Visual Components Simulations in NVIDIA Omniverse, a collaborative industrial simulation solution – Case: Lotus Technology

Collaboration among the three companies sets an example for more immersive simulations with life-like visuals and digital twins to plan manufacturing systems more efficiently.

The manufacturing industry has been evolving over the years with smarter production methods and new technologies. As we are witnessing a gradual shift from Industry 4.0 to Industry 5.0 digital age, with an emphasis on remote production management, the manufacturing industry needs solutions that could help them better collaborate with internal and external stakeholders and respond to any changes faster. With the Visual Components Connector for NVIDIA Omniverse, the manufacturing industry can access a unique virtual environment that not just offers production flow simulation but also the emulation of the system with life-like visuals and physical properties.

What does this cooperation mean for the manufacturing industry?

With the Visual Components Connector for NVIDIA Omniverse, manufacturers and system integrators are equipped with a holistic set of tools to conceptualize their production setups for digital twins, create virtual factories, and carry out simulation studies to measure and optimize performance. It will also reform how cross-functional teams across various locations can collaborate on projects by improving communications and expediting project delivery.

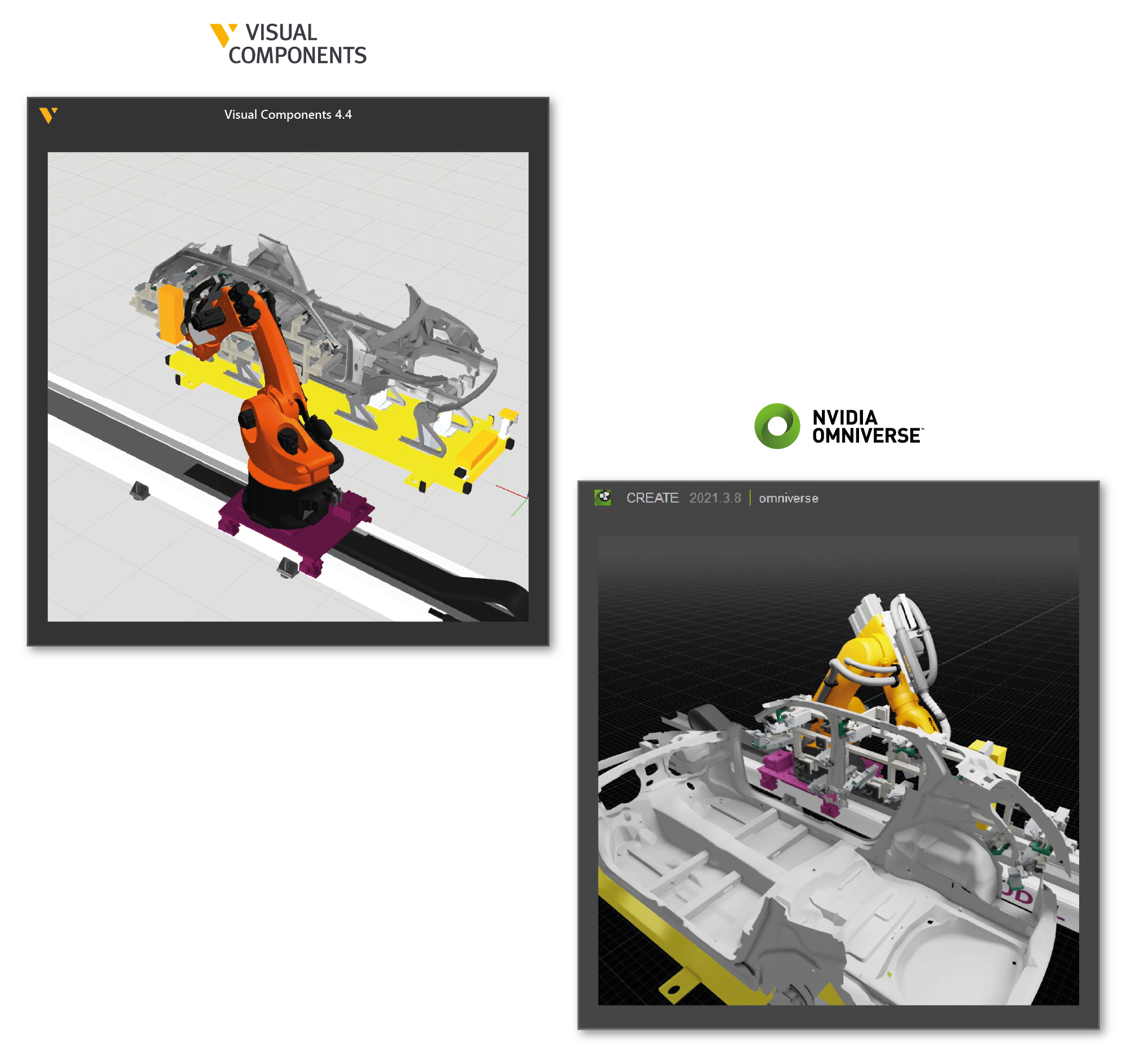

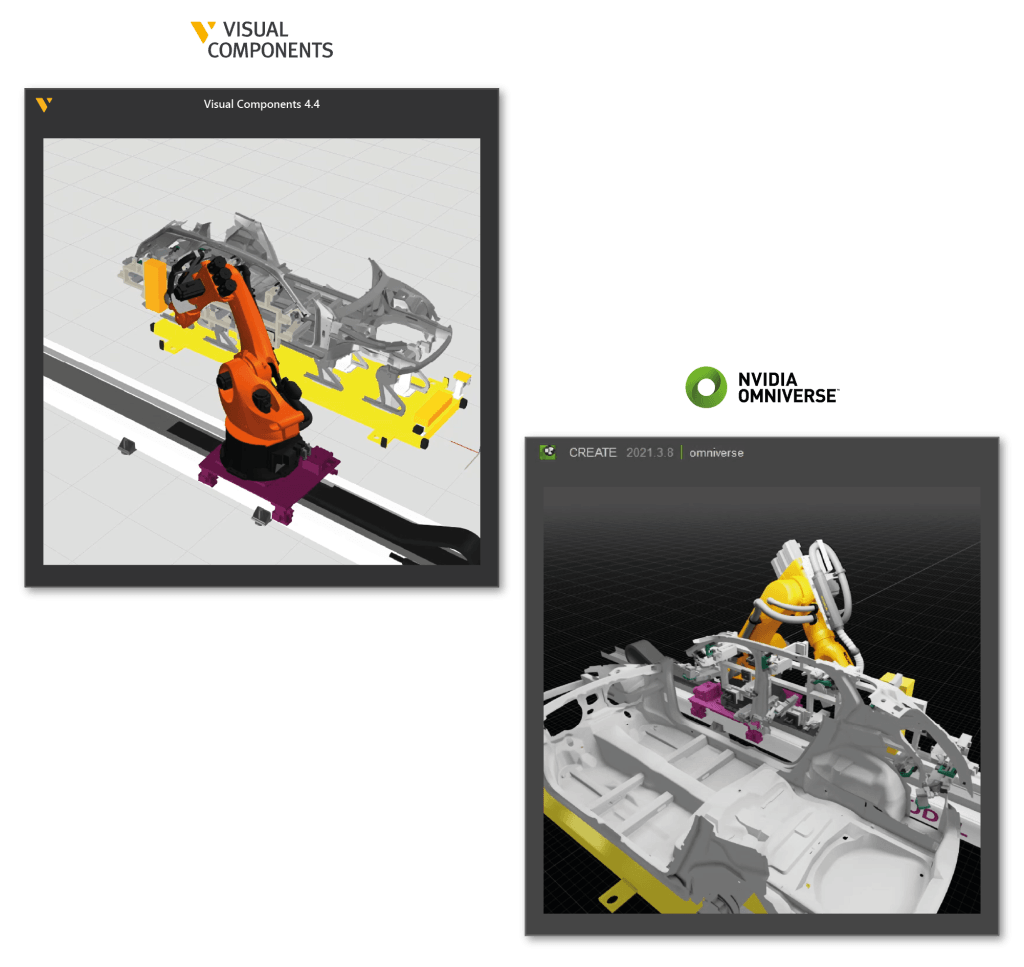

How does the Omniverse Connector work?

