ITRI case study

Find out how research institute ITRI uses Visual Components to present their manufacturing solutions

Support in promoting flexible manufacturing systems

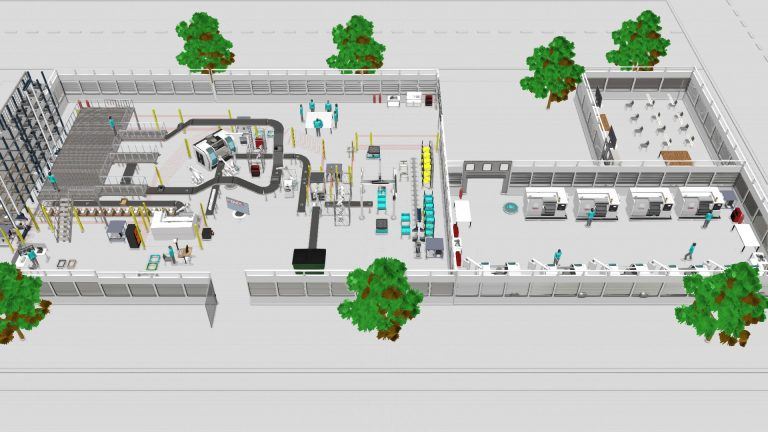

Industrial Technology Research Institute (ITRI) is a major Taiwanese research institute with research fields ranging from mechanical engineering to material science, biomedics, electronics and green energy. Their machine tool technology center focuses on machine, robot and controller design to provide customers with small flexible manufacturing cells.

To promote their flexible manufacturing system by presenting their offering more visually, ITRI adopted Visual Components as their design and development environment. They have also implemented an add-on module, which allows the software to connect directly to ITRI’s CNC and robot controllers. In total, the implementation took about three months to complete.

It is easy to start using Visual Components 3D visualization tools.

Dr. ShuoPeng Liang, Manager, Department of Intelligent Machine

Supported by a comprehensive training course and online documentation, adopting the Visual Components 3D simulation software was easier than expected. So far ITRI have been using the ready-made components provided with the online component library but in the future they are planning to also model their own components.

Cyber-physical manufacturing research

While their main use of the software is presenting their manufacturing solutions to potential customers, ITRI also sees a plenty of potential in using Visual Components in their future research. Their research project, funded in part by the government of Taiwan, focuses on creating new cyber-physical manufacturing systems (CPS). As it brings information from the machinery on the factory floor to computer systems, CPS is one of the key building blocks of Industry 4.0. Their long term vision is to build a factory floor simulator, which connects to multiple machines and multiple controllers simultaneously.

Further reading

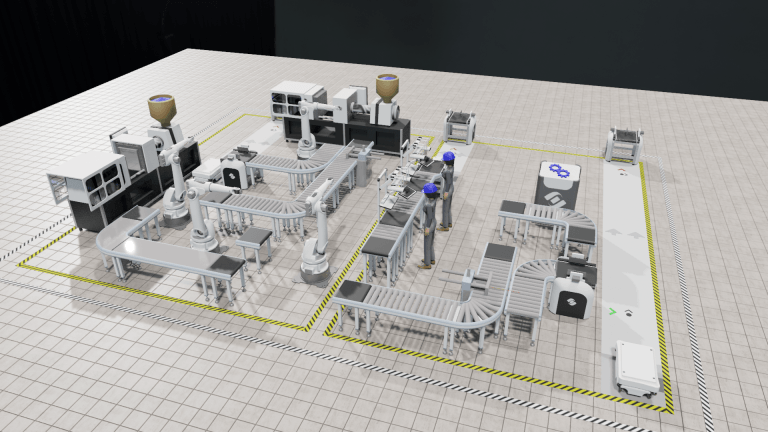

International robotics and simulation competition in China, and smart factory project

This case is about a large-scale international competition where hundreds of students participated in designing the digital twin of smart factories using Visual Components-based powerful simulation technology. Read more about...

Helping students accurately simulate production environments in real-time

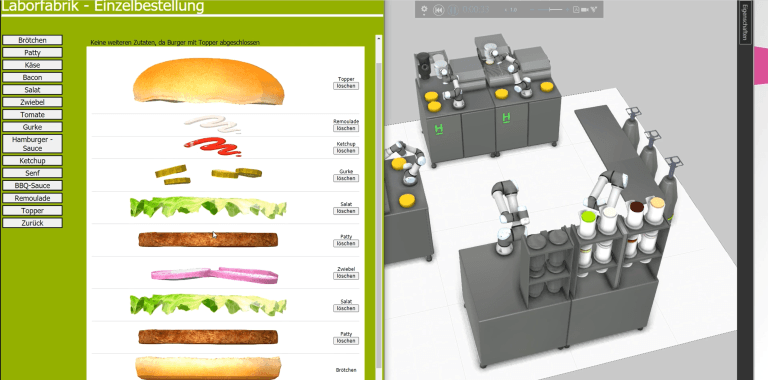

How can simulating an automated restaurant-like environment help students understand the power of simulation?

CU Coventry Case Study: Sparking Students’ Creativity When Designing Real-life Industrial Scenarios

A look at how students in Coventry University's Electro-Mechanical Engineering use Visual Components' 3D simulation software to carry out factory floor simulation.