Using Visual Components to help Danish companies stay competitive in the global market

The Danish Technological Institute (DTI) is a leading provider of research and development services in a wide range of industries, through commercial projects or projects funded by the national Danish government or the EU. They work closely with customers to understand their specific needs and help them find innovative solutions through the use of cutting-edge technologies such as robotics and automation. Using Visual Components, DTI is able to help their customers visualize and understand the potential for innovation in their projects.

The role of manufacturing in shaping the future

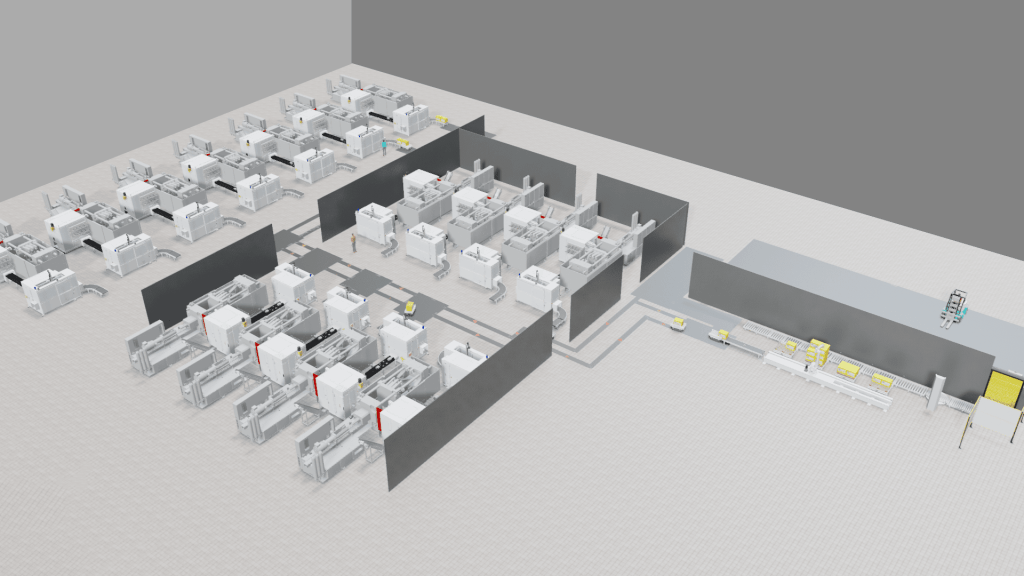

Awareness of the latest developments in manufacturing is essential for anyone interested in the future of the economy, society, and the world. The Danish Technological Institute (DTI) is well aware of the importance of keeping up with the latest developments. They provide technology-based services to companies and public organizations in Denmark. Their mission is to help Danish companies and organizations stay competitive in the global market by providing them with access to the latest technologies and knowledge. Their use of Visual Components is a prime example of this, as it has allowed DTI to create virtual layouts of their clients’ manufacturing facilities, helping them visualize the potential for automation, for example, and helping identify and resolve issues before they occur.

