EROWA case study

Find out how EROWA saves resources and time with the Visual Components 3D Simulation tool.

Creating custom models

Erowa is a Swiss company that develops, produces and distributes modern manufacturing technology for the entire chip-cutting metal industry.

Erowa uses Visual Components’ 3D simulation tools and a custom-made library for visualizing production systems for their customers. To ease the adoption of the software, Erowa ordered their own custom model library from Visual Components ready-made.

“The modeling service provided by Visual Components was smooth and excellent. They were able to re-use our CAD designs to quickly produce exactly the models we wanted” says Justin Hulst, Head of Marketing Service at Erowa.

But Erowa is not stuck with just the models created at the beginning of the project. Visual Components also created the “Erowa Machine Wizard”, which allows Erowa to import models created in Cinema4D directly into Visual Components software.

There was nothing comparable to 3D simulation before.

Justin Hulst, Head of Marketing Service, Erowa

“Definitely possible to create more proposals”

In their own words, before adopting Visual Components tools, Erowa was either creating 2D layouts or spending days in creating and rendering 3D layouts.

Currently Erowa is capable of delivering still image 3D layouts of one robot family in half an hour and within four hours if animated movements are required. Visual Components 3D Simulation has definitely helped Erowa in creating more proposals to customers with less hours spent.

Saving resources, saving time

Compared to CAD modeling, creating layouts and showing robot movements is a lot easier with Visual Components.

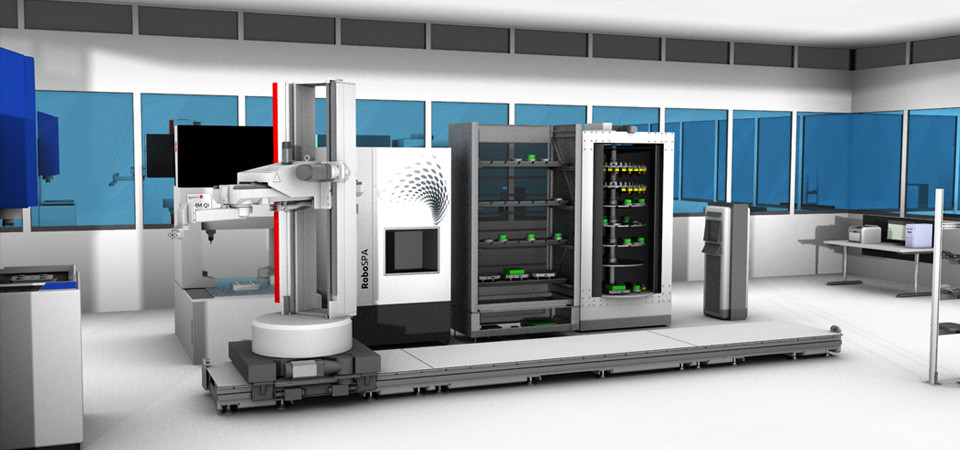

A sample manufacturing layout created with the components from the customized Erowa component library.

“It is possible that the customer requests 3 to 7 different versions just to get the feeling of how the robot really works, with no regard to technical details. 3D Simulation will save a lot of time in the presales phase”, Hulst explains.

Since they’ve’ started using Visual Components 3D Simulation, Erowa’s Layout designers have had much less back and forth change requests in the pre-sales phase.

If the sales engineer or customer wants to see the cell working, they simply create an animated 3D PDF with sped up movements supported by another animated 3D PDF where the movements and process times of the machines are adapted to real life.

In the future, Erowa is looking into various further possibilities of using 3D animated project descriptions. The library of EROWA Robots will be expanded as well.

Further reading

CNC-ing clearly now: boosting proposal speed and client understanding with Visual Components at Mazak UK

Mazak UK, part of a global leader in CNC machine tools manufacturing, faced significant operational challenges, particularly in conveying the complexities of their Palletech system using traditional 2D drawings. This...

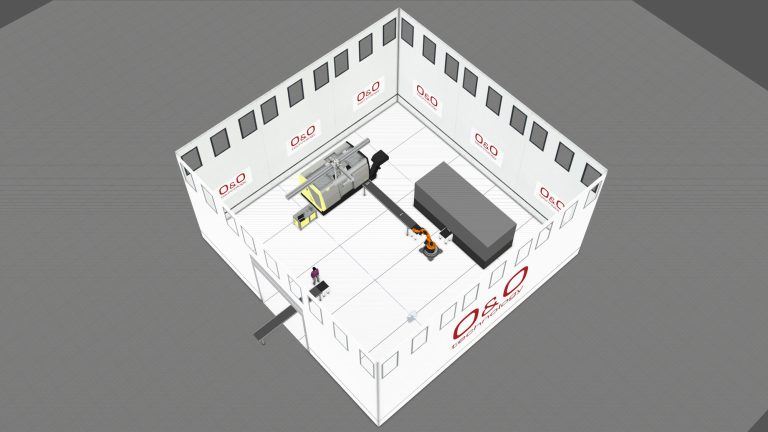

ONO Technology & SMB Technics Project Case Study: A Winning Partnership Lands a Key Project

Learn how SMB Technics and ONO Technology used Visual Components to design, optimize and validate the complete manufacturing line.

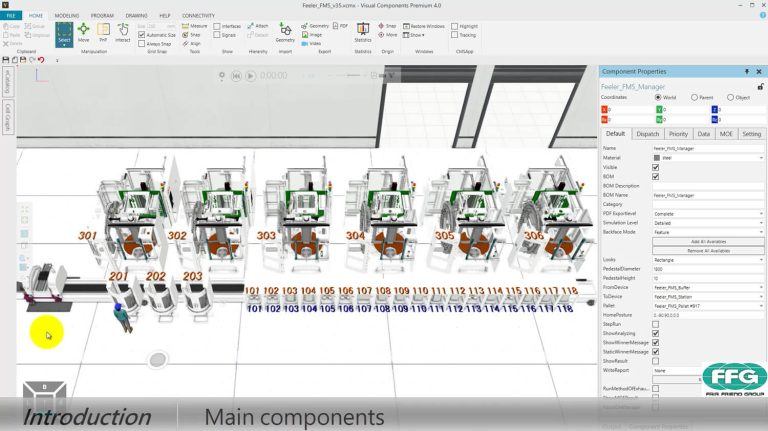

FFG Feeler – Optimizing Flexible Manufacturing Systems with Visual Components

Discover how FFG Feeler designed and optimized a Flexible Manufacturing System using Visual Components 4.0.