offline programming of robots can also be done. The software simulates the entire manufacturing process, from stand-alone machines to complex integrated systems. Thanks to the simulation, production processes can be optimized, e.g. cycle times can be determined and minimized, and questions such as accessibility by robots and collision avoidance can be resolved.

3D simulation helps NIMAK to stand out from its competitors

Michael Hintz is working in NIMAK’s technical sales department: “I use Visual Components software every day for the development of concepts for automation systems. Our customers thus obtain a highly detailed concept in 3D in short time, which they can then show to their management.” In this way the sales of equipment can be sped up because 3D simulation of production equipment helps to create more convincing offers, to stand out from the competition and to win the trust of customers.

I use Visual Components software every day for the development of concepts for automation systems. Our customers thus obtain a highly detailed concept in 3D in short time, which they can then show to their management.

Michael Hintz, NIMAK Technical Sales Department

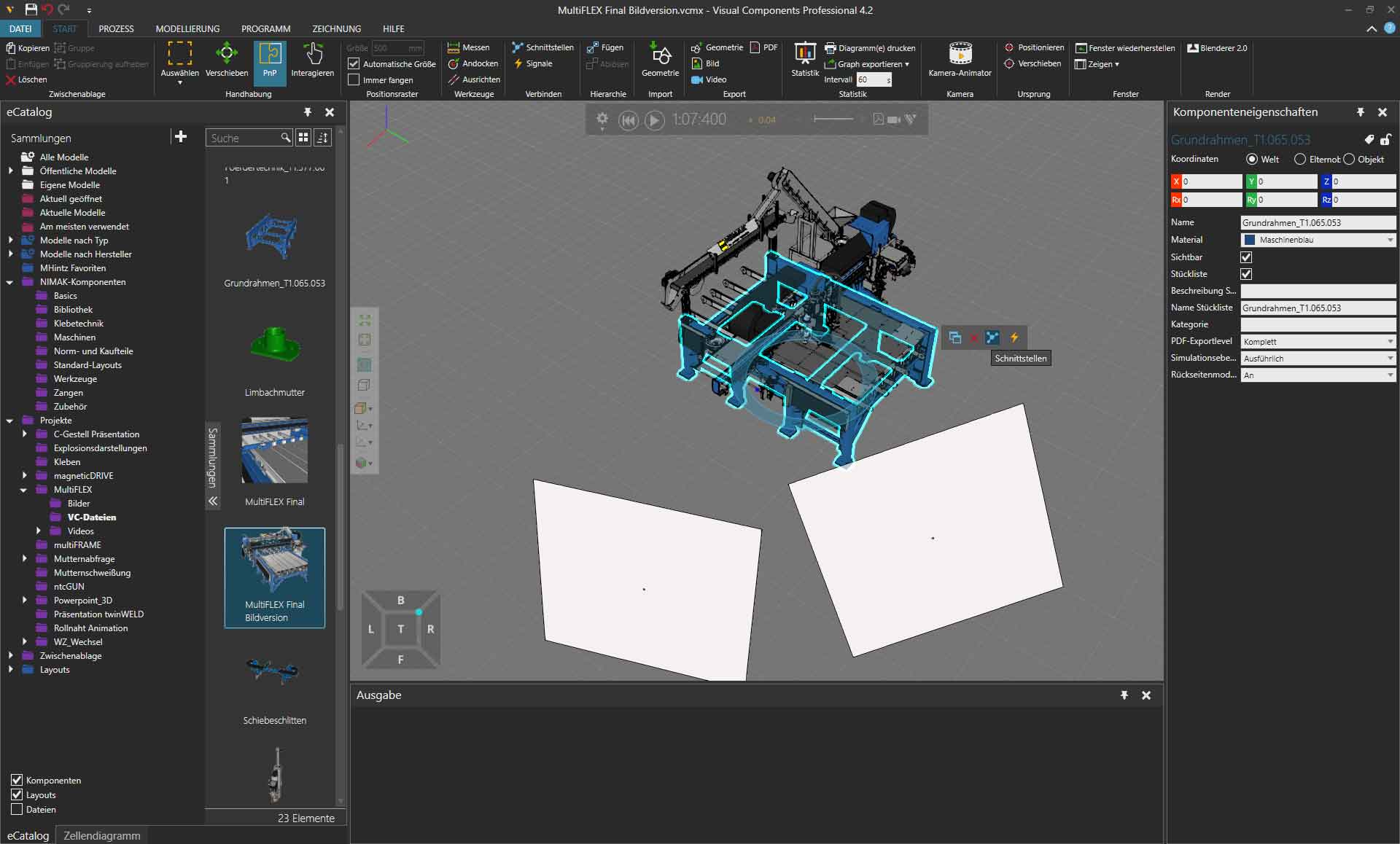

Usually, the starting point is an existing CAD model of the machine, which is imported into Visual Components via its CAD interface. This static model is then converted into a simulation-ready system using the modelling feature of Visual Components Professional. If additional factory components such as robots, barriers or conveyors are needed for larger plants, these can be easily inserted into the model from the extensive ecatalog of intelligent factory components supplied with Visual Components software.

Creating compelling marketing videos with Visual Components

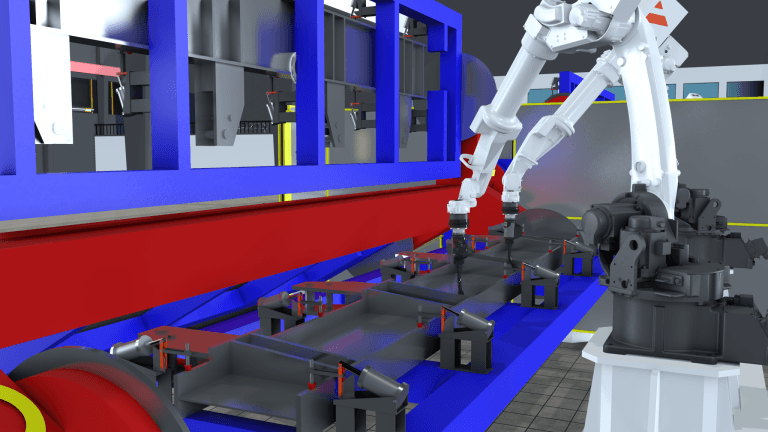

Another interesting application of Visual Components is the creation of a promotional video for the NIMAK multiFLEX, one of the most flexible machines for processing flat sheet metal. This coordinate machine can be used for projection welding, spot welding and gluing, but also for other processes such as punching, signing, plasmatizing or laser cutting. Sliding carriages allow up to six different processes to be carried out on this machine. Even the feeding of standard parts such as weld nuts or punch rivets is no problem.

Michael Hintz explains: “The aim of the project was to create a short promotional video showing the many possible features. But the machine was already in use at the customer’s premises and was no longer available for real footage. In addition, we wanted to show all possible add-ons, even those that were not actually installed on the machine in question.”

