Faurecia Case Study

See how Faurecia uses Visual Components’ 3D manufacturing simulation software to develop and improve their production lines.

Improving Faurecia’s production lines with 3D simulation

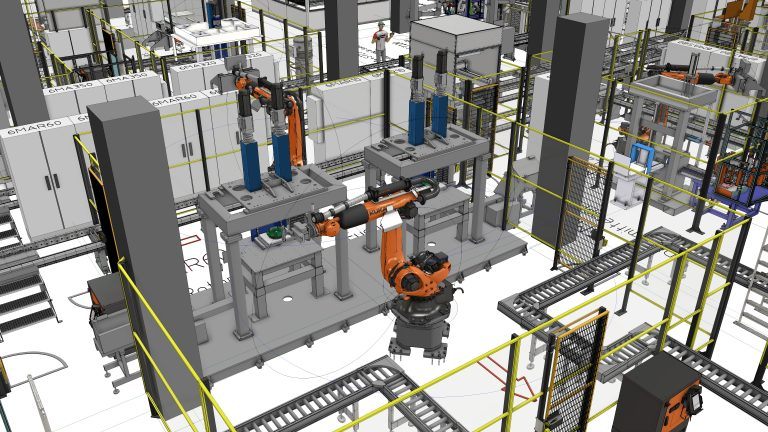

As one of the biggest global suppliers of car seats, optimized production processes and quality assurance are crucial for Faurecia in strengthening and maintaining their position. To help develop and improve their production lines, DUALIS IT Solutions – the largest distributor of Visual Components in German speaking countries – introduced Visual Components’ 3D Simulation as a solution.

Realizing Faurecia’s vision through 3D

3D simulation is used already in the early stages of planning the production lines and processes. Simulation helps to visualize material flow and internal logistics supply – along with virtual system validation and sales support.

“We have used simulation for decades. However our previous software didn’t match our growing needs for more flexible solutions”, explains Hartmut Beisner from the Manufacturing Support Function in Faurecia Automotive Seating from Faurecia GmbH.

Faurecia started searching for more flexible software to meet their growing simulation needs. Visual Components was ultimately chosen as the solution for the creation of new production lines and the standardization of existing lines.

Digitalizing the factory with 3DCreate and 3DRealize

Faurecia uses Visual Components’ 3DCreate and 3DRealize software (which are no longer available and have been replaced by the Visual Components 4.0 manufacturing simulation product line, now called Essentials, Professional, and Premium). As a more engineering oriented tool, 3DCreate serves as a basis for analysis and optimization for detecting and solving problems in advance.

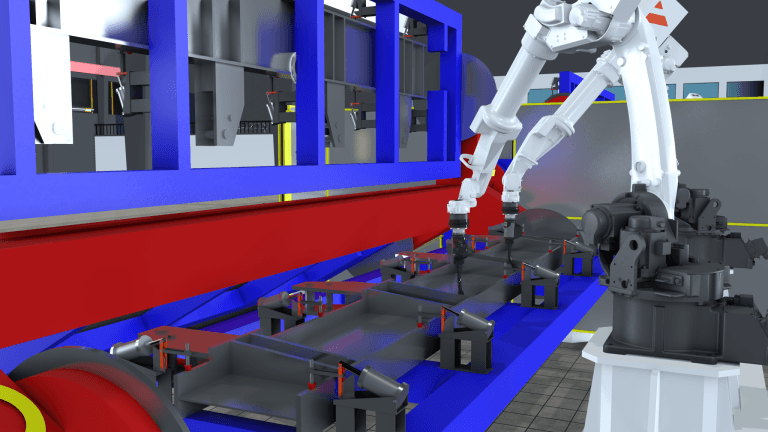

3DRealize on the other hand makes the sales process easier. Simple drag and drop tools enable the creation of customised 3D layouts, which enables the visualization of production line layouts already in the sales stage to help support investments decisions.

Virtualized material flows and job assignments

With the help of Visual Components’ products, Faurecia is able to show, among other things, the transport of individual components between welding areas. The software indicates if the worker-to-machine ratio is correct and whether the transport times correspond as planned. Are there any weaknesses in the system? How many people and vehicles are needed in the transport process? These and many other questions can be answered with simulation.

Simulation helps to plan the optimal production processes and the ideal content of work for each worker. The component library has a strong focus on the simulation of workers, their job assignments and related material supply.

Flexibility is the key.

Hartmut Beisner

“Product cycles are constantly getting shorter, so a company like us needs flexibility in the production process. It is possible that the equipment gets dismantled or removed and used for other projects,” Hartmut Beisner continues.

The simulation of the material flow and the close cooperation with DUALIS enables Faurecia to respond to changes and to visualize the workflows before commissioning the production line.

Further reading

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

BENTELER rolls out the production technology of tomorrow with the help of Visual Components

Together with BENTELER Automobiltechnik, Karlsruhe Institute of Technology uses modern factory planning software from Visual Components to develop innovative production technologies.

NIMAK Case Study: There Would Be No Cars Without This Company

In this case study, we’ll show you how NIMAK GmbH, the inventor of the robot welding gun and a leading manufacturer in the field of industrial joining technology, uses Visual...