Case studies

Get inspired by our case studies and see how our powerful and user-friendly 3D manufacturing simulation and offline programming software is making an impact!

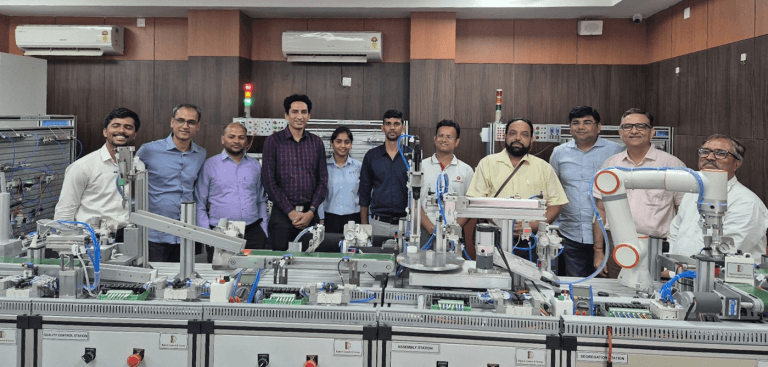

Visual Components brings digital twin technology to the classroom at IGTU

Indira Gandhi Technical University for Women (IGTU), one of India’s leading engineering institutions, is preparing its students for the future of smart manufacturing. With more than 300 women engineers trained…

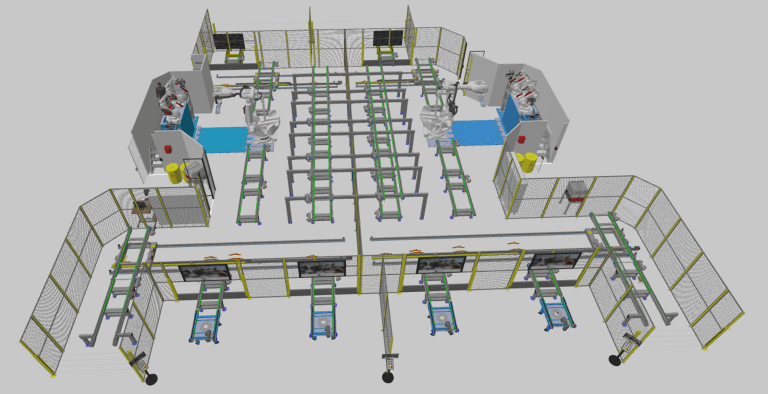

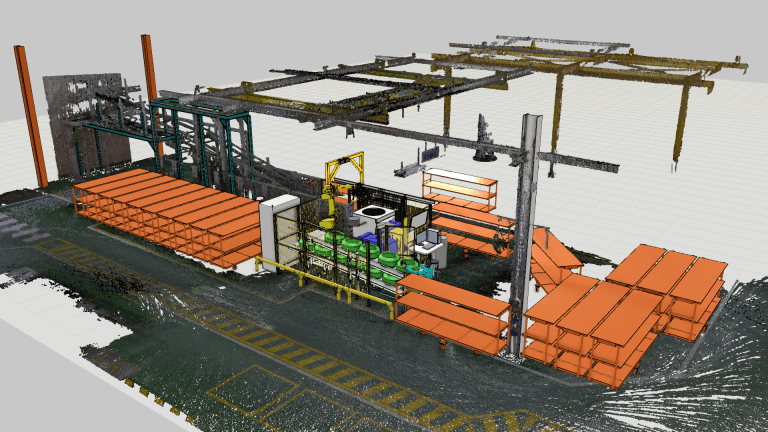

MSK Finland advances robot cell automation and intralogistics planning with Visual Components offline programming and manufacturing simulation

MSK Finland increases efficiency in both robot cell automation and intralogistics planning using Visual Components robot offline programming (OLP) and manufacturing simulation software. By creating and validating robot programs virtually,…

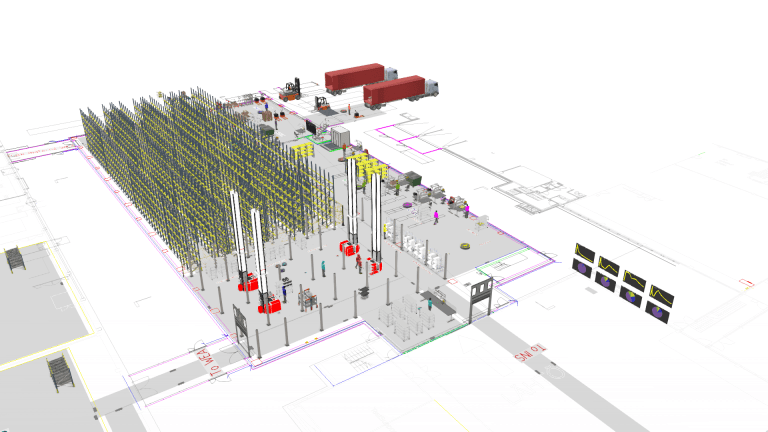

Vaisala optimized and validated its new logistics center with Visual Components

Vaisala recently built a new logistics center at its Vantaa headquarters to support growing production needs. Using Visual Components’ 3D simulation platform, the automation team modeled the entire facility to…

