5 Reasons to Teach Visual Components in Your Class

Want to make your classes more enjoyable for your students? See how Visual Components 3D simulation software can help.

To teach or not to teach Visual Components? What a silly question.

Here are 5 reasons why you should look into Visual Components EDU PACK immediately.

1. Visit your factory virtually

Many students are completely new to Industry 4.0. Learning theory behind various processes can be challenging for students as they do not always see the processes in practice and do not see the big picture. But how can you show your students a factory without the need to go there in person? Have your students experience fully immersive simulation using the Interactive VR option in Visual Components.

Put VR glasses on and let your students walk through the layouts they created and interact with simulated equipment. Let them see the performance and relationship between different system parts, improve their knowledge and skills based on the simulation feedback and practice necessary skills without risking accidents to themselves.

Get familiar with robot and machine brands

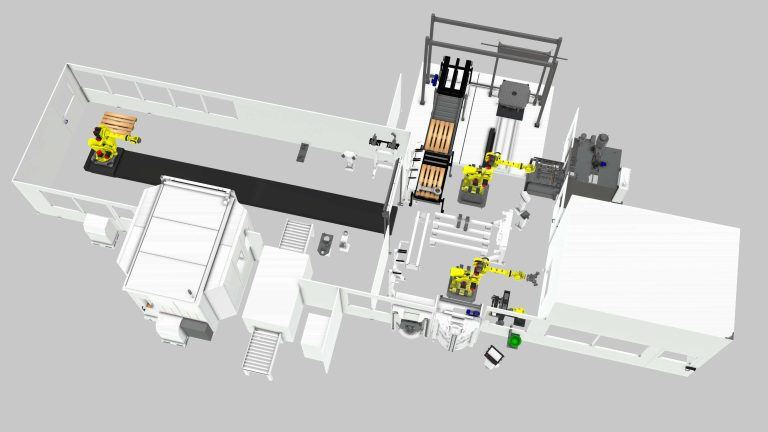

2. Get familiar with robot and machine brands

In Visual Components, students can familiarize themselves with various robot and machine brands while in the simulation tool. Choosing the equipment based on statistical data, they can build layouts from product feeding to delivery and understand the bottlenecks that the design might face and what modifications to make to the shop floor. Test different PLCs or other hardware using OPC UA as well as through WinMod and SIMIT connection.

Learning is no longer just abstract theoretical concepts.

3. Spark students’ creativity

Practice is key.

For students, designing one layout in the new software can already be challenging, let alone modifying and redesigning several scenarios. Often, the unnecessary complexity of the software prevents students to deploy new ideas and showcase them to other teammates.

The intuitive UI of Visual Components and the large component eCatalog allows students to quickly create different scenarios and provides a platform where students can exercise their creativity at designing various manufacturing systems.

4. Make group works easier

Group works are an integral part of student learning.

Learning to collaborate and work on assignments together prepares students for a real work-life where several people are working on the same project at the same time. To communicate the ideas efficiently, a good collaborative tool is needed. One of the important benefits of Visual Components is the possibility to live stream a simulation from Visual Components Premium to Visual Components Experience. Using the free VC Experience App on any device allows you to connect to simulation, view it, and collaborate.

After a recent collaboration with VR-ON, real 3D conferencing is now possible with Visual Components. The participants join a simulation session where they can discuss, modify, and finalize assignments in real–time from anywhere in the world.

5. Speed up onboarding with Learning Paths in Visual Components Academy

Often, the simulation software is used on the course to complete practical assignments. Students get an initial introduction to software but then, the learning continues on their own. We know this is a challenging process to get a good hold of the new software and therefore, we created Visual Components Academy. Students can select a learning path they wish to pursue and follow tutorials to develop the skills from beginner to advanced level.

With Visual Components Academy you can be certain that your students will be supported.

Further reading

Boosting production line efficiency: a guide on improving production output

Production efficiency is the cornerstone of success in manufacturing. It measures the effectiveness of resource utilization in the manufacturing process, aiming to maximize output while minimizing costs and waste. The...

An introduction to virtual commissioning

Virtual commissioning is reshaping the manufacturing landscape by employing computer simulations for testing and optimizing production systems before they're physically built. This approach not only simplifies the setup process and...

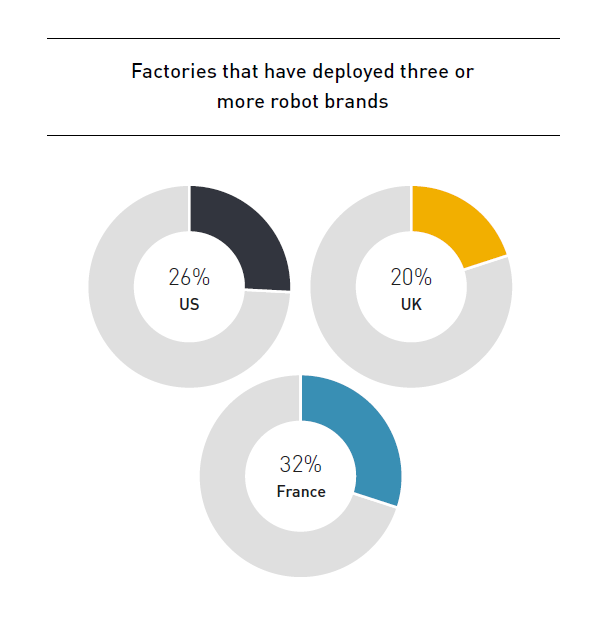

Are manufacturers really ready for the digital era? (survey results)

Legacy equipment and outdated practices can seem like relics from another age, especially as the world zooms ahead with digital innovations. Yet, they're more prevalent in the manufacturing sector than...