fsk engineering Case Study

A fully functional 3D simulation brings the two dimensional CAD drawing to life.

Using 3D Simulation in engineering

fsk engineering GmbH provides online and offline robot programming solutions, robot simulations and automated systems up to a full digital factory. Their main customers are in the automotive industry but they also serve customers in the agriculture and food industries.

fsk engineering has been using Visual Components software to design and engineer factory layouts. We therefore let Christian Sühwold and Nils Kühle, the founders of fsk engineering to tell us how the software has helped them run their business.

Simulation is our door opener when meeting new clients and prospects.

Christian Sühwold, CEO, fsk engineering

With 3D simulation it´s easy to visualize our complex visions of production lines or complete manufacturing halls to the clients. Through 3D simulations, we seal the deal and get an order for commissioning and delivering the robot almost every time.” says Christian Sühwold, CEO and co-founder of fsk engineering.

Simulation brings the two dimensional CAD drawing into real life

Compared to working with CAD files, Visual Components 3D simulation saves a lot of time – especially when working directly with designers. CAD alone is static and it is therefore often hard to visualize the reality of the actual production line or how the robots work.

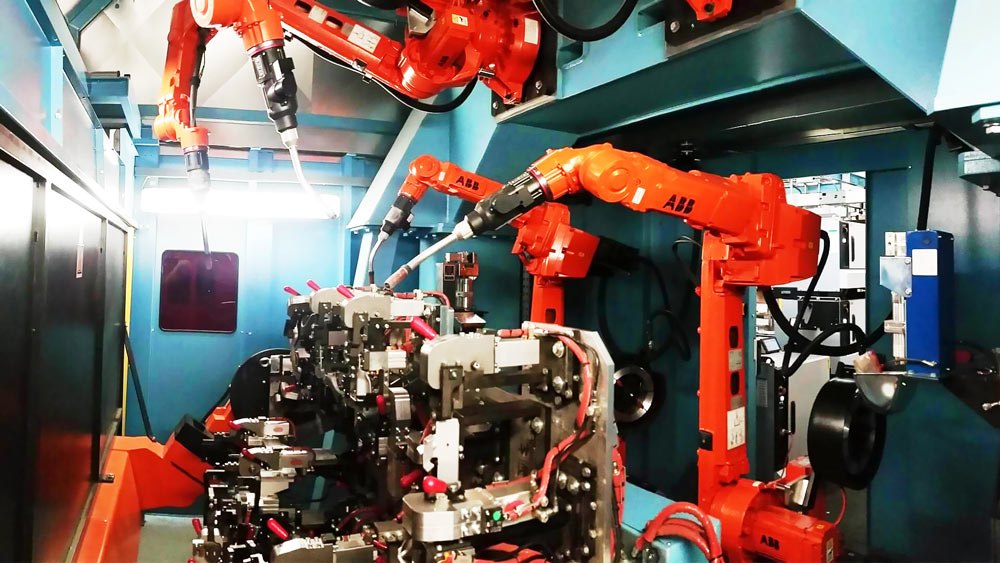

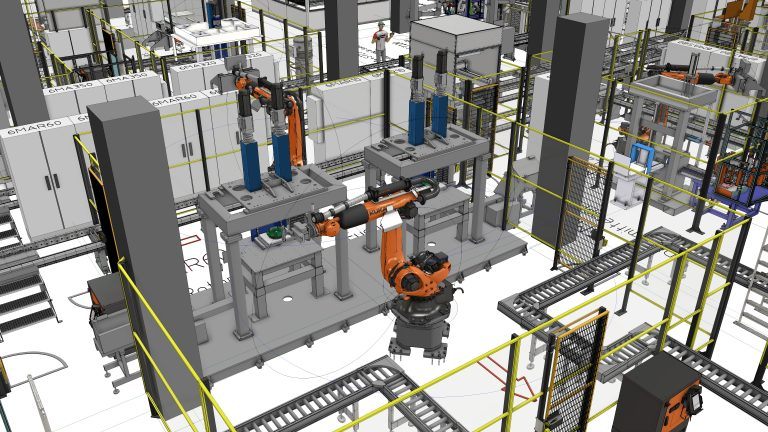

Simulation played an integral part in the quoting and implementation phase of a robot cell implemented at Strothmann Machines & Handling GmbH. A simulation was created taking all construction and reachability constraints into account. (left: real robot cell; right: simulated cell)

Visual Components’ 3D simulation software makes this a lot easier. A fully functional 3D simulation simplifies and brings the two dimensional CAD visualization into real-life. Time is saved as CAD models that are around 80% ready can be imported to the simulation software and analyzed profoundly.