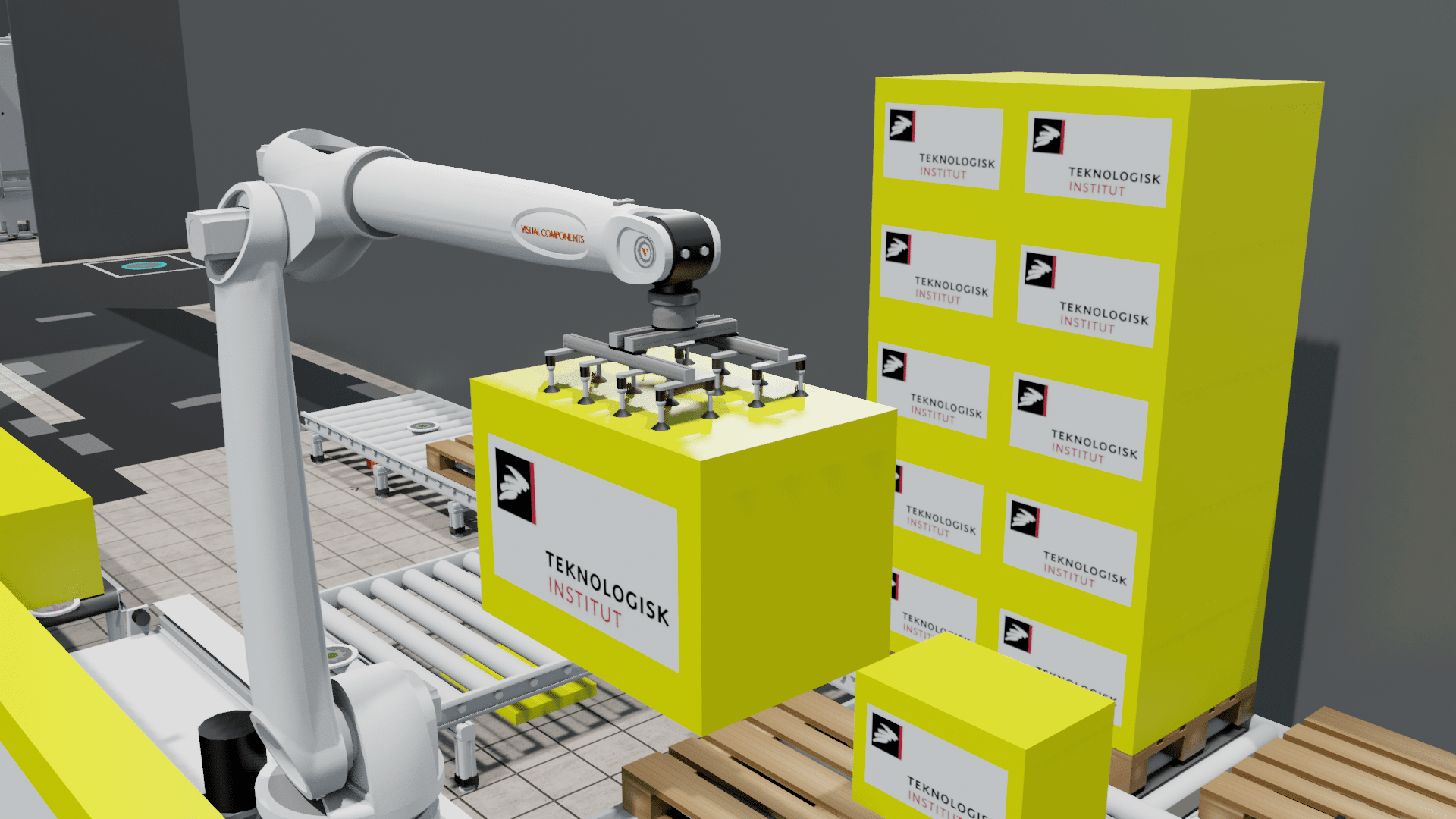

DTI’s research and innovation services are tailored to the specific needs of each client project. DTI is not supplying turnkey solutions but is more active in helping companies make their next step. DTI’s Senior Specialist, Martin Mølbach Olsen, recently worked on a project with a large manufacturer of box-packaging machinery for food products who were looking for ways to automate their manual palletizing process. The company had been manually palletizing boxes with packaging materials, but as their production volume increased, they were looking for ways to automate this process to keep up with demand.

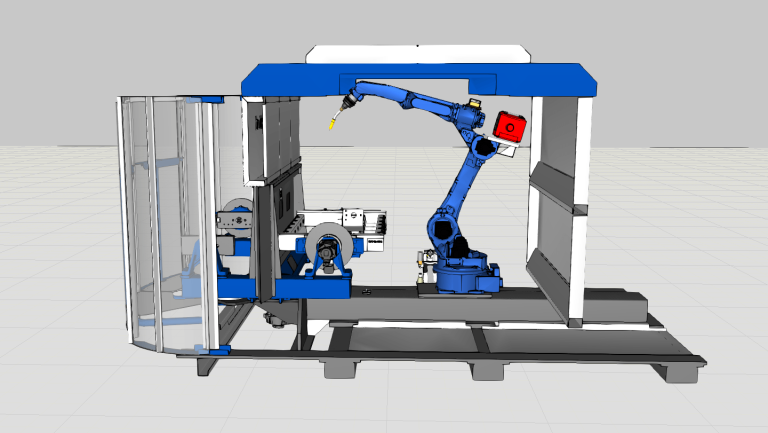

DTI used Visual Components to create a virtual layout of the company’s facility and show them how robots and other key equipment could automate the palettizing process. This allowed the company to visualize how the manufacturing layout would work in their specific environment and understand the benefits of automation as a means not only to help streamline their processes but also to provide material to help convince decision-makers within the company of the possibilities available.

“Visual Components helps our customers to visualize how an automation project could look and thereby help them make the right decisions.”