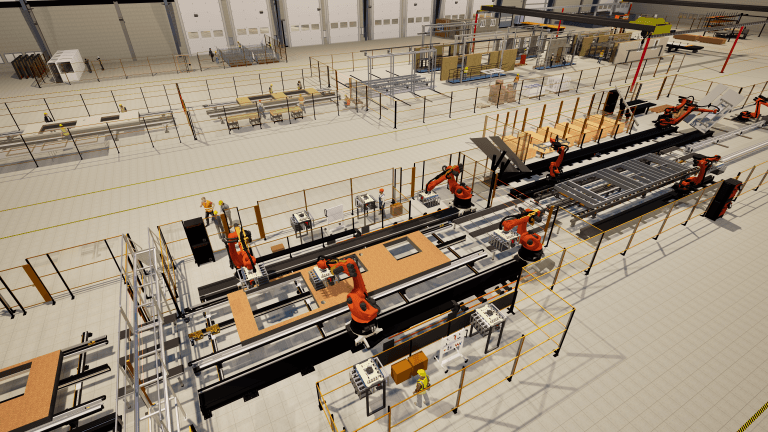

Wiksfors uses Visual Components to bring renovation into the factory era with RenoChain

Modernizing Sweden’s aging housing stock calls for a smarter approach. With Visual Components, Wiksfors developed RenoChain, a factory-based renovation concept that uses simulation to plan and prove a faster, more…

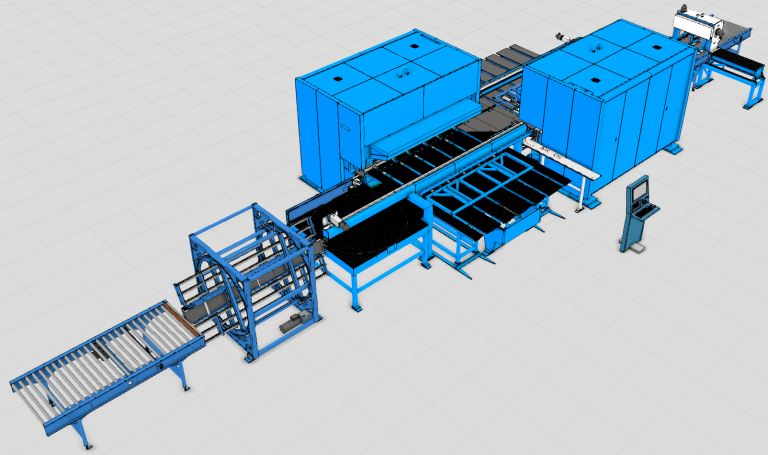

Pivatic streamlines sheet metal machine sales, software validation, and line optimization with Visual Components

Designing complete sheet-metal fabrication lines is no small task. Each project brings together machines, motion, and control systems into one smooth, custom-built process. With Visual Components, Pivatic has been able…

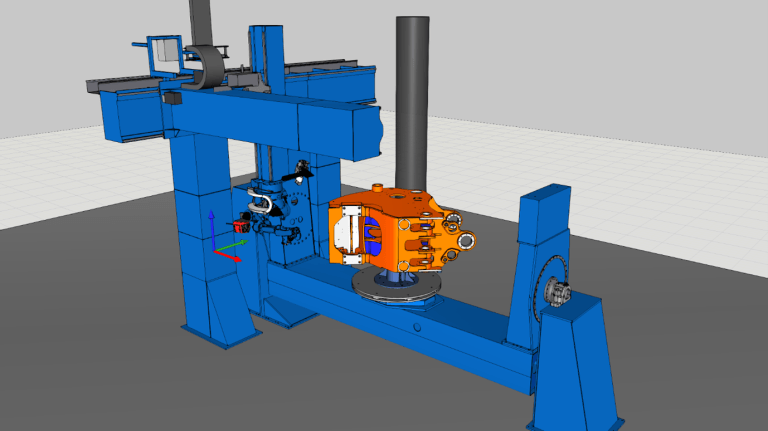

Sandvik boosts welding automation and reduces robot programming time with Visual Components OLP

Sandvik Mining manufactures heavy-duty underground loaders and trucks with complex, multi-pass welds. By adopting Visual Components offline programming software, Sandvik reduced robot programming time by more than half, improved weld…

