Benefits of using 3D manufacturing simulation software for planning RoboTape applications

3D manufacturing simulation software improves RoboTape planning and execution by providing detailed visualization, optimizing processes and robot movements and ensuring consistent quality. Discover how you can save time and costs, achieve smoother system integration and ensure optimal performance in automated manufacturing.

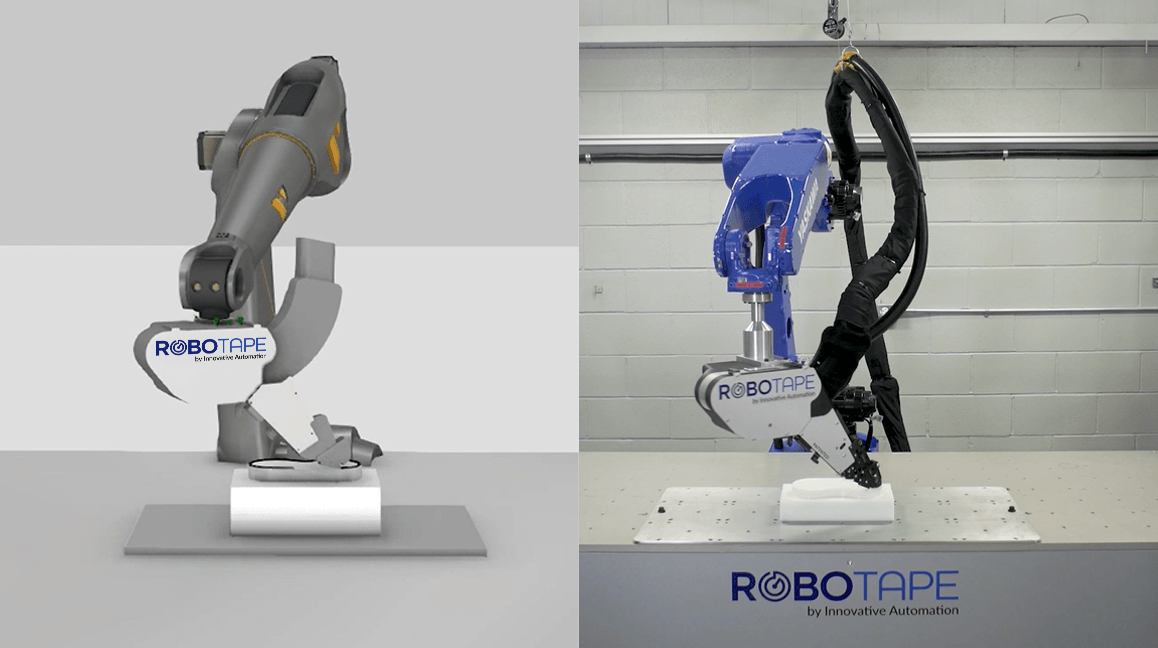

RoboTape Automated Tape Dispense Technology is significantly impacting industries like automotive and aerospace. The complete automated taping solution offers a more efficient way for handling tape applications, where precision meets performance.

As automation becomes increasingly important in manufacturing, simulation plays a vital role in planning these automated processes for success. Simulating before implementing allows you to identify potential issues and make necessary adjustments, leading to smoother system integration and optimal performance.

Benefits of 3D manufacturing simulation software

3D manufacturing simulation software offers several key advantages that are becoming increasingly helpful for the efficient planning and execution of RoboTape applications.

