3D simulation in life sciences

Find out more about how 3D simulation can help you design and present laboratories.

The complex world of laboratory design

In the complex environment of a modern laboratory, it’s easy to get lost in designing the details. Creating an efficient laboratory for any life science application, especially in the pharmaceutical industry, requires a careful analysis of the workflows – how do you get the staff and equipment working together fluently in order to achieve the best possible results?

Designing the perfect lab can be both expensive and time-consuming, and in the end, creating a coherent solution is only the beginning – you also need to be able to convincingly demonstrate your solution to your customer.

Even though you as a vendor know that your solution will benefit the lab, the amount of work and planning required can seem daunting for the customer as new equipment and resources that modify the lab’s workflows are introduced. Therefore it’s important to visualize your solution as clear as possible so they can evaluate your proposal with all its benefits.

The problems of presenting lab designs

How then do you impress with your solution while putting it in a real world context? This problem of presenting lab automation designs has traditionally been solved using either CAD drawings, custom animated videos or mock-ups, or a combination of any of them to compliment the weaknesses of each presentation method. As an example, custom animated videos bring life to the static CAD drawings, but are expensive to make.

As the number of samples entering the laboratory can vary greatly by the hour, the designed system becomes easily over- or underutilized, as capacity is calculated based on averages. As a result, Turn-around-times (TAT’s) are more or less rough estimates and sometimes far from reality.

It’s clear that there should be a smarter way of designing and presenting plans for new laboratories. 3D simulation is a fantastic way to simultaneously impress and educate your customers.

Using 3D simulation in laboratory design

3D simulation allows to utilize existing CAD data and add motion and an impressive visual look to your proposals. Your customer can truly see the laboratory in action and distribute videos or 3D PDFs.

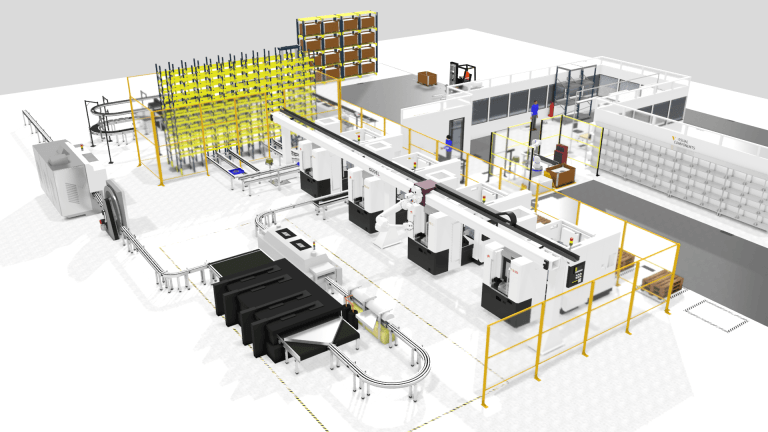

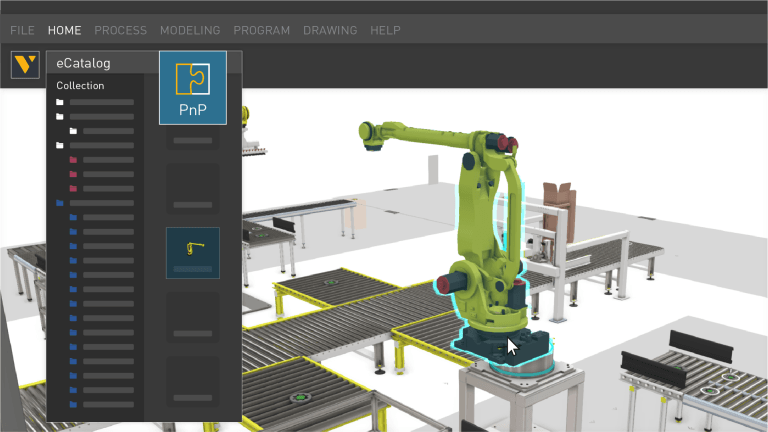

With 3D simulation, you can collaborate with your customer to easily create and modify different workflows within the laboratory in order to find the a balanced solution. Laboratory equipment can be easily dragged and dropped in order to create the perfect layout in order to easily be verify the whole plan.

You can also easily illustrate workflows inside the laboratory. Capacity calculations can be made based on peak times and throughput calculations. TAT’s can be calculated instead of estimated resulting in optimized buffer sizes and system utilization.

All in all, the use of 3D simulation enables you to effectively build your vision of the laboratory and present it as alab simulation to your customers.

Further reading

Comprehensive guide to input data for 3D manufacturing simulation (examples included)

If you're new to 3D manufacturing simulation, you're in the right place. This comprehensive guide will help you understand the essential input data needed to create effective simulation models. Whether...

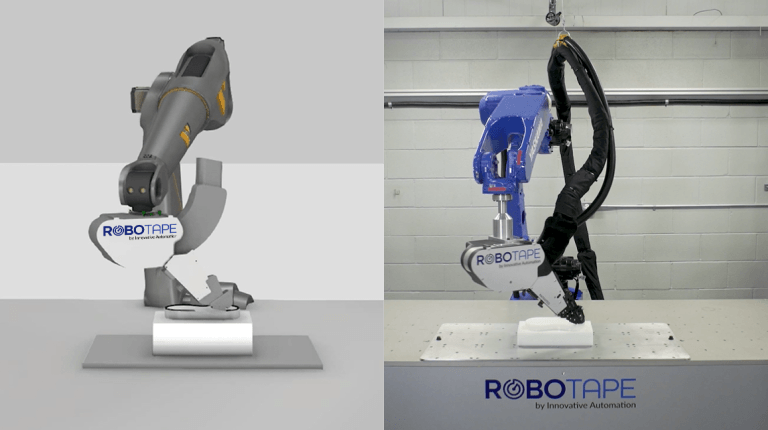

Benefits of using 3D manufacturing simulation software for planning RoboTape applications

3D manufacturing simulation software improves RoboTape planning and execution by providing detailed visualization, optimizing processes and robot movements and ensuring consistent quality. Discover how you can save time and costs,...

Leveraging simulation for factory layout design

Explore how discrete event simulation and digital twin technology play crucial roles during the ideation and planning phases of factory layout design. Our software simplifies the design process, providing accurate...