INSPHERE boosts sales and customer confidence with Visual Components

INSPHERE, a leader in advanced metrology solutions, is dedicated to enhancing precision and efficiency in automated manufacturing. With their innovative IONA system, they address the need for accurate, real-time positional data of robots in various sectors. By integrating Visual Components in their operations, INSPHERE has been able to simulate and optimize complex setups before implementation, resulting in increased customer confidence and streamlined processes.

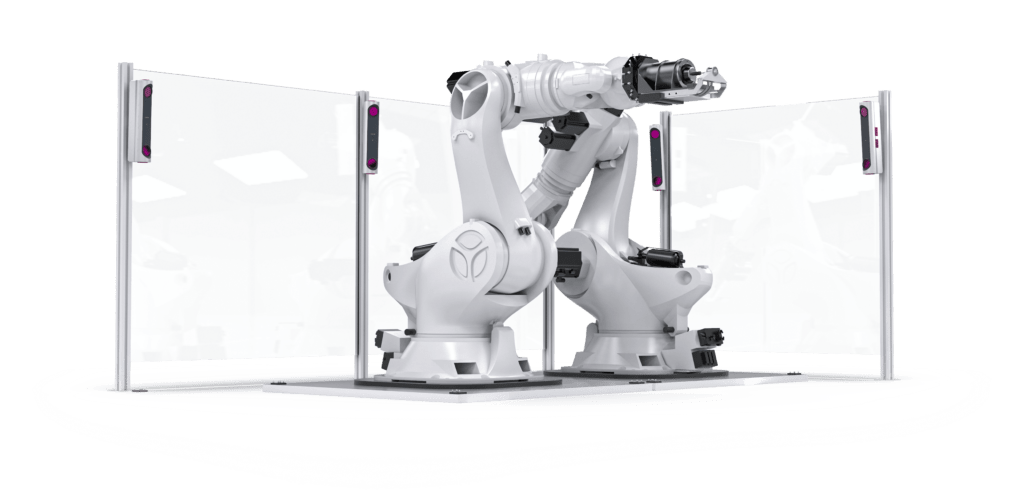

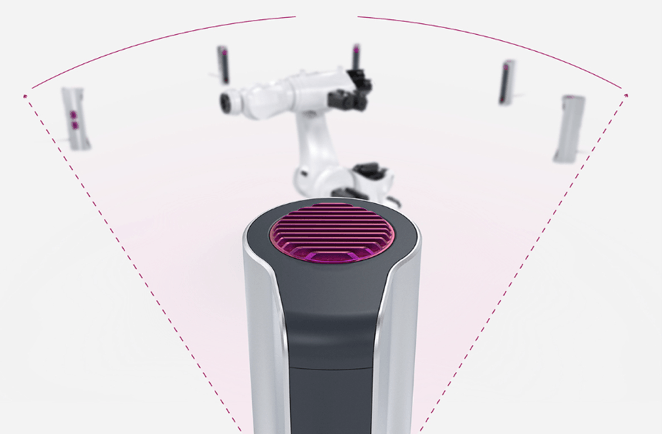

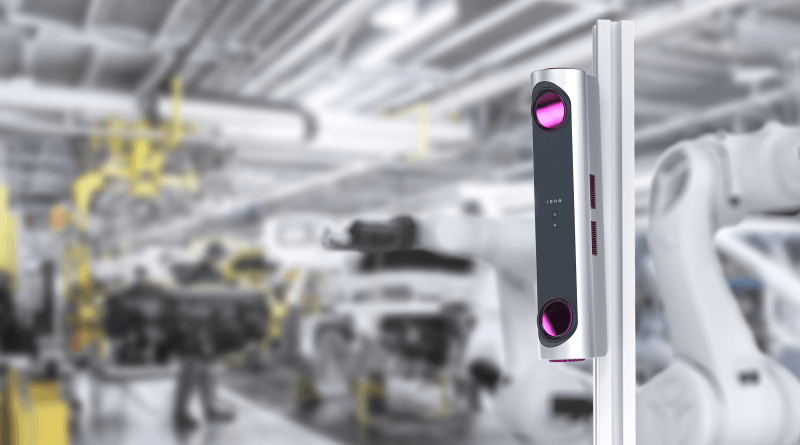

Founded a decade ago, INSPHERE initially specialized in large-volume metrology consultancy, serving the aerospace, nuclear and automotive sectors. They soon recognized a growing need for advanced metrology solutions for automation equipment, leading them to develop IONA, a network of photogrammetry sensors (nodes). IONA delivers precise 6DoF positional data to automated manufacturing processes, allowing for real-time updates to robot programs and processes. The positional data also allows for an accurate digital twin of the manufacturing system to be created, enabling the transition time from offline to production-ready processes to be drastically reduced.

