Simulation technology shaking the manufacturing industry

See the how the design and sales of production lines can be accelerated with the help of 3D simulation.

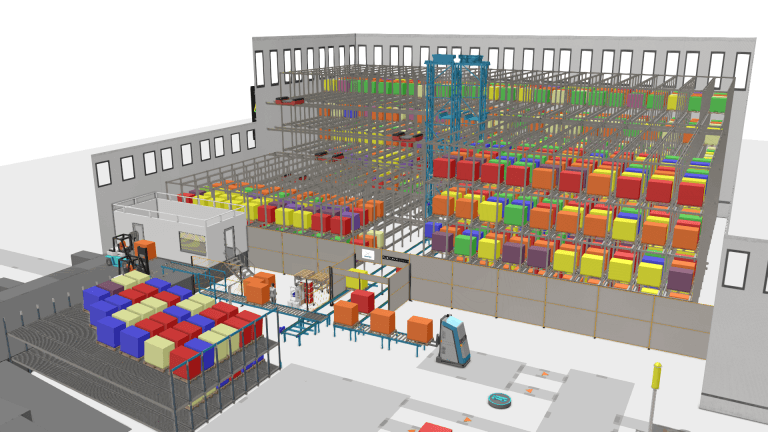

Towards more dynamic factory layouts

Selling a production line for a manufacturer is never a straightforward process. Some players in the production layout simulation business, however, are saying that now if never is the time to shake off the idea of slow, rigid processes and start profiting from the more dynamic layout planning solutions available.

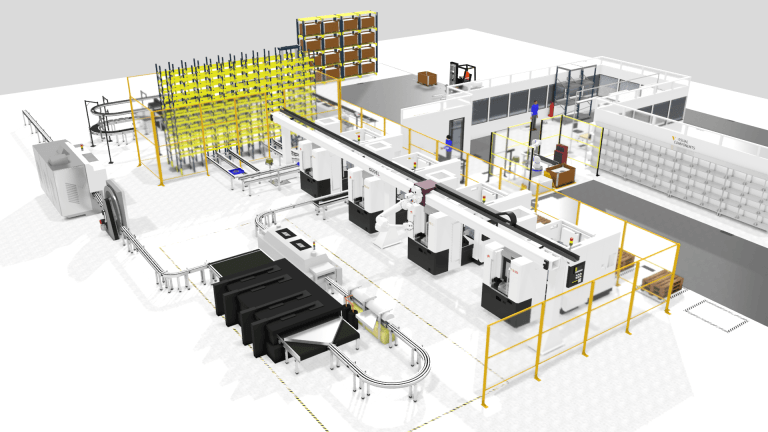

Companies of any size can benefit from 3D layout simulation

Production layout design used to be a game of only few players. “The way production lines were designed in the past was a bit of a mystery for many,” says Juha Renfors, CEO of Visual Components.

“We do not believe accurate, detailed production layout simulations should be the privilege of large companies that can afford to pay the high prices. Good simulation can be accessible and easy to use regardless of company size or simulation expertise.”

While, in the past, production layout design was in the hands of layout planning specialists, Visual Components created its solution for the mainstream. “Anyone can use our products,” says Renfors.

Companies have plenty to gain in their sales processes

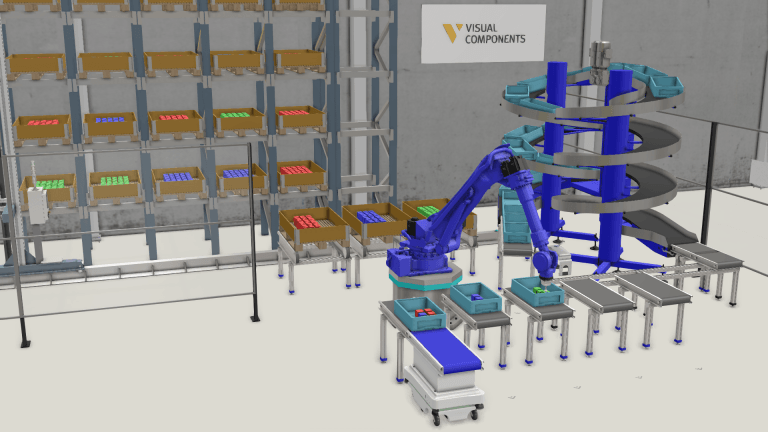

While 3D simulation is now made available for smaller businesses, also some expert companies like JOT Automation are substituting their 3D CAD software with Visual Components.

“At JOT Automation, they find that in, for example, their proposal processes their ideas can be presented better and any miscommunication can easily be avoided, using our solutions. Especially in an international business context,” says Juha Renfors.

JOT Automation, has been able to speed up their quotation process significantly: the time spent on a proposal is now on average seven times shorter than it was before.

Another company that has clearly seen the benefits of 3D simulation for production layout planning in their sales process is Fastems, an independent robot integrator with over 20 years of experience.

“With Visual Components, we went from making 50 proposals a year, to 200-250 proposals yearly. With our CAD software this simply would not have been possible.” Says Mika Laitinen, Sales Manager Robotics at Fastems.

With results like these, traditional 3D CAD companies should be worried. Even though, for example, Fastems still uses 3D CAD software to produce the final plan for manufacturing, many critical phases, such as reachability and collision studies are done with Visual Components.

3D simulation is a must in today’s business if you want to stay competitive. We could never go back to the old processes

Mika Laitinen, Robotics Sales Manager, Fastems

Manufacturing industry on the verge of transformation

It seems clear the mindset in the manufacturing industry is slowly changing. For Visual Components, the goal is clear: to make simulation the standard for production design.

“Companies like JOT Automation and Fastems are constantly finding new ways of using 3D simulation in their business,” Renfors says.

Being able to provide impressive savings in our customers’ time spent on proposal processes and providing a fast and easy tool for e.g. reachability studies, we have been able to create valuable partnerships with both larger and smaller companies and to establish a strong foothold on a previously CAD-driven industry.

It is taken as granted that the manufacturing industry is changing – the companies able to keep up with change are the ones likely to succeed.

Further reading

Optimizing production lines the smart way with simulation

Manufacturers are always looking for ways to improve, whether it’s increasing throughput, reducing bottlenecks, or making better use of resources. But optimizing production lines can get complicated without the right...

Smarter warehouse planning starts with simulation

How can businesses design warehouses that operate efficiently from day one while keeping labor costs and other expenses in check? The key is smart planning and validation with simulation tools...

Comprehensive guide to input data for 3D manufacturing simulation (examples included)

If you're new to 3D manufacturing simulation, you're in the right place. This comprehensive guide will help you understand the essential input data needed to create effective simulation models. Whether...