FFG Feeler – Optimizing Flexible Manufacturing Systems with Visual Components

Discover how FFG Feeler designed and optimized a Flexible Manufacturing System using Visual Components 4.0.

Fair Friend Group (FFG) is a Taiwan based industrial conglomerate with over 90 companies operating in the fields of Machine Tool Technology, PCB, Industrial Equipment and Green Technology. FEELER is the overseas marketing brand for the machine tool division of FFG, which has 37 machine tool brands and 50 manufacturing bases located throughout the world. Its product portfolio includes vertical/horizontal turning and milling, 5-axis machining center, automatic production system and all line equipment.

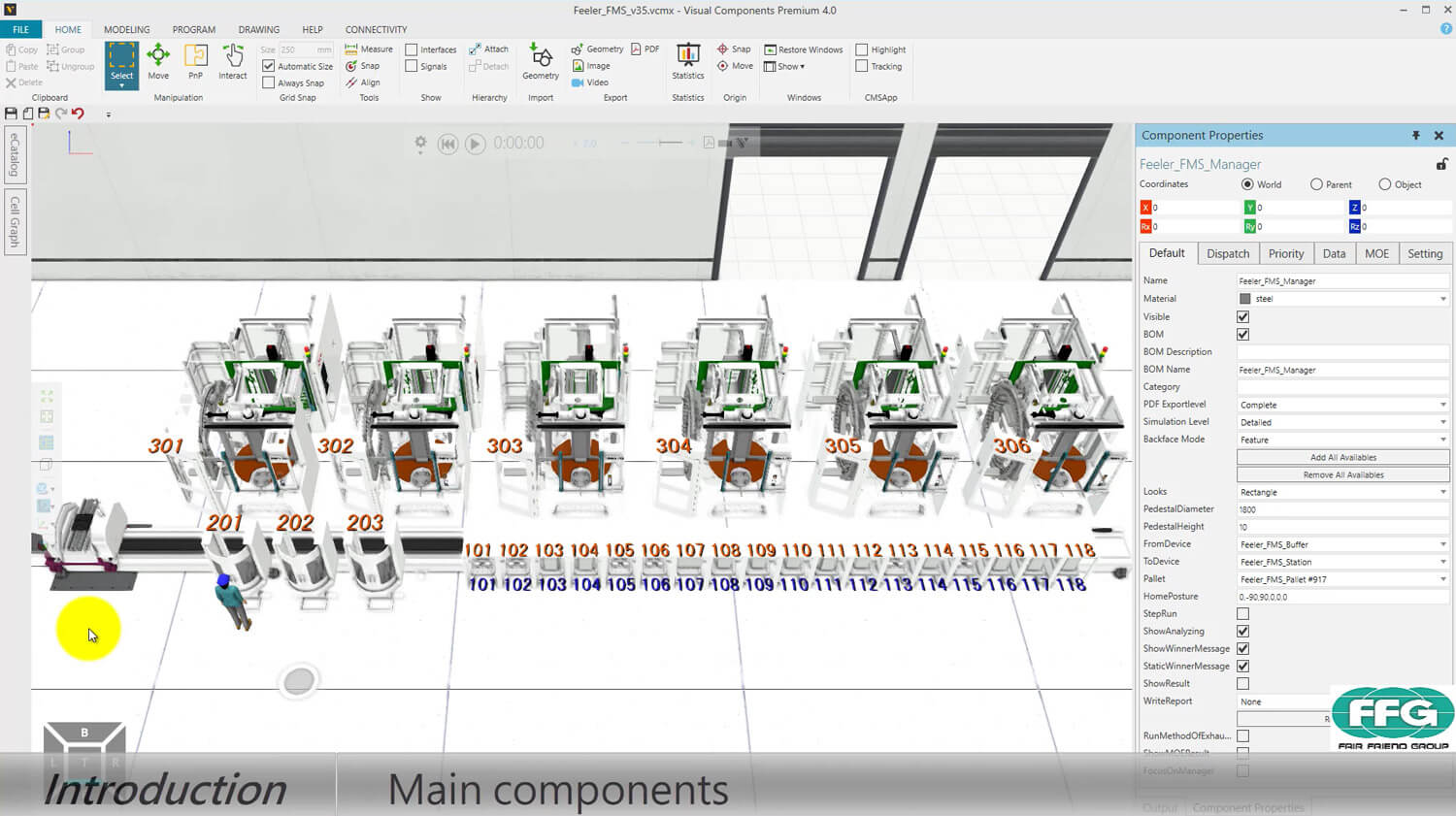

As a provider of turnkey production solutions, FEELER works with manufacturers to design and implement the optimal solutions for their production needs, often using advanced 3D manufacturing simulation software. They shared an example of a recent project they completed for the design of a Flexible Manufacturing System (FMS). Using Visual Components 4.0, FEELER analyzed multiple layout configurations and production scenarios to determine 1) the optimal number of CNC machines, and 2) the transport priority for the Rail Guided Vehicle (RGV). Check out the video to see how they did it!

How FFG FEELER used Visual Components to design an optimal FMS solution:

- Test dispatch list off-line to optimize the system

- Determine optimal # of Buffers

- Determine optimal # of Stations

- Determine optimal # of Machines

- Determine optimal # of Labor resources

- Determine optimal RGV transport priority setting

Further reading

CNC-ing clearly now: boosting proposal speed and client understanding with Visual Components at Mazak UK

Mazak UK, part of a global leader in CNC machine tools manufacturing, faced significant operational challenges, particularly in conveying the complexities of their Palletech system using traditional 2D drawings. This...

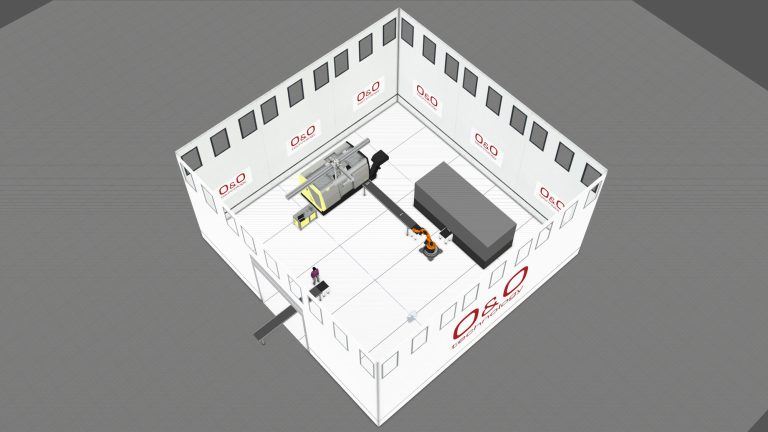

ONO Technology & SMB Technics Project Case Study: A Winning Partnership Lands a Key Project

Learn how SMB Technics and ONO Technology used Visual Components to design, optimize and validate the complete manufacturing line.

Fastems Case Study

Fastems increased the amount of proposals sent by a whopping five times with Visual Components software.