Helping students accurately simulate production environments in real-time

How can simulating an automated restaurant-like environment help students understand the power of simulation?

Hochschule Hannover – University of Applied Sciences and Arts (HsH) – with a student body of about 10,000, offers 60 accredited courses in a broad range of subjects. One course in Process Management and Usability Engineering Industry 4.0, helps teach would-be engineers about how technology, processes, and people come together to create a productive, automated, and successful factory environment.

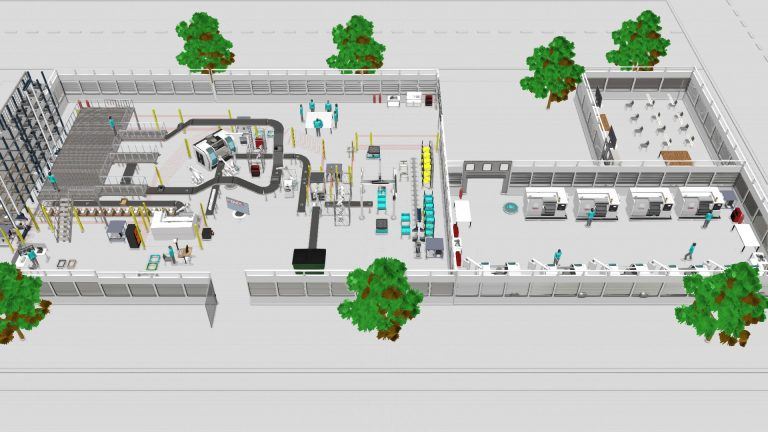

The course includes a lab where students can practice the theoretical part of Industry 4.0 with advanced software in a virtual environment.

HsH acquired Visual Components software in 2018 for this purpose, to help simulate a production environment in real-time.