The Visual Components Omniverse Connector is a plugin to the platform that enables one-way communication from Visual Components to Omniverse. This means that any changes made to the layouts in Visual Components instantaneously translate into Omniverse – removing the need for constant export-import of files when iterations or changes are made.

Lotus Technology: Improving its tooling design and collaboration with Visual Components and Omniverse

Lotus, a top-of-the-line sports car brand currently owned by Chinese multinational automotive company Zhejiang Geely Holding Group Co., has already been using Visual Components simulation solutions to plan its production systems with easy-to-use layout configuration and robot programming features.

The Lotus-SD Digital factory team has achieved a 20% faster tooling design for the Lotus Lambda model with Visual Components. With Omniverse, the Lotus SD-Digital factory team has set its course towards huge opportunities created by the digitalization of automotive production starting with Lotus Technology.

The Lotus SD-Digital team has used Omniverse to offer a one-of-a-kind offering to their end customers — giving them virtual access to the production setups through a mobile app to let them experience orders while in production. These are some of the groundbreaking steps towards the creation of digital twins.

Here’s how the CEO of Visual Components, Mikko Urho, shared his thoughts about this cooperation:

“NVIDIA Omniverse is a state-of-the-art collaboration platform, and we’re delighted to be playing a significant role in the benefits it can offer Lotus Technology and its customers. For us, it’s a great opportunity to open new doors that we previously couldn’t while offering greater efficiencies and optimization opportunities with our simulation software.”

Mikko Urho, CEO Visual Components

Mike Geyer, industry product manager for manufacturing on the Omniverse team at NVIDIA, also shed some light on the potential of this cooperation:

“Visual Components joining the Omniverse ecosystem makes it easy for companies developing digital twins to quickly create models of their factories, warehouses, and production facilities. The combination of Visual Components’ intelligent content library with Omniverse’s simulation, AI, and collaboration capabilities creates an express lane for anyone looking to develop digital twins, and the work of Lotus Technology is a great example of this combined power.”

Mike Geyer – Industry Product Manager for Manufacturing on the Omniverse team at NVIDIA.

We’ll share more and more details on this in the next few weeks. Meanwhile, if you’re interested to find out more about NVIDIA Omniverse, check out the NVIDIA Omniverse website

Further reading

Visual Components partners with CADENAS to deliver millions of vendor-verified CAD models for 3D manufacturing simulation

Seamless access to verified CAD models At Visual Components, we strive to improve how our users plan, simulate,...

Introducing Visual Components 4.10 – Design beyond limits

Design beyond limits. That’s the promise of Visual Components 4.10. As manufacturing and robotics evolve, we continue to prioritize usability, ensuring that our tools not only keep up with industry...

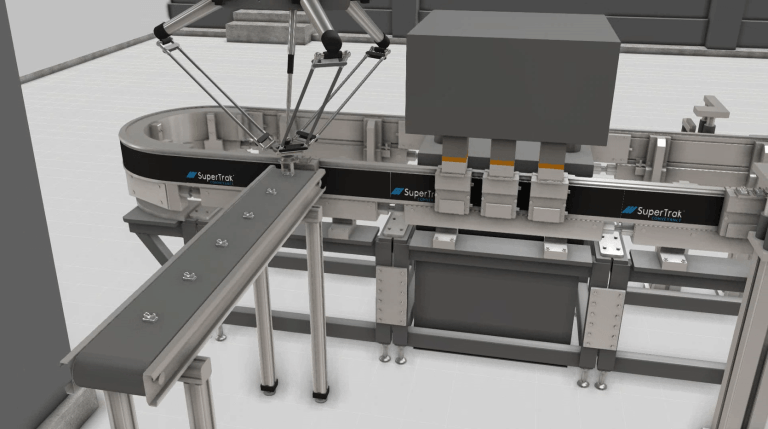

SuperTrak CONVEYANCE now in the Visual Components eCatalog

Visual Components’ eCatalog now features components from SuperTrak CONVEYANCE! SuperTrak CONVEYANCE™ is a magnetic conveyance platform that revolutionizes...