Fastems Case Study

Fastems increased the amount of proposals sent by a whopping five times with Visual Components software.

How has Fastems benefited from collaborating with Visual Components?

Fastems, an independent robot integrator with over 20 years of experience in the machining industry, is a major player in the field of robot integration. The company employs 500 people worldwide and since its founding in 1990, Fastems has delivered over 2000 robot applications.

Visual Components and Fastems have worked together since 2007. According to Mika Laitinen, Sales Manager in Robotics, the collaboration has provided Fastems with many valuable benefits, the most remarkable of which is the increase in sent proposals.

With Visual Components Fastems has been able to make 5 times more proposals than before. Another key benefit for Fastems is the hours and days saved in layout planning time. Visual Components has also been able to support Fastems’ independence from different robotics brands.

From 50 to 250 proposals a year

Without a doubt, the business area within Fastems that has been impacted the most by the Visual Components collaboration is sales.

In the past Fastems, much like many companies in the industry, relied on CAD software to support their sales process. The main problem was that even if the sales organization had the capacity to scale up, sales materials, such as layout plans and illustrations were often held back on the desks of layout planners.

“In the past we were able to make 50 proposals a year,” says Mika Laitinen. “We could clearly see that there was great potential in our sales funnel that we just could not reach with our CAD software.

Switching to Visual Components in our sales processes really gave us the opportunity to tap into that potential.”

Displaying the layouts in beautiful 3D PDFs

Another clear advantage of the Visual Components solutions for Fastems is the possibility of presenting layout plans in 3D.

“There is a huge difference between a layout in the usual PDF format compared to a 3D PDF. The client can zoom into any detail in the layout and, more importantly, they can actually see the plan in action!”

As a Visual Components user, Fastems has been able to send out five times more proposals than before. “We would never have been able to create layouts this fast with our old CAD software,” Mika Laitinen says.

Today, Fastems makes 200 – 250 proposals each year.

“The process goes so that the sales people work out clear specifications for each client case and send them over to Fastems FI. At Fastems FI, it now only takes a short time to create really detailed simulation layouts based on those specifications with Visual Components.”

“So, basically the layout proposal is back in the hands of the sales person within a really short timeframe,” says Mika Laitinen.

We would never have been able to create layouts this fast with our old CAD software.

Mika Laitinen, Sales Manager Robotics, Fastems

Multiple robot brands on one platform

Simulation technologies are commonly used in the field of robot integration, but very often those simulations are robot-specific.

Fastems operates independently of any specific robot brand. With Visual Components, Fastems was able to bring multiple brands or FMS to a single platform.

“We are an open integrator, so we do not want to be too tied to one or two brands of robots. Now, instead of struggling to maintain competence for all kinds of different robot brands and their very specific sets of tools, we just use Visual Components as our platform. That’s pretty great,” Mika Laitinen says.

Less time programming: from 4 days to 2 hours

Visual Components has provided Fastems with the opportunity to significantly save time in robot programming.

“We are able to do 90% of programming in simulation. Sure, there are restrictions in some processes, and we need to do a bit of manual programming too, but, honestly, the time we save is measured in days,” Mika Laitinen says.

“Overall, our robot programming time was reduced from an average of 3-4 days to only 2-3 hours. In robotic cell setup, the time used has gone down from 5-10 days of manual programming work to 2 days with Visual Components offline programming.”

Overall, our robot programming time was reduced from an average of 3-4 days to only 2-3 hours.

Mika Laitinen, Sales Manager Robotics, Fastems

Why did you choose Visual Components?

Mika Laitinen is confident the collaboration between Fastems and Visual Components will continue. In fact, using Visual Components for layout planning will be expanded to a number of new business areas within Fastems.

“Visual Components is a really good partner. We can actually influence what we get, and we really appreciate that. The Visual Components solutions are simple, good looking and easy to use, and the fact that a product this effective is also affordable really sealed the deal for us. I think the results speak for themselves.”

The Visual Components solutions are simple, good looking and easy to use, and the fact that a product this effective is also affordable really sealed the deal for us.

Mika Laitinen, Sales Manager Robotics, Fastems

Further reading

CNC-ing clearly now: boosting proposal speed and client understanding with Visual Components at Mazak UK

Mazak UK, part of a global leader in CNC machine tools manufacturing, faced significant operational challenges, particularly in conveying the complexities of their Palletech system using traditional 2D drawings. This...

ONO Technology & SMB Technics Project Case Study: A Winning Partnership Lands a Key Project

Learn how SMB Technics and ONO Technology used Visual Components to design, optimize and validate the complete manufacturing line.

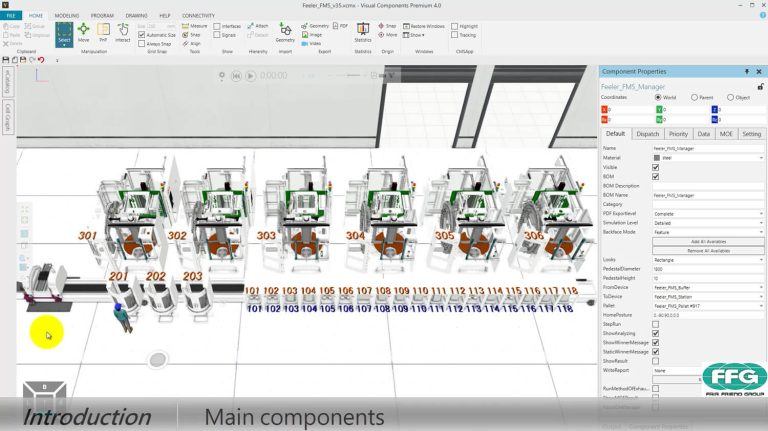

FFG Feeler – Optimizing Flexible Manufacturing Systems with Visual Components

Discover how FFG Feeler designed and optimized a Flexible Manufacturing System using Visual Components 4.0.