Kaufman Case Study

See how Kaufman is using Visual Components to shorten their sales cycles, improve accuracy of estimates, and implement their solutions more efficiently.

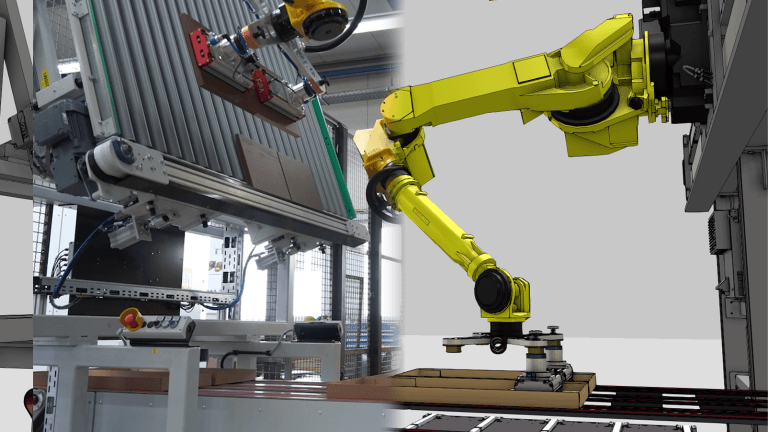

Kaufman Engineered Systems has been at the forefront of complete line automation for over 70 years. Hundreds of successful companies have chosen them for their single-source convenience, responsive service, and unmatched machine performance. Kaufman has become an international leader in the fields of robotic palletization, stretch wrap systems, conveyor systems, and custom engineered solutions. With a full staff of electrical, mechanical, and robotic engineers to design and install the machines that meet their clients’ specific needs, they are a full service provider of manufacturing line automation solutions.

Standing out in a competitive environment

Enabling change and improvement in any business is a challenge, and one that Kaufman faced with each project they took on. Being able to provide an accurate demonstration of proposed solutions to clients in the manufacturing space was a time consuming but very necessary endeavor in the sales process to get prospects and returning customers on board with proposed projects. Consulting and automation integration in the manufacturing space has become a very competitive environment, and in spite of a long track record of success, the Kaufman team was looking for ways to continue to differentiate their offerings, to stand out in a crowded landscape.

Optimizing the sales process

In late 2015, representatives from Kaufman encountered Visual Components at a tradeshow for the very first time. After viewing a demonstration of the 3D simulation capabilities, their team was enthusiastic. The ability to quickly design and deploy product line simulations during the sales process was seen as revolutionary to their somewhat lengthy sales process. The Visual Components functions and features across a spectrum of manufacturing disciplines meant that pre-sales simulation accuracy would improve and the actual implementation timeframes on projects would be faster and reduce time to full solution delivery.

The order was placed and the implementation happened quickly. The results were profound.

By reducing demonstration timeframes from 4 weeks of prep to less than a week, Kaufman dramatically reduced their sales cycle timeframe

The robust simulation capability helped eliminate the time and expense associated with setting up a sample manufacturing cell as a proof of concept. With an easy to utilize platform, sales reps were able to work with the Visual Components products on their own, reducing the need for more engineers to be involved in the sales process itself, further reducing the cost of sales for the organization.

Achieving efficiency throughout project development

With the implementation team actively working with Visual Components solutions, Kaufman saw further efficiency gains. The initial work done by the sales team and approved by the client would push directly to the project team. By taking advantage of the functions within the Visual Components platform, the engineers were able to program a wide variety of simulation applications , eliminating the need to continue using outdated methods that extended project completion time.

Improving win ratio and profitability

Kaufman Engineered Systems is now in an improved market position. Their sales process is faster, their presentation capability and professionalism had increased dramatically, and there was a greater efficiency with their solution implementation capability. Being able to respond more quickly and accurately to sales requests has enabled Kaufman to be the clear leader in the early engagement stage of the sales process, improving their win ratio and the profitability of the projects they take on.

Further reading

Packaging perfection: navigating variations in furniture packaging with Visual Components

The furniture industry has shifted from handcrafted pieces to mass-produced, self-assembly models made from materials like MDF or chipboard. This change has complicated packaging due to the need for high-volume...

3D packaging simulation success stories with DHL

See how DHL, the world’s largest logistics company uses Visual Components manufacturing simulation to power the adoption of automation in the age of accelerated digitalization.

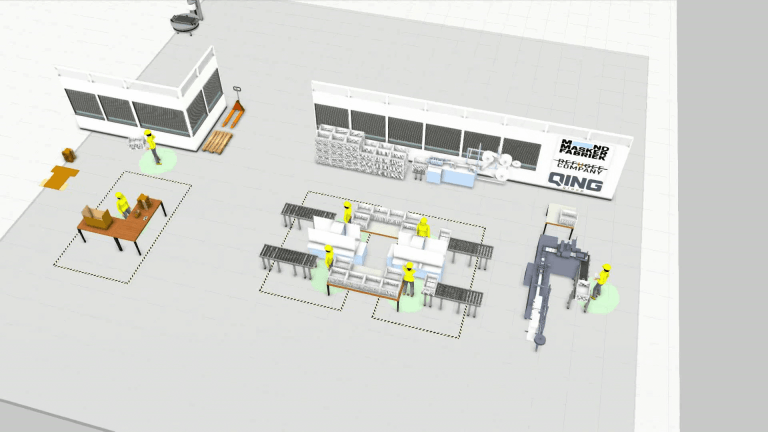

QING Case Study: Using 3D Simulation Technology to Set up a Face Mask Factory During the COVID-19 Pandemic

In this case study, we’ll examine how QING used 3D manufacturing simulation to set up a fully functional face mask factory in the Netherlands within just a few weeks to...