CAD information alone lacks detailed information on how robots should be positioned and how they should function. Understanding the realities of the factory is therefore difficult for designers only utilizing CAD files.

“Cable assemblies, cable channels, hall pillars… All these things can be viewed from various angles. This makes it easy to understand how everything works. ” says Nils Kühle, CEO and co-founder of fsk engineering.

Simple to adopt, easy to use

For fsk engineering, starting to use Visual Components software was a simple step. After a simple three day training they were able to make presentable layouts, visualize robot movements, combine components and analyze robot cycles themselves.

Especially when running robots, it’s critical to spot potential sources of error early on as they can result in high costs at the construction site.

Nils Kühle, CEO, fsk engineering

Compared with their competitors who use software created by robot manufacturers, fsk engineering is able to simultaneously work with and integrate robots from all major manufacturers in the same software. That’s one the main reasons why Visual Components is their number one choice for creating quick simulations and performing feasibility studies.

About fsk engineering

fsk engineering is a German based service provider working in the field of online/offline robot programming and the simulation of robot cells as well as complete automated systems up to the full digital factory.

For more information visit www.fsk-engineering.de

Further reading

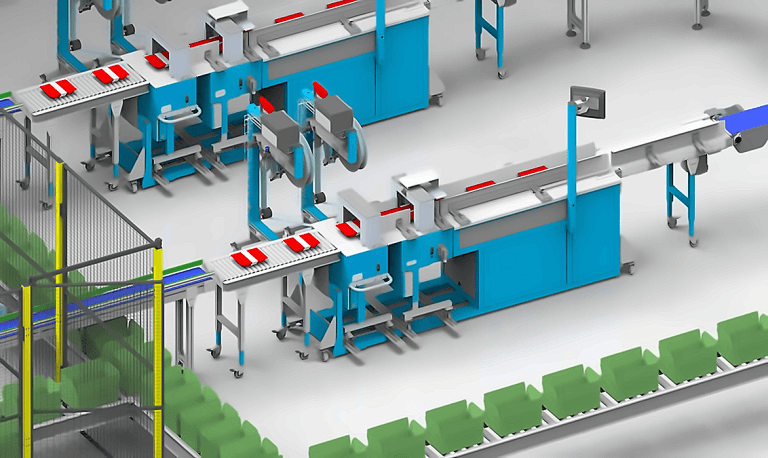

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

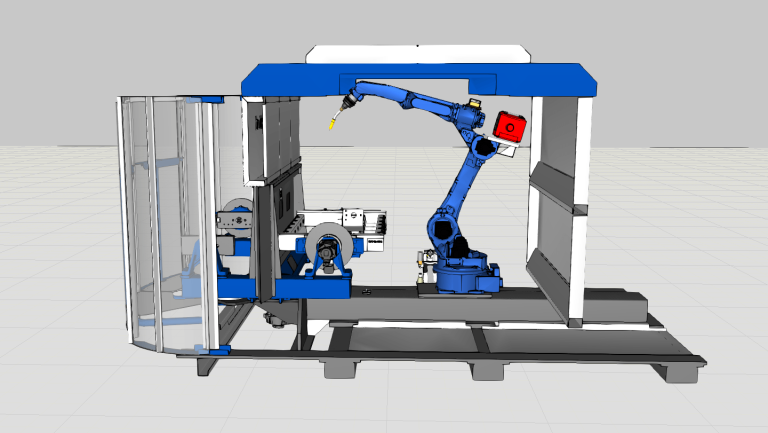

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...