Europlacer Project Case Study: Designing Total Line Solutions in a Flash

In this case study, we’ll show you how Europlacer, the world’s largest independent global supplier of SMT pick-and-place machines, uses Visual Components to design and sell assembly solutions to customers in the global electronics industry.

A Global Supplier of SMT Machines, Looking to Scale

Europlacer is the world’s largest independent global supplier of surface-mount technology (SMT) pick and place machines. Their product portfolio includes a variety of SMT pick and place machines, storage solutions, PCB screen printers, and integrated software systems for production and process control.

Europlacer sells its solutions both directly and via a global network of distributors, and supports both channels with creating sales proposals. For a global company that produces a high volume of sales proposals every year, this amounts to a sizable workload. Before starting with Visual Components in 2018, Europlacer’s proposal workflow was slow and in need of improvement.

“We were using PowerPoint to create 2D drawings,” said Pierre Chatain, Product Marketing Manager. “It would take at least one day to create these and even then, they carried a high tendency of inaccuracies, so they had to go through several rounds of changes internally before we shared them with customers.”

They realized the need to improve the efficiency of their proposal response workflow and set out to find a tool that could support this. They also wanted a tool that could produce quality graphics and video of the solutions they were designing.

“The cost of a new product line exceeds several hundred thousand euros,” said Pierre. “So, the customer expects to have some nice visuals of what they’re purchasing.”

Europlacer selected Visual Components due to its ease of use and high-quality graphics.

“It was quite easy to create models of the machines and options we produced here in the French factory,” said Pierre. “Now that the models are in our library, it’s very easy to create new layouts and configurations, as well as generate drawings.”

“As a bonus, we’re also able to share videos of our simulations with customers.”

It was quite easy to create models of the machines and options we produced here in the French factory. Now that the models are in our library, it’s very easy to create new layouts and configurations, as well as generate drawings.