Overcoming initial challenges

Before using Visual Components manufacturing simulation software, INSPHERE struggled to accurately simulate nodes within automation cells using traditional CAD packages. These tools didn’t offer the tools necessary for customers to fully understand the IONA system. Philip Silk, Operations Manager at INSPHERE, noted,

“Our reliance on a traditional CAD package fell short in delivering the detailed and process-specific simulations needed to ensure full customer confidence in the specification and integration of the IONA system.”

Visual Components bridged this gap with robust simulation capabilities, allowing INSPHERE to move beyond the limitations of CAD packages. This provided the level of detail and accuracy in planning that was essential for selling their high-tech automation solutions.

The INSPHERE team learned to use Visual Components independently, utilizing free online resources like the Visual Components Academy. The learning process was straightforward, even for engineers with limited automation backgrounds. This accessibility allowed the team to quickly become proficient, enhancing their ability to develop and implement advanced metrology solutions. Visual Components’ user-friendly interface and comprehensive support resources were crucial in this smooth transition.

Integrating Visual Components into sales and applications

Visual Components quickly became a cornerstone for INSPHERE’s sales and applications teams. The sales team uses the software to determine the optimal number of sensors for each customer’s unique application, ensuring efficient and tailored recommendations. Following in from initial studies, the applications team meticulously plans the placement of nodes and targets within robot cells, guaranteeing comprehensive visibility and precise measurement data capture. This dual usage showcases the flexibility and power of Visual Components across different stages of the project lifecycle.

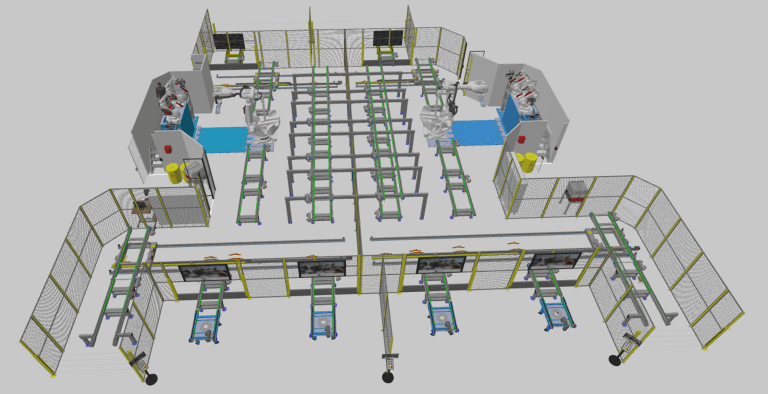

For example, when an aerospace customer needed an IONA system for a multi-robot, multi-process cell, the INSPHERE team imported a CAD file of the customer’s cell into Visual Components. They then replaced the basic robot models with models from Visual Components eCatalog to enable detailed manipulation and brought nodes and their fixtures and parts into the environment. The nodes were then strategically positioned to highlight any overlaps in working volumes and to check for potential visibility issues caused by the robots during the process. This detailed simulation provided the customer with visual evidence that the proposed solution would cover their working volume without process interference, demonstrating both the benefits and reliability of the system.

Benefits of using Visual Components

Externally, Visual Components has significantly boosted customer confidence through detailed simulations, clear integration plans and optimized node placement. The ability to present a virtual model of the customer’s setup allows INSPHERE to demonstrate the efficacy of their solutions convincingly. Customers can see firsthand how the proposed system will work within their specific environment, reducing uncertainties and accelerating decision-making in the sales process.

“This simulation capability has significantly reduced development time for these internal processes, allowing our team to operate more efficiently and focus on delivering high-quality solutions to our customers.”

Philip Silk, Operations Manager at INSPHERE

Internally, the software has improved efficiency and precision. The ability to simulate robot programs before physical deployment has reduced development time and minimized the risk of crashes and errors. This pre-emptive troubleshooting using Visual Components has helped ensure smoother implementations and quicker turnarounds, saving time and resources.

Customer feedback and competitive edge

“Overall, Visual Components has become an indispensable tool at INSPHERE, driving innovation, enhancing operational efficiency, and ensuring the delivery of reliable, high-performance metrology solutions.”

Philip Silk, Operations Manager at INSPHERE

Customers have responded enthusiastically to Visual Components. The visual simulations offer a clear, intuitive understanding of INSPHERE’s technology, enhancing comprehension and instilling confidence.