Here again, an existing CAD model of the machine was imported into Visual Components and then converted into a simulation-ready system. Mr. Hintz talks about his experiences: “It wasn’t easy at the beginning, but a Visual Components consultant, who had also carried out a training course at our company, helped me a lot here.”

The expenses for a marketing agency – we can save those now

The effort was definitely worth it: “In the past, we would have hired a marketing agency for such a video. The time and costs required for this are much higher compared to the flexibility and savings that Visual Components provides us. Once the video is created, we can adapt it at any time and without much effort. We can also integrate the machine into larger automation systems.”

NIMAK’s sales department benefits significantly from the Visual Components software. Mr. Hintz describes the advantages of the solution: “Thanks to Visual Components, we are able to create a video of almost any machine or system to describe its setup and functionality. In keeping with the proverb “A picture is worth a thousand words”, we can thus present the customer with a much clearer vision of our ideas.”

Use of Visual Components for advanced analysis and simulation

Mr. Hintz also has clear plans for the future applications of the software: “At present, we mainly use Visual Components to improve the quality of our quotations by creating 3D images and videos of machines and equipment. We have also performed cycle time analyses with great success. For the future we plan to use the numerous other possibilities offered by Visual Components, especially for analyses and simulations in the early phases of quotation.”

For the future we plan to use the numerous other possibilities offered by Visual Components, especially for analyses and simulations in the early phases of quotation.”

Michael Hintz, NIMAK Technical Sales Department

However, improving marketing and sales will remain a key focus, because NIMAK GmbH intends to further expand its strong presence in the automotive and domestic appliances segments. Even if you cannot see – and still should not see – the welding spots and seams on the finished products.

Further reading

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

How FiRAC helped automate manual sub assembly processes in PSA Group’s plant

In this case study, we’ll show you how FiRAC, a company of Groupe SNEF that specializes in the design and integration of robotics and automation used Visual Components simulation to...