Pierre Chatain, Product Marketing Manager

The Project: A U.S. Based PCB Manufacturer Wants to Increase Capacity

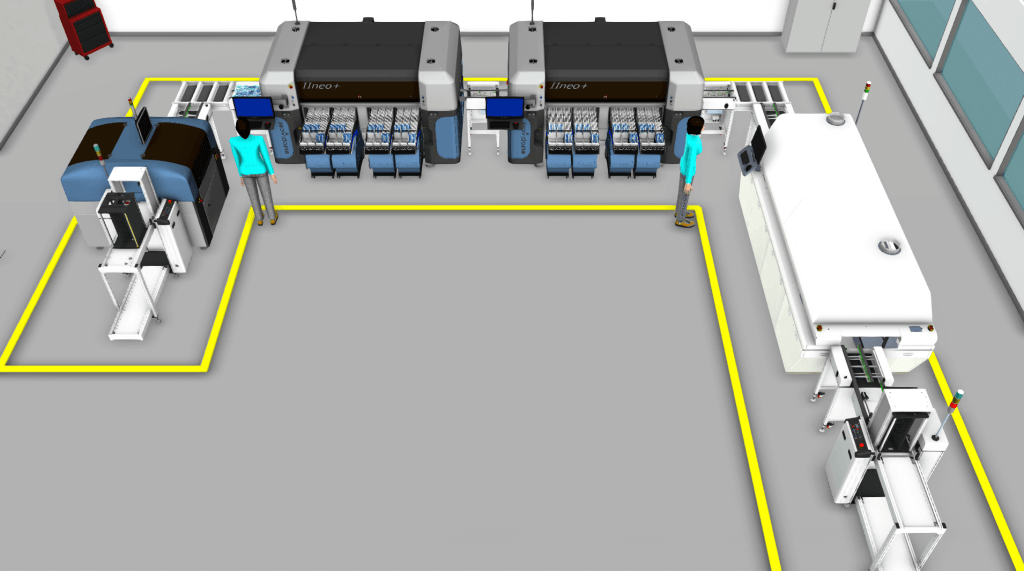

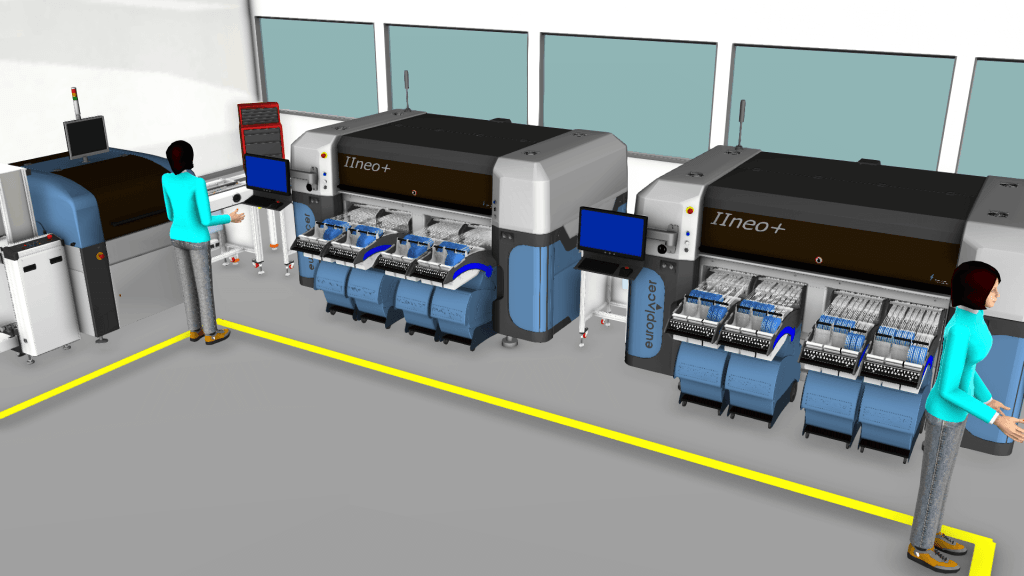

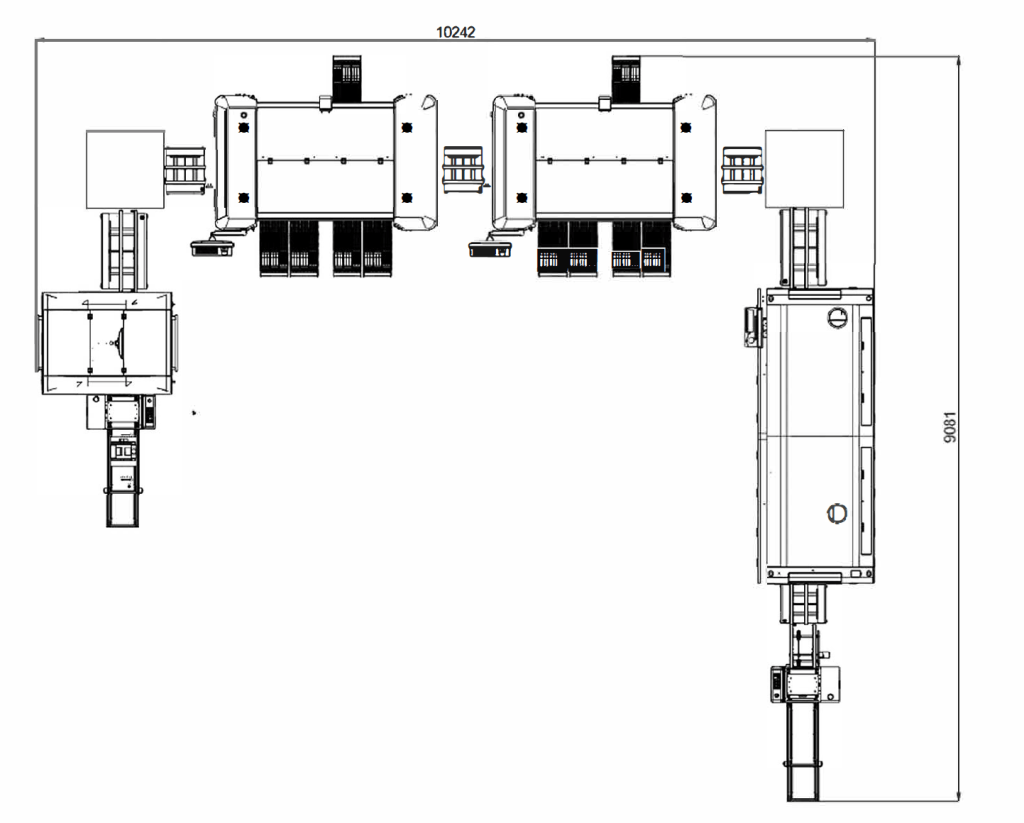

“We recently completed a project with a U.S. based PCB manufacturer that wanted to increase their production capacity,” said Pierre. “They wanted to add another SMT assembly line within their existing floorspace.”