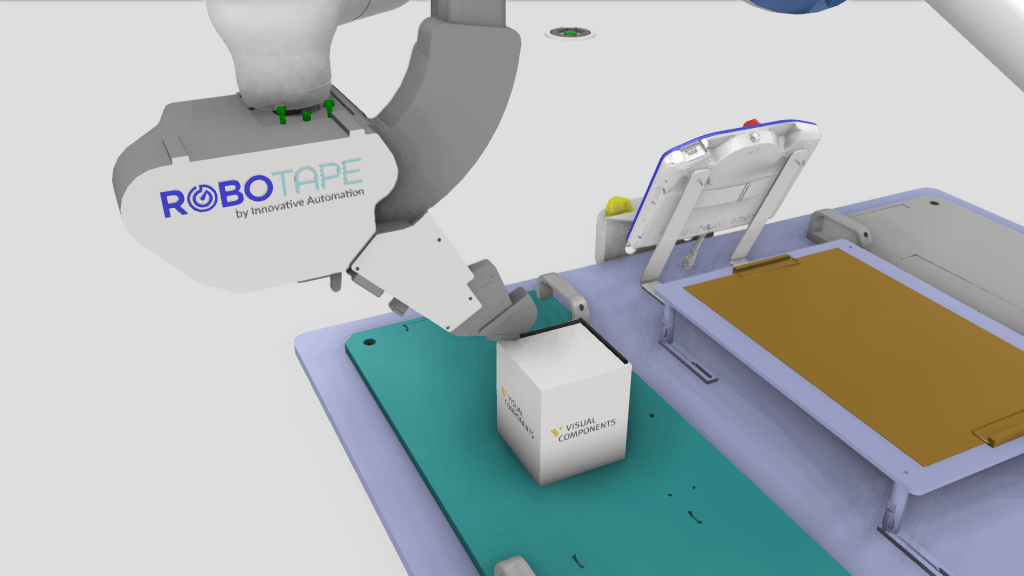

Firstly, it allows you to visualize how RoboTape integrates with your existing systems, enabling detailed planning and adjustments before actual implementation. This not only helps in avoiding expensive mistakes but also saves time and costs by identifying and resolving potential issues virtually.

Additionally, detailed simulations enhance communication with stakeholders. By providing a clear and comprehensive visual representation of the process, it becomes easier to explain plans and gain support from stakeholders, ensuring everyone is on the same page.

Read more: What is manufacturing simulation and how does it work?

Enhancing tape application processes

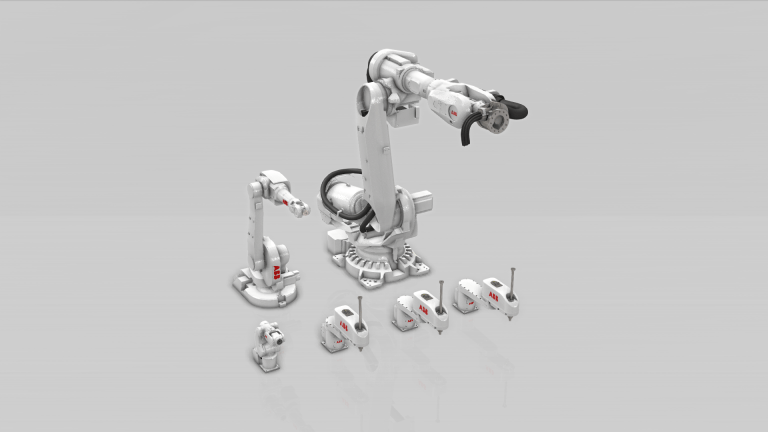

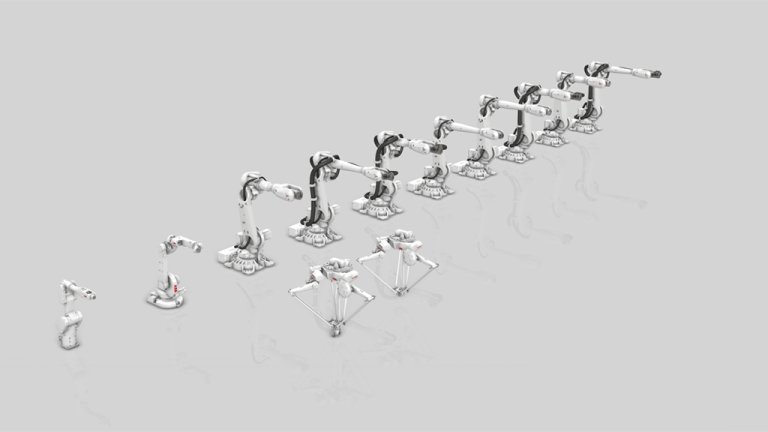

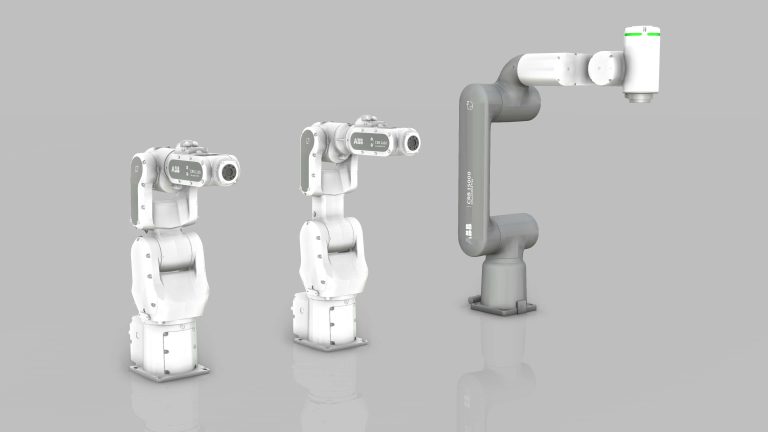

One of the key features of RoboTape components in the Visual Components eCatalog is the added capability to simulate automated tape application on complex surfaces. With the help of our automated robot path generation tool in our robot offline programming software, you can easily optimize robot arm movements and tape handling, ensuring precision and efficiency. Visual Components includes models and post processors of the top industrial robot brands like ABB, KUKA, Fanuc and many more, making it easy to find the right fit for your needs.

