Offline programming for increased speed, quality, and productivity in the metal industry

HT Laser, established in 1989, is a system supplier and a flexible partner for the metal industry. HT Laser specializes in assemblies and component manufacturing, as well as custom-optimized and processed cuts. HT Laser is a pioneer in industrial laser and water cutting and one of the leading players in laser welding in Finland. HT Laser relies on Visual Component’s OLP software (previously Delfoi Robotics) for offline programming of robots.

Flexibility is key in small-batch production

HT Laser’s customers are mainly Finnish machine manufacturers, for whom it supplies various products as a subcontractor. Production is mainly in small batches, and the products are always tailor-made to the customer’s needs. In terms of productivity and profitability, this requires a lot of flexibility in production, systematic production planning, and the right systems, equipment, and software.

“The most important thing in subcontracting business is to be able to adjust production to the customer’s needs. Sometimes you have to be able to respond quickly when demand is high, and on the other hand, be able to reduce capacity when demand slows down. Flexibility is the key in this business. Offline programming of robots and Delfoi software (now known as Visual Components Robotics OLP) plays a key role in this,” says Janne Tuominen, Product Development Manager at HT Laser Oy.

Robotization is at the core of development

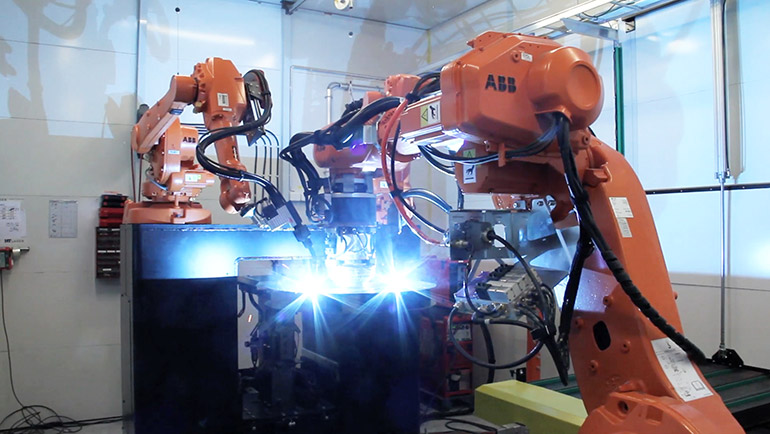

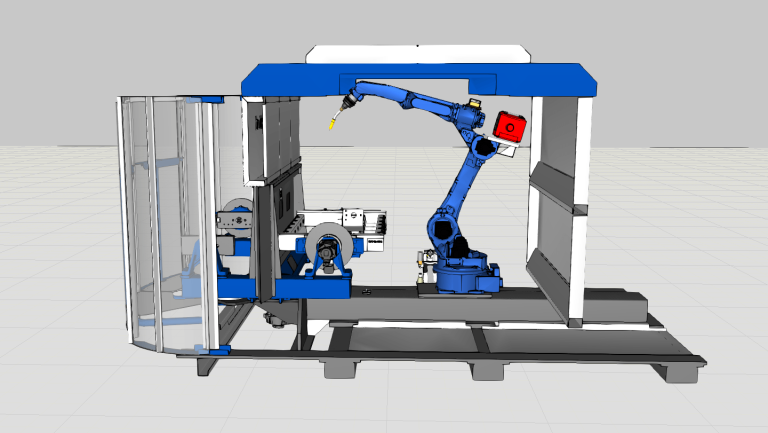

HT Laser has been using welding robots in production for about twenty years and they are used for welding various products. HT Laser and its subsidiaries use robots from several different manufacturers, such as KUKA, OTC, ABB and Yaskawa. The use of these robots is expected to increase in the future.

“We use robots for welding whenever good accessibility is possible, when the number of welding hours is high, or when the number of pieces to be welded is so large that a person can no longer do it. The benefits of using robots are that they can weld tirelessly and the desired quality is repeatable,” says Janne Tuominen, Product Development Manager at HT Laser Oy, and continues:

“Our goal has always been to increase the automation level of production, and Delfoi Robotics plays a key role in offline programming of robots.”