This visualization also helps secure buy-in from senior management, making proposals more compelling and credible during tender processes. The ability to visually communicate complex technical details helps bridge the gap between technical and non-technical stakeholders, ensuring everyone is on the same page.

Visual Components gives INSPHERE a competitive advantage by allowing them to present clear, visual evidence that their solution meets customer requirements. This capability sets INSPHERE apart from competitors who cannot provide such upfront visual proof. In the highly competitive field of advanced metrology and automation, this advantage can be decisive in winning contracts and fostering long-term client relationships.

Future plans with Visual Components

INSPHERE plans to develop additional tools on top of the Visual Components platform, focusing specifically on performance simulation tools within the software. As Phillip puts it,

“While best practices currently allow us to deliver high performance for our customers, we aim to enhance this by developing tools within Visual Components that enable us to test setups and predict performance values.

These new simulation tools will allow us to assess different configurations and provide accurate performance predictions to our customers. This will ensure that we can design and integrate the highest possible performance solutions, optimizing our systems to meet specific customer needs with even greater precision and confidence.”

Conclusion

Visual Components has enabled INSPHERE to clearly demonstrate to its customers the value provided by their solutions. INSPHERE is eager to leverage advanced features for more excellent operational value and precise solution design.

INSPHERE’s journey with Visual Components highlights the software’s transformative impact on technical sales processes. By providing detailed simulations and clear visualizations, Visual Components has enhanced customer engagement, improved operational efficiency and helped cement INSPHERE as a leader in advanced metrology solutions.

About INSPHERE

INSPHERE is the innovator of advanced metrology solution IONA, serving the aerospace, nuclear and automotive sectors. They developed IONA, a scalable network of sensors for automated manufacturing processes. In addition, they provide flexible robot tracking software, Renishaw robot commissioning and servicing solutions, and continue to offer laser tracker robot calibration and precise cell measurement services.

About Visual Components

Founded by a team of simulation experts and amassing over 25 years in business, Visual Components is one of the pioneers of the 3D manufacturing simulation industry. The organization is a trusted technology partner to leading brands, offering machine builders, system integrators and manufacturers a simple, quick and cost-effective solution to design and simulate production processes and offline robot programming (OLP) technology for fast, accurate and error-free programming of industrial robots.

Want to learn more about the benefits of our solutions for your business? Contact us today!

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

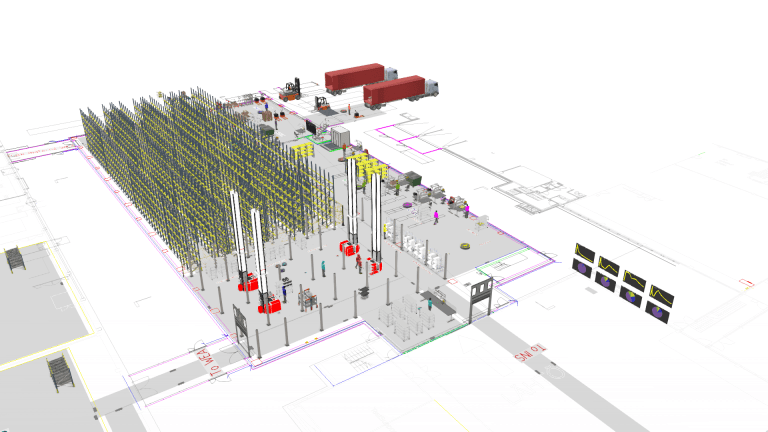

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to...

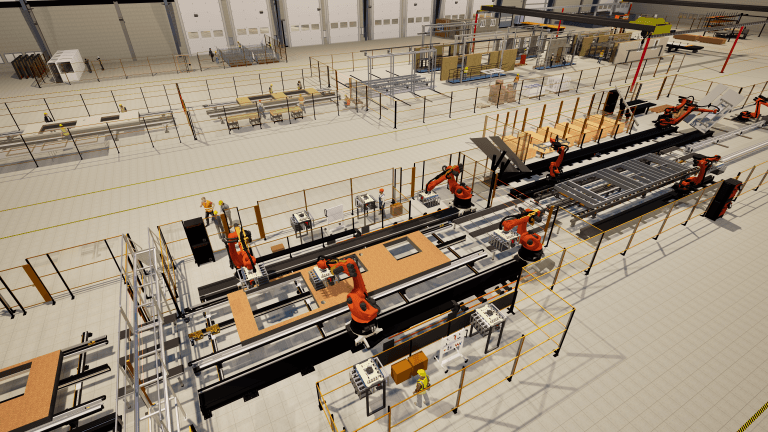

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more...