Fill Case Study

See how Fill is using Visual Components 3D simulation to optimize resources and reduce costs.

Visualization as a key selling point

Fill GmbH is a global mechanical engineering and factory construction company from Austria. Since 2009, Fill has used Visual Components’ 3D simulation software to support its sales, production planning and engineering.

Before adopting Visual Components, the company went through an extensive review of 69 different simulation tools, ultimately choosing Visual Components due to its proven track record and excellent partner support.

Our customers’ first impressions of the simulations have always been above all positive.

Alois Wiesinger, M.Sc. (Tech.), Product Developer at Fill

3D Simulation – the implementation phase

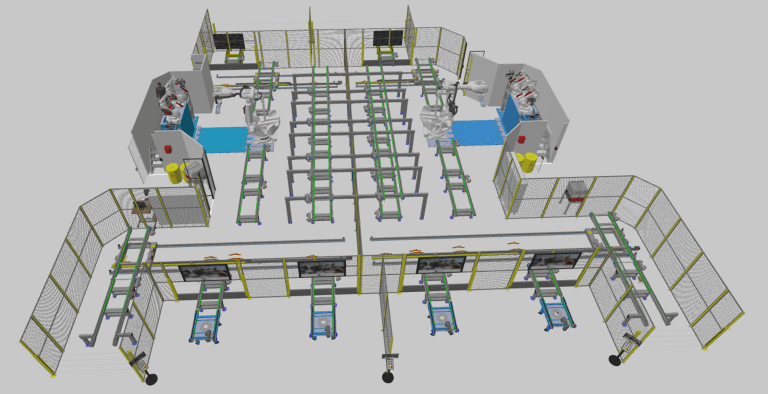

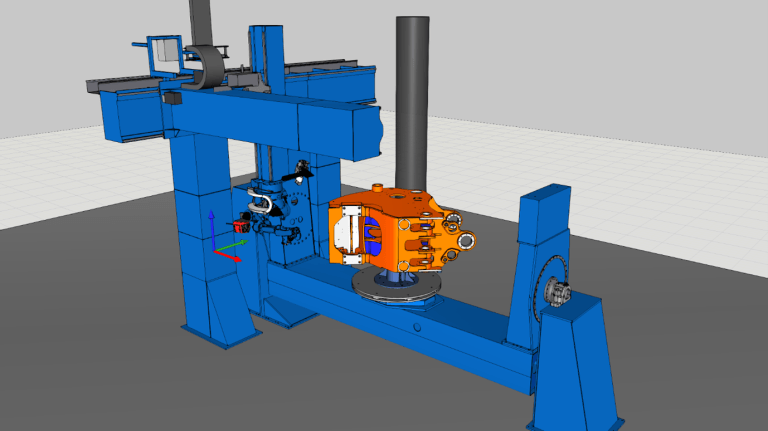

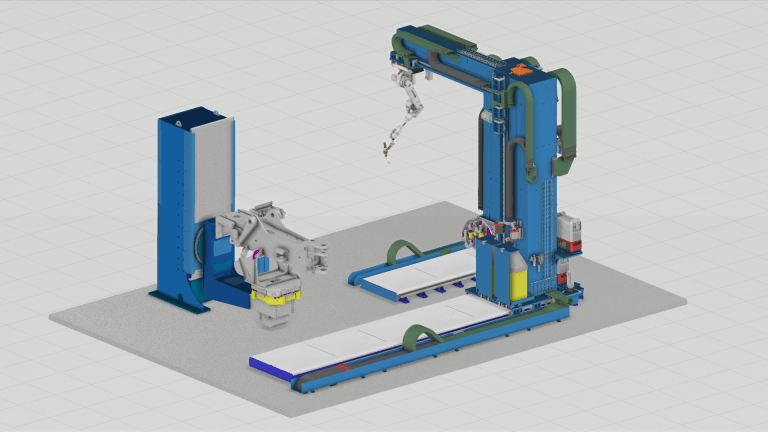

During the nine-month implementation phase the project team created the first simulations and the parallel models for a standardized component library. While standard industrial components such as conveyors and robots could be taken from Visual Components’ component library, numerous special components were modelled individually by the partner DUALIS.

Already the first 3D simulations received a great response from Fill’s customers.

Simulation enables system optimization

Simulation benefits not only sales and marketing, but also the actual factory design. Simulation helps in optimization and especially in avoiding errors in advance.

