Managing by metrics – How to accelerate your sales with manufacturing simulation

See how manufacturing simulation can speed up the sales processes of systems integrators and sign up for a free webinar for more information.

Over the last several years, we’ve noticed many of our customers place a growing importance on using data to evaluate their performance, at all levels of their business. We’ve boarded the data train too and believe it’s a good thing; it holds us more accountable and helps us better understand how we can improve. Depending on your type of business and the function your team is performing, there might be any number of metrics that you’re being evaluated against. For system integrators, two of the key metrics we hear about most frequently are response time and win rate. In this article, we’ll tell you how manufacturing simulation can help you to improve on these metrics.

How does manufacturing simulation help your team create proposals faster?

On average, we see that it takes most systems integrators between several days to weeks to respond to RFQs. Depending on the scope and complexity of the project, each proposal can require input from several people, along with multiple rounds of revisions. And, when you finally get it to the prospect, and they inevitably come back with some “changes they’d like to see”, the whole process starts again.

For many system integrators, this is a costly and time-consuming cycle that they’re constantly trying to optimize. Their proposal response process is mired with slow internal processes, outdated tools, and inefficient workflows, resulting in duplicative work and unnecessary delays.

So, how can manufacturing simulation help? In short, it helps you to improve the speed and accuracy of your proposal response.

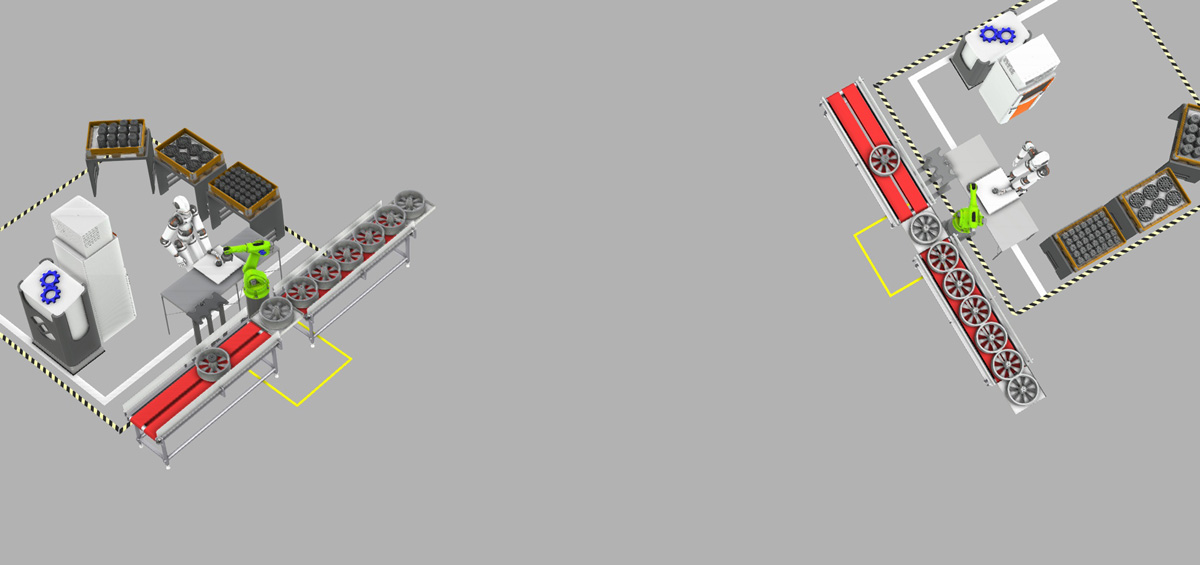

Technical Designers and Layout Planners can create layouts of the production line much faster, with the help of a ready-made component library and drag & drop tools, as opposed to working with time-consuming CAD software.

As the operating logic is built-in to the components (whether they are robots or conveyor belts or anything in between) that the Layout Planners use, Application Engineers can then use those same layouts to run feasibility studies and optimize the design of the proposed solutions. From here, it’s easy to export proposal ready content such as simulation videos, 2D drawings, and 3D PDFs, to integrate into your proposal or customer presentation.

And, when your prospect inevitably asks for those changes, you can be quick to respond. It’s even possible to have your sales team carry them out in the meeting room, right on their laptop.

Improving closing rates with manufacturing simulation

Even when the proposal is finally ready, the details and the visual representation often leave room for improvement. It’s not easy for prospects to see the big picture from an ensemble of spreadsheets, 2D drawings and CAD models and as a result, convincing them that your offer is the best of the bunch is tricky.

Manufacturing simulation can help with that too. Being able to create marketing grade content with engineering grade accuracy can help you differentiate your offering and give you an advantage over the competition. Manufacturing simulation helps you to create an easy-to-grasp, visual representation of the production line you’re designing. You can export an animated video or 3D PDF that illustrates your proposed solution, even in the context of your prospect’s facility. This makes it easier for them to see what they are buying and oftentimes provides crucial context and evidence that can’t be gleaned from spreadsheets, drawings, and explanation. We have lots of stories of how system integrators used manufacturing simulation to get an advantage in the proposal process and win projects.

Interested in hearing more about manufacturing simulation?

We would like to invite you to join our upcoming webinar this March 8, 12 p.m. EST on accelerating sales with manufacturing simulation. In the webinar, we’ll share with you how commercial manufacturing simulation software can help your team to respond to proposals faster, reduce mistakes, improve communication, and sell your vision to customers. You’ll learn why some of the leading system integrators use Visual Components to gain a competitive advantage in the proposal process, and get a live demonstration of how your proposal team can use Visual Components to respond to RFQs.

Further reading

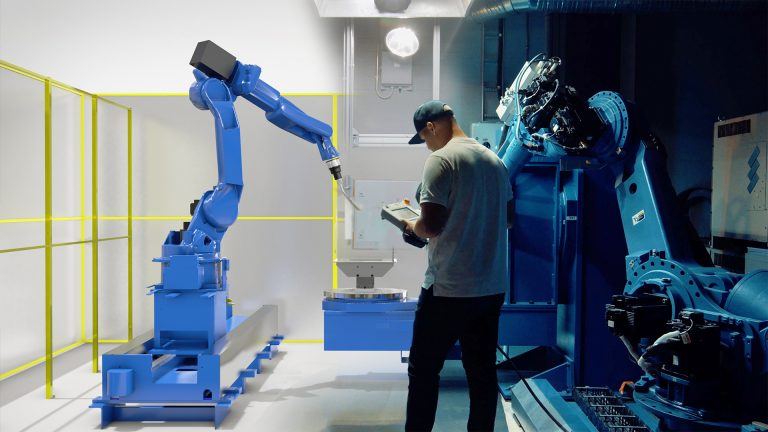

The future of automated manufacturing (and why humans still matter)

Automation in manufacturing has been evolving for decades, but its true impact isn’t in replacing people, it’s about making them more capable. We spoke with Mika Anttila, one of Visual...

Understanding digital twins in manufacturing

Digital twins go far beyond static models or simulations. They bridge the gap between virtual and physical systems, offering real-time insights and control. But with so many definitions floating around,...

Tackling the manufacturing skills shortage with simulation and robot offline programming

The manufacturing industry is grappling with a significant skills shortage, exacerbated by the pandemic and an aging workforce. According to The Manufacturing Institute, 78% of companies are concerned about this...