Offline programming of robots brings many benefits

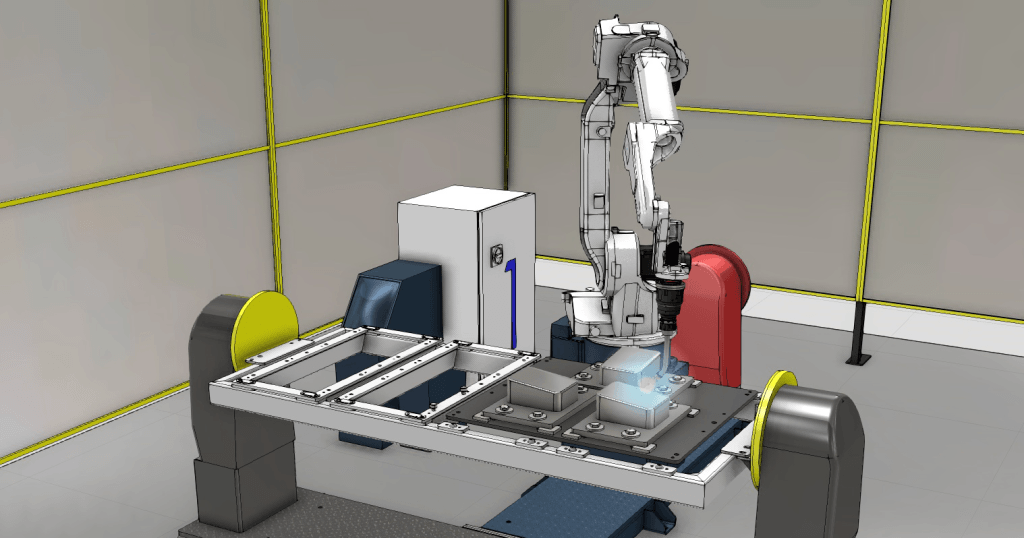

Offline programming is a production-uninterrupted method of programming robots, where the program for the robot is created on a computer outside of production. Delfoi Robotics’ product family covers software for numerous applications in almost all industrial robot applications and is compatible with all robots, regardless of brand. The Delfoi ARC software effectively utilizes the features of a 3D CAD model of a welded piece and welding information, making the generation of programs fast and error-free.

“The benefits of offline programming are realized in our production every day. The biggest benefit is time-saving as programming can be done without stopping production and expensive machines. Timesaving is also achieved by certain software macros that speed up the programming process. Offline programming also solves the problem if the welded piece is large or located in a place where it is difficult or unsafe to climb”, says Janne Tuominen, and continues:

“Offline programming is also location-independent, and we can program robots from one location to several of our factories. That is why we are investing in offline programming expertise and specialization in cooperation with Delfoi Robotics.”

Investment in automation and offline programming together

Investment in production automation and robotics requires ongoing development work. HT Laser is participating in the national AITOOLS1 development project, which aims to measure and verify the benefits of robotics through research. In the three-year project, machine learning models will be developed that are capable of dynamically adjusting and optimizing the robotic welding process. Delfoi Robotics is also participating in the joint project with VTT, Tampere University, and various companies.

“Our strategy is to continuously increase the level of automation. With regard to robotics and offline programming, I would say that we will strongly invest in and grow this aspect. It is good that we have a knowledgeable partner like Delfoi Robotics, with whom we build this future,” sums up HT Laser Oy’s product development manager, Janne Tuominen.

About Visual Components

Founded in 1999, Visual Components is one of the pioneers of 3D simulation. Visual Components’ 3D simulation helps industrial production companies design, test, optimize, and develop production lines as efficiently as possible. Visual Components Robotics OLP software, along with 3D simulation, form a software solution for digitalizing production systems that significantly reduces downtime, saves production time, and improves robotic programming processes.

Want to learn more about the benefits of offline programming for your business? Contact us today!

Further reading

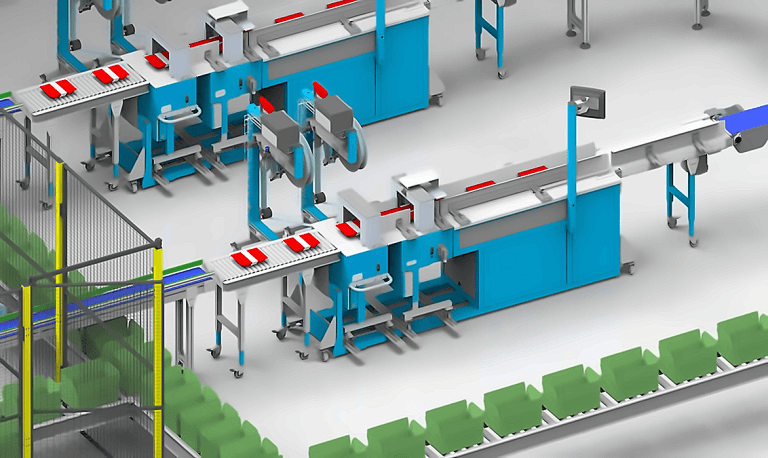

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

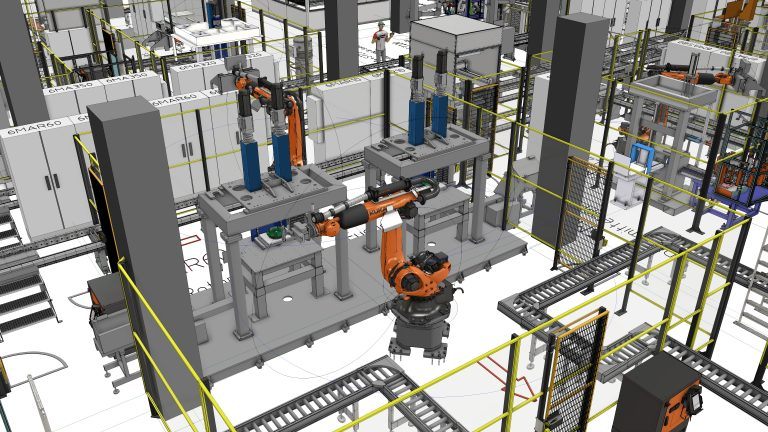

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...