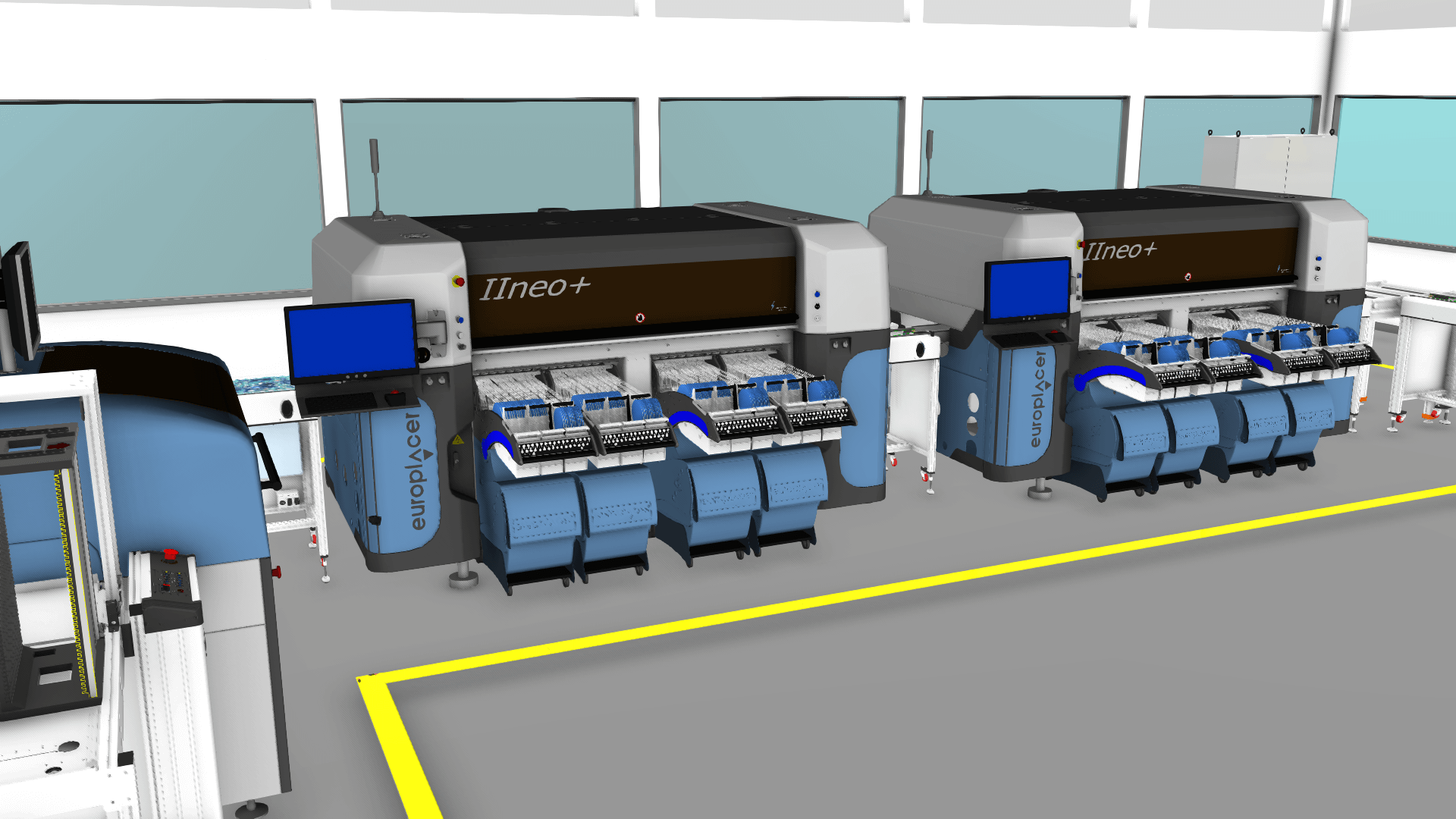

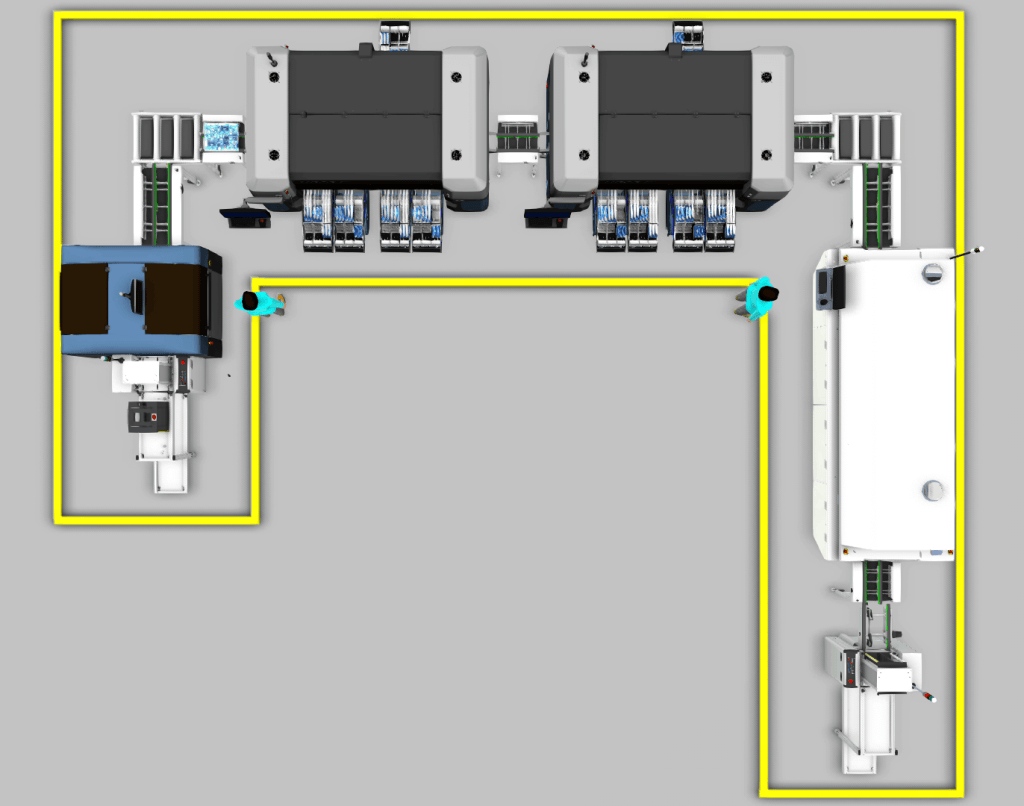

The assembly line included a PCB printer, two SMT pick-and-place machines, and a reflow oven; with a gate conveyor linking all the machines together.

“The challenge was to design a solution that met the customer’s production requirements and fit within the limited floor space,” said Pierre. “The space constraints made this project especially difficult.”

Europlacer’s proposal team used Visual Components to design different layout options and present them to the customer. After evaluating several options, they concluded that a U-shaped layout was the optimal configuration to meet the space and production requirements, and Europlacer was awarded the project.

“The use of Visual Components helped us win the project,” said Pierre. “The 3D simulation was very convincing for the customer and gave them confidence that our solution would meet the project’s requirements.”

The use of Visual Components helped us win the project. The 3D simulation was very convincing for the customer and gave them confidence that our solution would meet the project’s requirements.

Pierre Chatain, Product Marketing Manager

What’s Next

Just one year since implementing Visual Components, Europlacer is already seeing results. They’ve responded to dozens of layout requests and are noticing improvements in their response time and sales results.