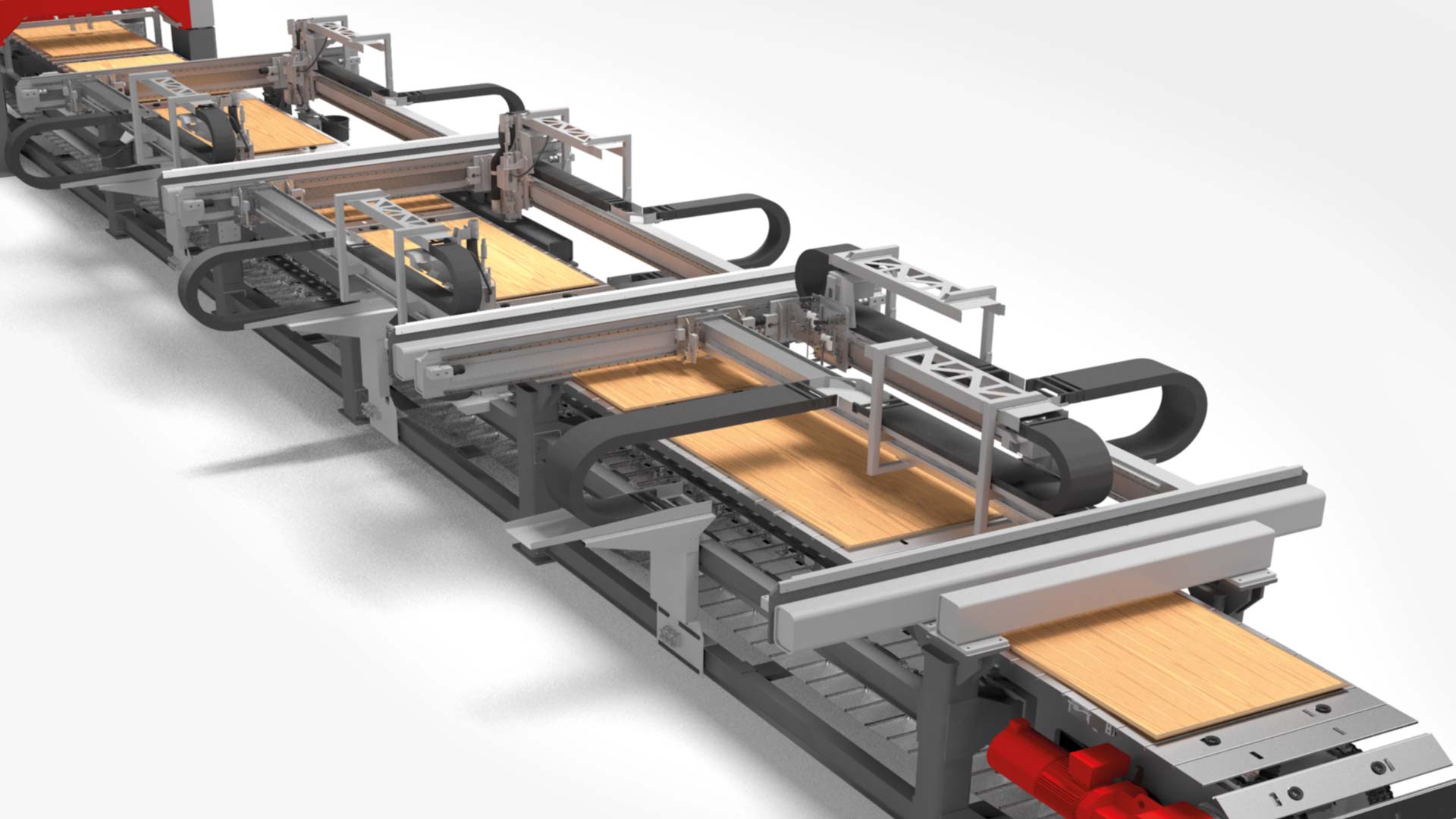

A practical example comes from the wood processing industry. Initial calculations indicated an output of 500 planks per hour for the production line. However, the simulation showed that the output would actually be as few as 400 planks per hour as flaws in the drive reduced the feed rate.

Using simulation, the central bottleneck was identified. The project planners then optimized processes and increased the performance of some resources. In the end, an output of 500 planks per hour was achieved.

“It was only through the simulation and its realistic modelling of dynamic interactions that we were able to discover the weak points of the system at an early stage and ultimately meet the requirements to the complete satisfaction of all concerned.” says Alois Wiesinger.

As the example indicates, simulation can be an invaluable asset in reaching the goals for any production line.

It was only through the simulation and its realistic modelling of dynamic interactions that we were able to discover the weak points of the system at an early stage and ultimately meet the requirements to the complete satisfaction of all concerned.

Alois Wiesinger, M.Sc. (Tech.), Product Developer at Fill

Further reading

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,...

Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld...

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and...