Considerations for CIOs in 2023: navigating sustainability, resilience, and human needs

In today’s rapidly changing manufacturing landscape, Chief Information Officers (CIOs) face the challenge of navigating cost pressures while balancing human needs, the supply chain, and new production strategies and technologies.

Sustainability has become increasingly important to consumers, and CIOs are emerging as key figures in driving these initiatives within their organizations. As strategic advisors, business partners, and business model enablers, they are responsible for identifying technology solutions that benefit both their employees and the environment.

Technology, such as simulation software, plays a vital role in helping organizations optimize their processes while reducing waste and carbon emissions. By implementing these technologies, CIOs can support employees in their growth and development, ensuring they can meet the expectations of an increasingly digitally-savvy workforce. Furthermore, CIOs must focus on making supply chains more resilient, adopting tools that improve production flexibility and agility, enabling lean or small batch production to suit available resources.

With the trend of reshoring operations also becoming more prevalent, CIOs must ensure that the right technology is in place to enable increased production capacity on-site. Simulation software can help scale to meet these demands and devise potential scenarios for incoming materials and components, allowing employees to test numerous eventualities before applying these learnings to the real factory floor.

By addressing these key challenges, CIOs can confidently navigate the evolving manufacturing industry and assume the lead in fostering technology innovation. In doing so, they can create a sustainable and efficient future for their organizations, meeting the needs of both their employees and customers while minimizing their impact on the environment.

Download our eBook to get an in-depth overview of the five top considerations for CIOs in manufacturing in 2023.

Further reading

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...

An introduction to virtual commissioning

Virtual commissioning is reshaping the manufacturing landscape by employing computer simulations for testing and optimizing production systems before they're physically built. This approach not only simplifies the setup process and...

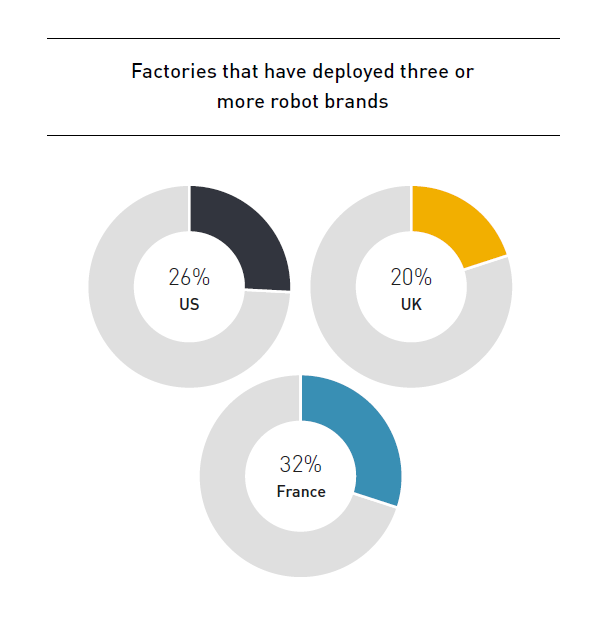

Are manufacturers really ready for the digital era? (survey results)

Legacy equipment and outdated practices can seem like relics from another age, especially as the world zooms ahead with digital innovations. Yet, they're more prevalent in the manufacturing sector than...