– Martin Mølbach Olsen, Senior Specialist, PhD Food and Production, DTI.

Visual Component’s eCatalog and VR features providing clarity

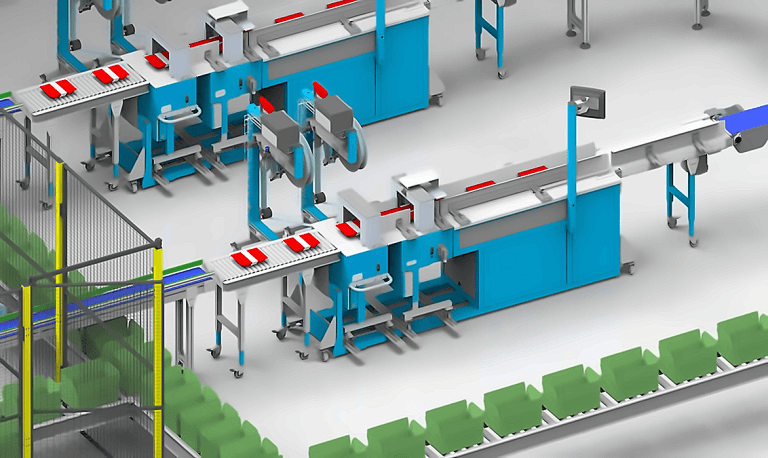

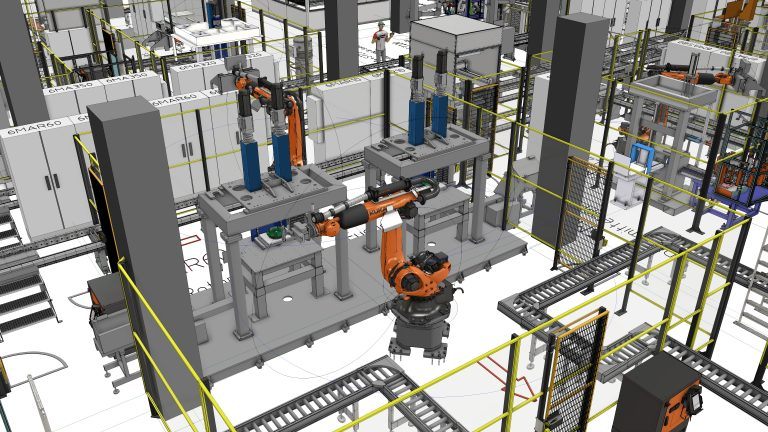

With simulation, in general, it’s easier to move the robot on the shop floor rather than make adjustments in real life. A 3D model gives perspective and helps the manufacturer make an informed decision. Buying the first robot or piece of equipment can be daunting, so Visual Components allows for greater understanding and helps the customer go ahead with a project. With DTI’s experience working with various customers across different industries, they often find that their clients can be unfamiliar with robots or mobile robots and how they can be used in their manufacturing processes. With Visual Components’ eCatalog, DTI could integrate robots and other key equipment into their existing systems and processes.

“Visual Components is a very comprehensive tool that comes with a lot of ready-to-use components, making the process of building a 3D simulation quite quick and easy. At the same time, it is also wonderful that it is possible to customize almost everything, giving the possibility to build customized components.”

– Martin Mølbach Olsen, Senior Specialist, PhD Production and Innovation, DTI

They also use the VR feature of Visual Components Experience for visualization and communication in virtual walkthroughs of the factory floor.

DTI’s role in helping Danish companies stay competitive in the global market

Using Visual Components has allowed DTI to provide their clients with a better understanding of how robots and other key pieces of equipment can be integrated into their existing systems and processes.

DTI will keep using Visual Components as a critical tool to assist Danish companies and organizations in staying competitive in the global market.

If you want to learn more about Visual Components and wish to choose the right tools and the best way forward with our software, please get in touch with us here.

Further reading

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design...

How EMIL SCHMID MASCHINENBAU designed a high-speed battery assembly plant with Visual Components

Facing the challenge of designing a fully automated battery assembly plant for a customer, EMIL SCHMID MASCHINENBAU turned to Visual Components. With 3D simulation and an extensive library of factory...

Maximizing efficiency and ROI from day 1: Duun Industrier pre-programs a welding robot cell with Visual Components OLP

Duun Industrier, a leading Norwegian heavy machinery manufacturer, installed the Nordics’ largest robotic welding station in 2013. Utilizing Visual Components for robot programming since 2014, they commissioned a new robot...