“We’ve realized significant improvements in our sales process, in terms of both our efficiency and win rate,” said Pierre. “Our proposal response time has decreased from one day to less than one hour. That’s quite significant.”

Looking to the future, Europlacer plans to expand their use of 3D simulation to other applications.

“This tool is a perfect match for our request and we have discovered some very interesting additional features that we hope to apply as soon as possible,” said Pierre.

We’ve realized significant improvements in our sales process, in terms of both our efficiency and win rate. Our proposal response time has decreased from one day to less than one hour. That’s quite significant.

Pierre Chatain, Product Marketing Manager

Further reading

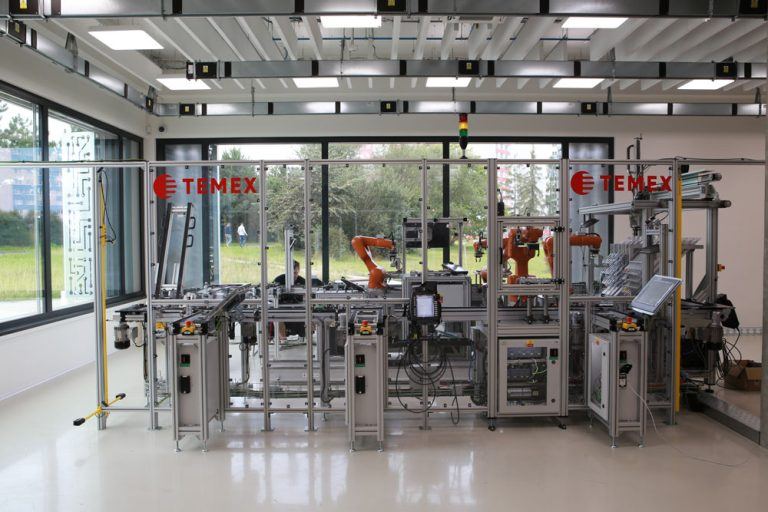

Smart Factory Project, a successful collaboration between TEMEX and VSB-Technical University of Ostrava

Read how TEMEX, a Czech-based manufacturing technology specialist, brought the Smart Factory project, a robust teaching tool at the VSB-Technical University of Ostrava, from concept to reality using Visual Components...

Elm Electrical Case Study

Elm Electrical chose Visual Components as their simulation tool. Find out why!