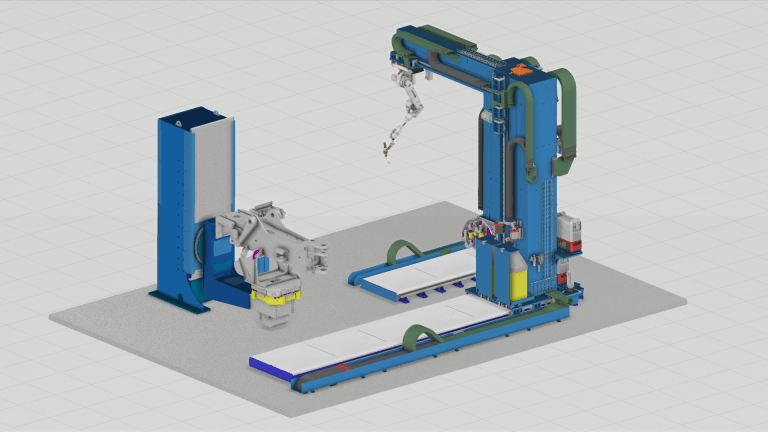

Ponsse drives efficiency in forest machine production with Visual Components OLP

Ponsse, a global leader in forest machine manufacturing, uses Visual Components robot offline programming (OLP) software to improve welding productivity, reduce robot programming time from 10 days to 1, and…

Michelin streamlines manufacturing planning with Visual Components 3D simulation

When different teams see different things, it’s hard to move forward. That was the challenge at Michelin’s plant in Thailand, where engineering drawings and CAD sketches couldn’t always get production,…

KOCH Steuerungstechnik sets new standards in modular plant engineering with Visual Components

KOCH Steuerungstechnik uses simulation as the backbone of their workflow, driving every project from start to finish. In their work with HANSWEBER to automate a brushing station, KOCH used Visual…

Elevating assembly planning for elevator button panels at KONE with 3D simulation

Planning a new assembly line for two product variants, KONE’s Northern Italy site needed to ensure smooth flow and minimal risk of defects. With Visual Components, they simulated and tested…

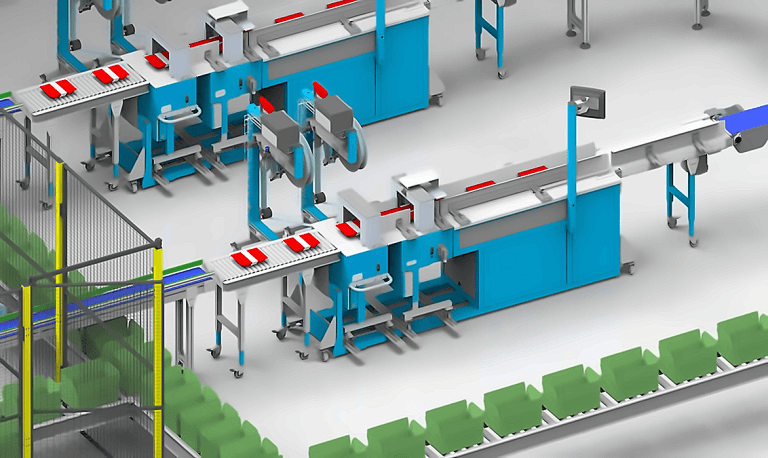

How Hollander Techniek designed an automated custom meal packaging system with Visual Components

When Uitgekookt set out to automate its meal packaging process, they needed a system that could handle custom orders with speed and precision. Hollander Techniek used Visual Components to design…

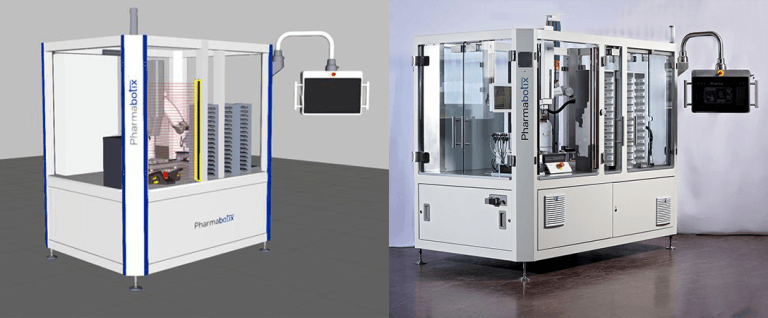

How Pharmabotix streamlines medical implant production with Visual Components

Since adopting Visual Components, Pharmabotix, a Swiss leader in robot-assisted automation for the pharmaceutical and medical technology industries, has enhanced how it designs and builds systems for producing textile implants….