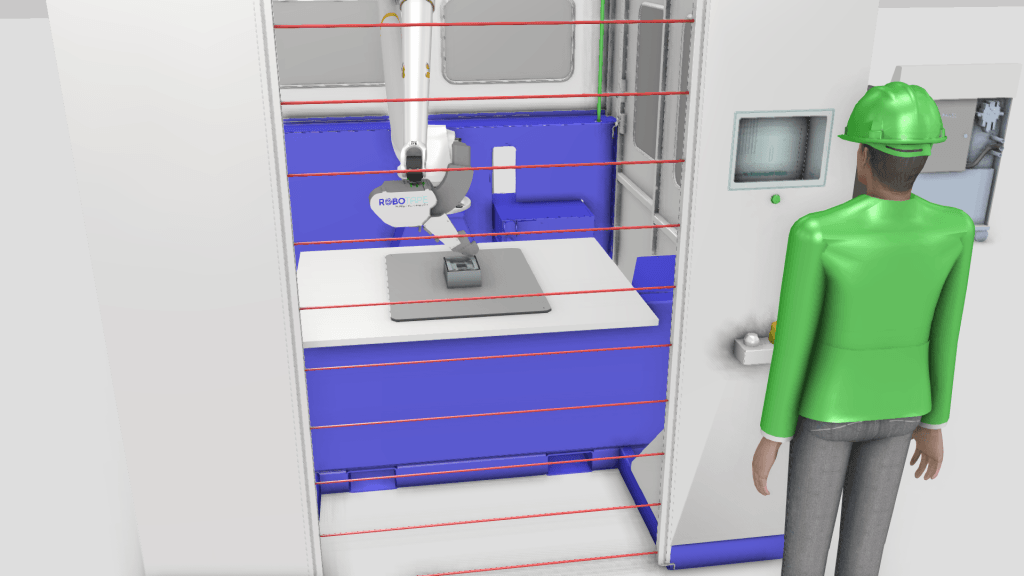

Moreover, our software allows for the simulation of multiple robot cells and their interaction within the larger manufacturing context. This provides a holistic view of the process and helps in optimizing the overall workflow. Integrating different control systems, such as PLCs, into the simulation ensures seamless coordination and operation. Virtual commissioning enables testing and debugging of the entire system in a simulated environment, ensuring everything works together seamlessly before actual implementation.

The software also visualizes how human staff interact with the automated process, highlighting potential areas for improvement and ensuring a safe and efficient work environment. This feature is crucial for identifying bottlenecks and ensuring the smooth integration of human and automated processes.

Improving quality control and efficiency

Another significant benefit of using 3D manufacturing simulation software is its ability to simulate real-time monitoring and adjustments. This feature ensures consistent quality and minimizes waste, as adjustments can be made virtually before actual production begins.

By testing processes virtually, manufacturers can avoid wasting materials and resources on physical testing and reduce costs. This virtual testing capability is a significant advantage, ensuring that the final physical implementation is already optimized for both quality and efficiency.

Conclusion

The benefits of using 3D manufacturing simulation software for planning RoboTape applications are clear. From visualization and error reduction to enhanced quality control and cost savings, simulation technology is becoming more and more essential.

At Visual Components, we are committed to providing the tools and expertise needed to leverage the full potential of automation in manufacturing. By embracing these advanced simulation tools, manufacturers can ensure precision, efficiency and competitiveness in their operations.

Explore RoboTape components in the eCatalog

Our eCatalog now features RoboTape components designed to meet the specific needs of your manufacturing process. Visit the Visual Components eCatalog to explore these RoboTape solutions and see how they can enhance your automated tape dispensing applications.

Further reading

We’ve Added New Components to our eCatalog! – December 2022

One of the biggest benefits of Visual Components is the eCatalog's vast library of pre-defined components. With 2,700+ components from more than 60 of the largest brands in industrial automation,...

We’ve Added New Components to our eCatalog! – August 2022

One of the biggest benefits of buying Visual Components is the eCatalog's vast library of pre-defined components which you’ll have immediate access to. With 2,700+ robots from more than 50...

We’ve Added New Components to our eCatalog! – September 2021

We’ve added 60 new components to our eCatalog. Check out the latest additions from ABB, ABI, Cobot Lift, Comau, DF Automation and Robotics, EasyRobotics, Fanuc, Haas, KUKA, Nachi, OnRobot, Panasonic,...