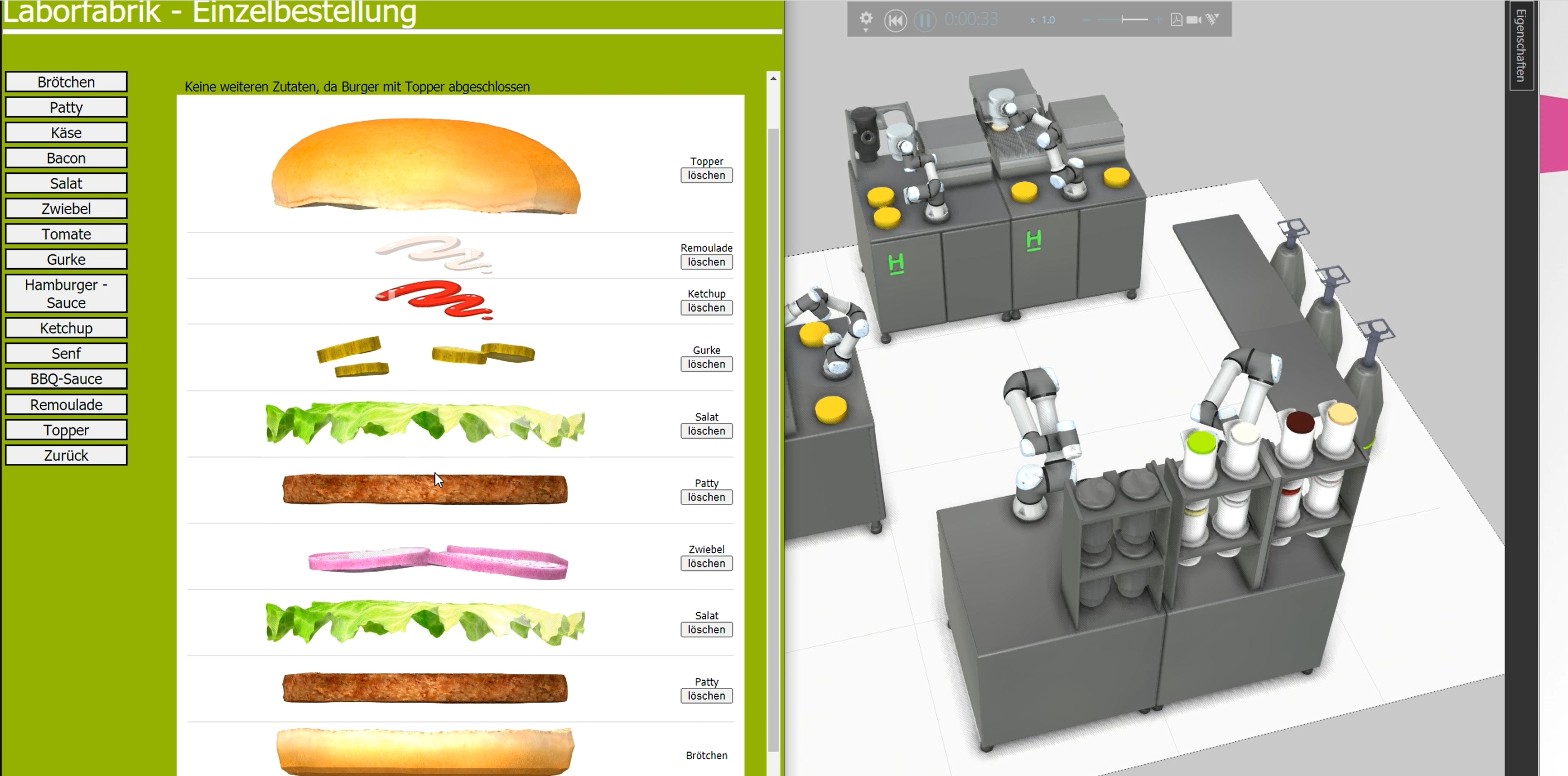

Simulating a restaurant-like environment – layer by layer

One of the program’s key assignments consists of students creating a webshop on which orders for hamburgers can be made in a restaurant-like environment. Students work in Python to process the orders coming in from the webshop and each student’s project runs via an Open Platform Communications Unified Architecture (OPC UA) to connect to the simulation.

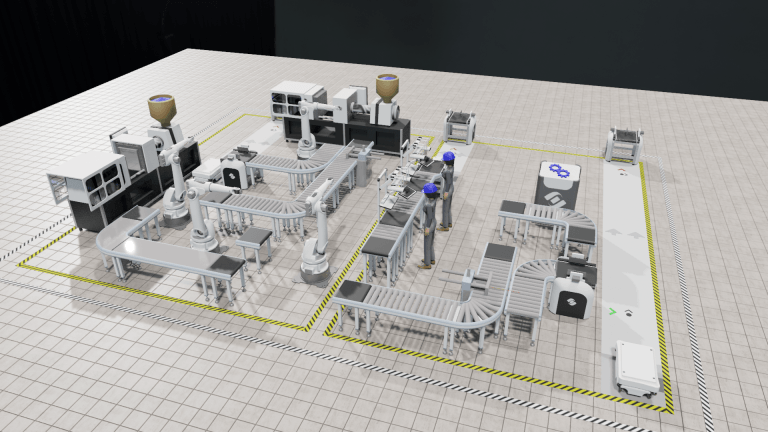

Students use Visual Components for the virtual commissioning experience, specifically as it pertains to setting up a process and executing that process. By using the software, students are able to virtually simulate a production plant in real-time and experience everything from programming to control.

Full virtual commissioning experience

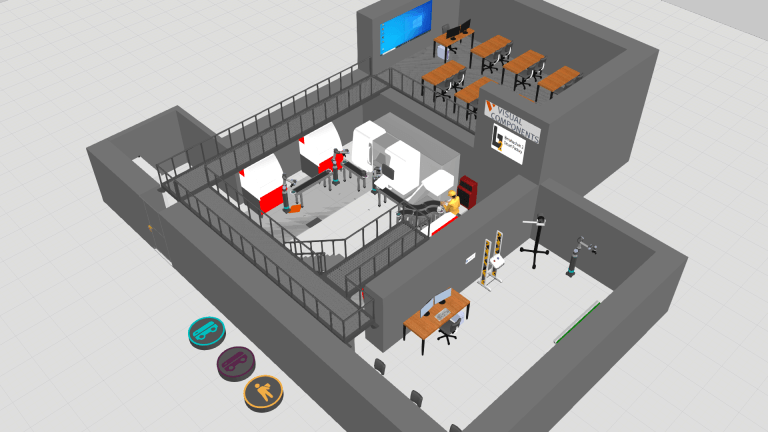

The primary decision-making factor for HsH to integrate Visual Components into the program was the OPC UA interface, which can access multiple machines and not only a robot controller. The concept was there from the beginning, and the software fit perfectly with the program’s needs. Also, the possibility for multiple students to access a 3D experience and take a look at the same factory floor they are working on was something the individuals running the course and the students alike much appreciated.

“Visual Components offers a full virtual commissioning experience,” says Dr.-Ing. Jens Hofshulte, Process Management and Usability Engineering Industry 4.0 Course Director. “It’s beneficial to have remote control access for simulation so that you have the opportunity to program and control a real factory environment remotely. Experiencing such a thing is truly unique.”

Further reading

International robotics and simulation competition in China, and smart factory project

This case is about a large-scale international competition where hundreds of students participated in designing the digital twin of smart factories using Visual Components-based powerful simulation technology. Read more about...

CU Coventry Case Study: Sparking Students’ Creativity When Designing Real-life Industrial Scenarios

A look at how students in Coventry University's Electro-Mechanical Engineering use Visual Components' 3D simulation software to carry out factory floor simulation.

RDF Nuremberg Case Study: With Enthusiasm Towards Digital Transformation

With a digital twin of a smart factory, a technical college in Nuremberg, Germany makes its students fit for the digital transformation.