Under Pressure to Deliver: How to Achieve Speed and Accuracy

Two often-conflicting priorities that system integrators face with responding to proposals are speed and accuracy. How do you get both?

Two often-conflicting priorities that system integrators face with responding to proposals are speed and accuracy.

How do you get both?

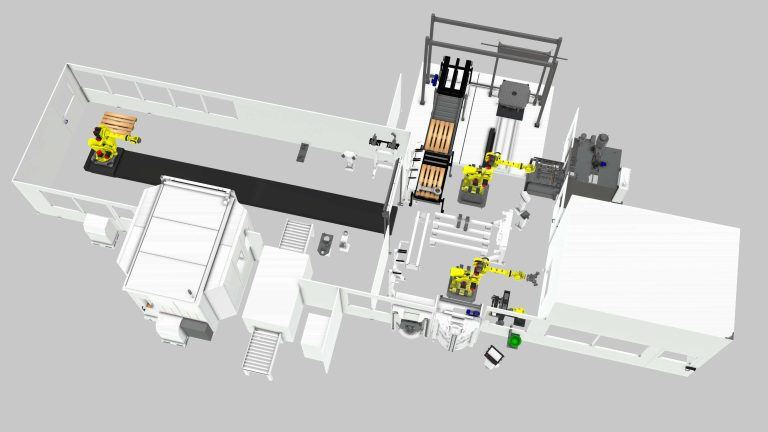

We’ve found from our many discussions with system integrators, that one of their most repetitive, error prone, and time-consuming tasks is preparing 2D drawings of their proposed layouts. This chore only becomes more error prone as they iterate through design and layout revisions.

Did you update the length of the gantry track?

Did you get a wider conveyor that fits with the new wrapping machine the customer requested?

Another area we found system integrators often make mistakes is with quoting production performance. The leading reason: Hubris. Sizing equipment based solely on experience may have worked before technology changed manufacturing, but it doesn’t work today.

When you’re preparing a high stakes proposal for a big project, you can’t rely on experience alone to backup your proposed solution. Nor can you use back of the envelope calculations, or even your expert Microsoft Excel skills. You need to be confident in your solution, to convince your customer – and your team – that your proposal will deliver on your budget, schedule, and performance promises.

CAD software is a great tool for designing manufacturing equipment, but not for designing manufacturing lines and solutions. Unlike 3D simulation software, it wasn’t developed specifically for manufacturing professionals who spend their days designing and optimizing manufacturing solutions.

It’s the same with using “hard-earned experience” and spreadsheets to size equipment and quote performance. They might help you get to the solution quicker, and serve as a good gut check – but are you willing to risk your company’s reputation on making a careless mistake?

3D factory simulation software is an effective tool for designing and testing manufacturing solutions because that’s what it was designed to do. You can build layouts, then simulate, validate, and visualize the processes. It’s accurate and it’s fast. And, when you’re happy with the results, it’s really as easy as hitting “print”.

In our next piece, we’ll talk about how you can use Visual Components to streamline your project proposal workflows.

Further reading

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...

An introduction to virtual commissioning

Virtual commissioning is reshaping the manufacturing landscape by employing computer simulations for testing and optimizing production systems before they're physically built. This approach not only simplifies the setup process and...

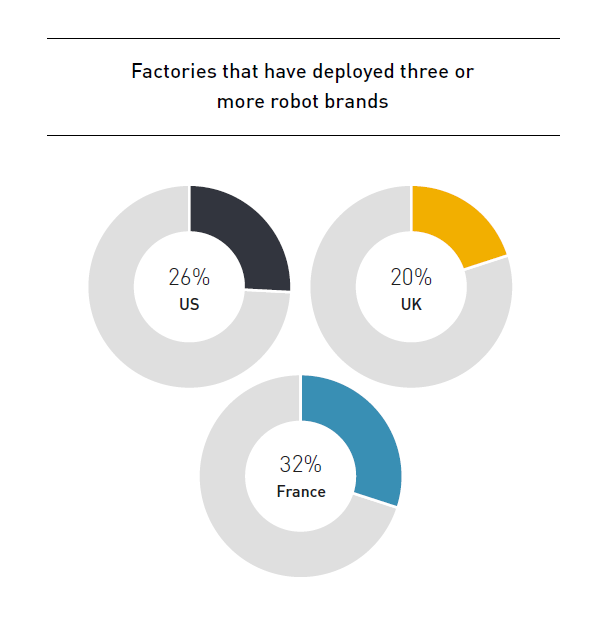

Are manufacturers really ready for the digital era? (survey results)

Legacy equipment and outdated practices can seem like relics from another age, especially as the world zooms ahead with digital innovations. Yet, they're more prevalent in the manufacturing sector than...