JOT Automation Case Study

How JOT Automation radically improved the efficiency of their sales process

A drastic improvement in sales process efficiency and flexibility

Visual Components solutions have provided great value for companies in various industries. One of these companies is JOT Automation, a leading supplier of production and test solutions for the electronics, telecom, automotive, aerospace and advanced life science industries. We interviewed Kyösti Soini, Director, Electronics Business Line at JOT Automation, to get his view on the collaboration.

JOT Automation found that using Visual Components radically improved the efficiency of their sales process.

“Our sales people used to be dependent on illustrations made with a CAD software,” Kyösti Soini says.

“What made this problematic was that when the sales person out on the field needed to make adjustments to the illustrations or when they needed entirely new ones, there was no fast way of doing it. They had to contact an engineer to get these materials. This wasn’t as efficient as we would have liked.”

The Visual Components tool makes sales meetings much more effective with a quick way to visualize solutions. Definitely a boost for business.

Kyösti Soini, Director, Electronics Business Line, JOT Automation Ltd.

Arming sales staff with easy-to-use simulation tools

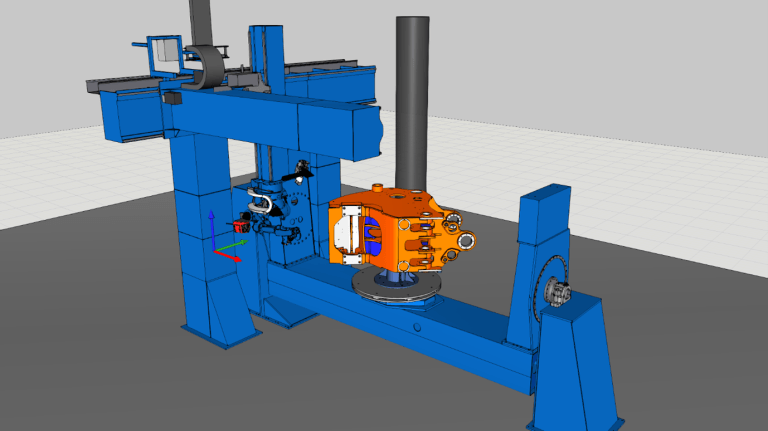

Today sales people use Visual Components to put together the simulation models they need.

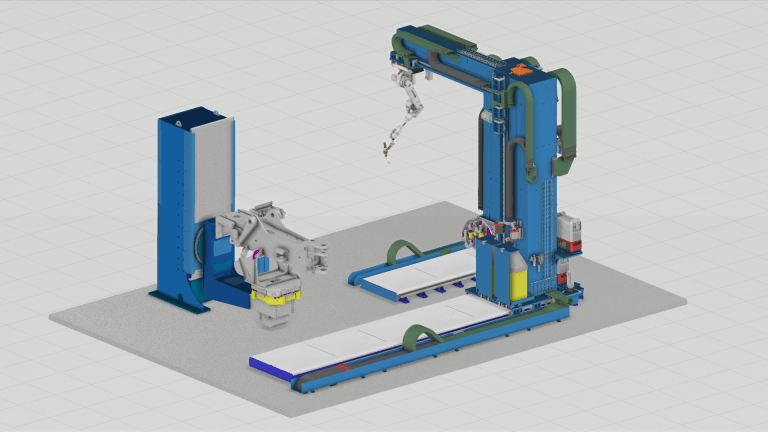

“Our sales people can do most steps themselves now. They have access to the Visual Components component library and they can pick and choose what they need really easily. Basically, after they have a meeting with the client and have figured out the needed features, they can quickly choose the right components and set up a working layout,” says Kyösti Soini.

“Another upside is that the light simulation models are highly informative: you don’t need long descriptions of how things work — the customer can see the layout in action! We find that, especially in an international business context, this makes communicating the ideas critically simpler. Chances of being somehow misunderstood are narrowed down to a minimum.”

Sales proposals seven times faster

The use of Visual Components in JOT Automation’s sales process has directly influenced the time spent on creating sales proposals. “Our quotation process and our review process are seven times faster now after we started using Visual Components,” Kyösti Soini says.

“In the past every sales person needed anything from one day up to one week to complete a sales proposal. Now the time it takes is something between one hour and one day. That is a big decrease from our point of view.“

Further reading

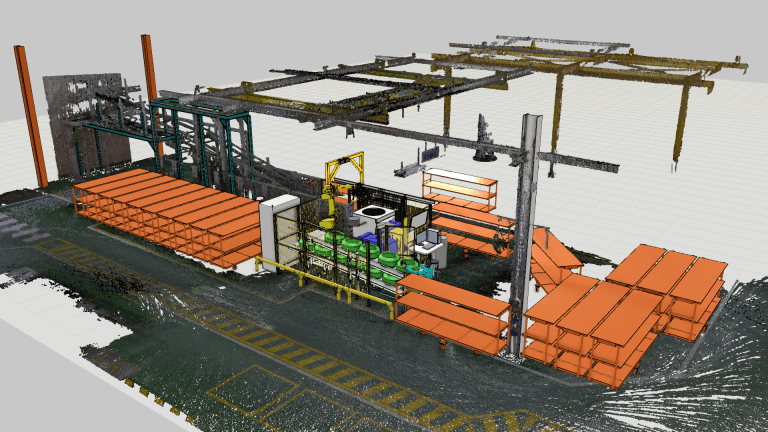

Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld...

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and...

Michelin streamlines manufacturing planning with Visual Components 3D simulation

When different teams see different things, it’s hard to move forward. That was the challenge at Michelin’s plant in Thailand, where engineering drawings and CAD sketches couldn’t always get production,...