Simulation vs. Visualization – what’s the difference?

In this article, we’ll explain what simulation and visualization technologies are, why they’re helpful in the context of manufacturing, and how they complement each other.

We’re often asked about the differences between simulation and visualization. While these technologies are becoming increasingly popular by professionals in the manufacturing industry, we’ve noticed that there’s often some confusion between the concepts. Let’s see if we can help shed some light on this discussion!

In short, we define simulation as the production of data and visualization as the representation of data. While 3D visualization technology makes all of the elements look real, simulation technology makes them function as if they were real.

In this article, we’ll explain what simulation and visualization technologies are, why they’re helpful in the context of manufacturing, and how they complement each other.

We define simulation as the production of data and visualization as the representation of data.

Achieving real-world accuracy through simulation

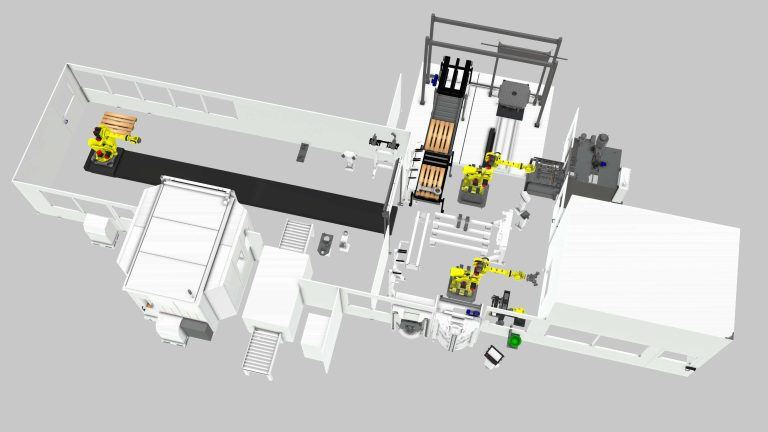

Simulation technology allows us to produce data. In the context of manufacturing, this data helps us to replicate and reproduce real-world operations of each of the elements present in a production line.

Thanks to simulation, we can emulate the different features, properties, and behaviors that manufacturing resources – including both equipment and labor forces – possess. It generates accurate information about their utilization, performance, and overall effect on production over time.

The data we obtain through simulation can also help us establish correlations between the resources and their yield, both individually and collectively. Moreover, we can test different combinations and interaction scenarios in the virtual world first. This way, we have much higher confidence that the manufacturing solutions we implement will function as designed.

Simplifying data through visualization

Visualization technology allows us to represent visually the data that we obtain through simulation. Instead of racking your brains trying to process raw simulation data, with this technology you can simplify complex information and turn it into a friendly 2D drawing, graph, high-quality picture, or even a 3D animation.

By providing numerical data in an easy-to-understand format, visualization allows everyone – regardless if they have a technical background – to interpret and analyze data efficiently. This in turn helps to speed up workflows and facilitates communication.

In brief, visualization technology makes simulation data accessible.

The power of simulation & visualization technologies combined

Visual Components’ 3D manufacturing simulation and visualization software uses both technologies to offer a complete solution that helps you to create marketing-grade content with engineering-grade accuracy. Thanks to its simplicity, high-level of precision, and ability to export project-ready deliverables – manufacturing professionals everywhere now have the power to design and communicate manufacturing solutions to teams, clients, and stakeholders.

Further reading

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...

An introduction to virtual commissioning

Virtual commissioning is reshaping the manufacturing landscape by employing computer simulations for testing and optimizing production systems before they're physically built. This approach not only simplifies the setup process and...

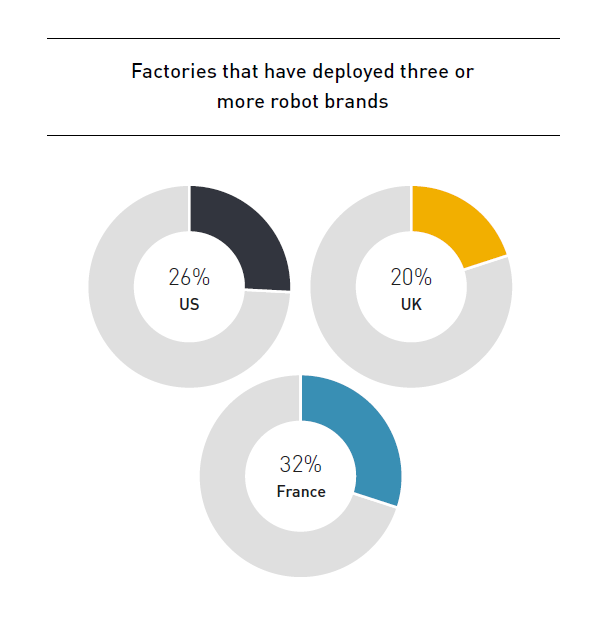

Are manufacturers really ready for the digital era? (survey results)

Legacy equipment and outdated practices can seem like relics from another age, especially as the world zooms ahead with digital innovations. Yet, they're more prevalent in the manufacturing sector than...