3D Production Simulation: A Complete Overview

This article introduces the 3D production simulation, outlines the different types and methods of simulation, and explains the benefits of production simulation.

Purchasing manufacturing machinery and laying out production lines and warehouses is not one of the easiest jobs in the world. Decisions made during the planning stages will establish and constrain costs and capacities for years to come. Get it wrong and you cede the advantage to competitors but get it right and your business will blossom.

So how do you determine what equipment to buy and layout to use? By using a 3D production simulation.

In this article, you’ll learn about,

- The importance of production simulation

- Different ways to simulate production environments

- 2D vs 3D production simulation

- Types of simulation

- A closer look at Discrete Event Simulation (DES)

- How 3D simulation addresses production challenges

- How users benefit from 3D production simulation

Simulation is a powerful way of reducing risk by evaluating multiple alternatives. 3D production simulation tools, like those from Visual Components, let manufacturers experiment with alternative layouts and configurations. They make it possible to quantify the results of variability and uncertainty. They give insights into improvement opportunities, and they are powerful tools for communicating ideas and proposals. Additionally, these tools help to ease the decision-making with valid arguments and improved forecasting that streamline the major planning hurdles.

The idea of simulating manufacturing operations is not new, but only recently has enough computing power been available to make it practical, accurate, and effective. This article provides an introduction to 3D production simulation for those not familiar with it, outlines the different types of simulation, and explains the benefits that result from using it.

The importance of production simulation

Manufacturing operations are often very complex. In many facilities work arrives at a machine in a batch. Let’s assume that in this case, the machine processes one item at a time. When the whole batch has been processed it moves on to the next machine. Now, multiply this by a dozen steps in the manufacturing process and fifty batches of different products that need different combinations of operations making their way through the same factory.

Understanding the various workflows and queues is hard, figuring out where to make changes that will lower costs or increase capacity is even more challenging. This is where production simulation can help to highlight the bottlenecks and streamline the day-to-day operations.

Different ways to simulate production environments

Simulation entails building a model to replicate the time-dependent behavior of the production environment. This could be done with wooden blocks and cardboard. It’s often attempted with spreadsheets, or it can be done with software developed specifically for the task. Once built, the model is run over as few or as many production cycles as needed to answer the question being asked.

Physical mock-ups can be an effective way to gain an understanding of a layout or workflows at a particular machine but they’re rapidly overwhelmed by the complexity and looking forward more than a few cycles is impractical.

Spreadsheets are better for looking at the impact of variability and for modeling multi-step operations. However, they have a bunch of limitations.

Some of the downsides include:

- They can quickly become extremely complex.

- It’s impossible to incorporate every variable and sequence step for every product like physical features, for instance, the flow of products between different processes, spacing issues, manual actions between the process, and so forth. These issues are commonly observed in the manufacturing environment and many times, they are spotted as the actual bottlenecks in the production processes.

- It’s very difficult to explain conclusions drawn from spreadsheet modeling.

Simulation software uses graphics and animations to display the results of the intensive mathematics going on “under the hood.” This lets the user see what will happen, which has more impact than trawling through rows and columns of results.

Production simulation starts by building a model of the manufacturing operation, line, cell, or factory. This needs to reflect reality as closely as possible: any errors will reduce the accuracy and value of the results. When simulating an existing operation validating model accuracy is straightforward: enter or load a recent production schedule or machine characteristics and see how closely simulation results match those actually achieved.

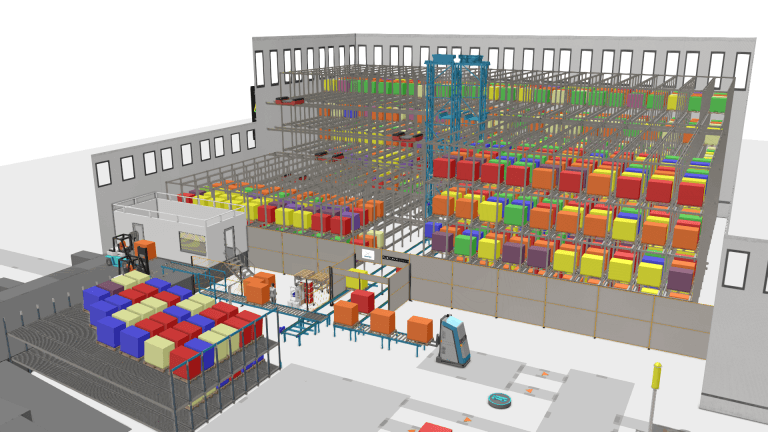

Where things get harder is building a model of a layout or operation that doesn’t yet exist. This is something that might be done to assess material flow in an as yet unbuilt warehouse or packaging hall. Under such conditions, it’s very important to test assumptions and gather as much data as possible to ensure accuracy. In such cases, even though the model cannot be verified against real data, different scenarios or approaches can still be compared with each other to get the ‘most likely best solution’.

2D vs 3D production simulation

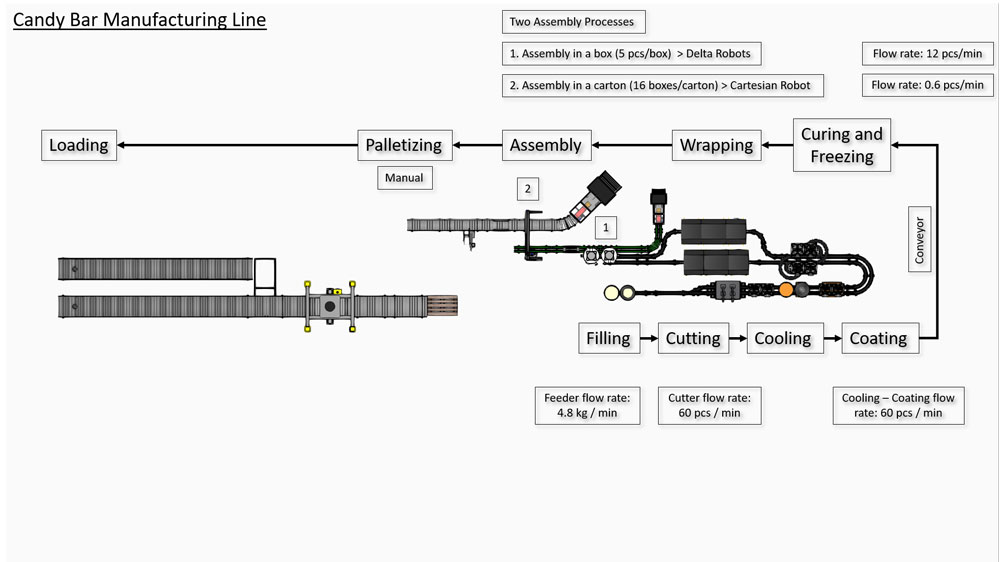

Early simulation tools provided a 2D view of the layout or area being modeled. Processes were represented as blocks with predefined process times and material throughput was calculated based on these cycle times.

While a huge advance on spreadsheet modeling, the 2D layout was only a crude approximation of the physical implementation. This made material flows difficult to follow or unravel and inventory quantities hard to see. In addition, unintuitive graphics limited the ability of the model to persuade an audience of the merits of a proposal not to forget that the missing simulation of the resources like humans, vehicles, etc. And perhaps of greatest importance, this hindered the ability of those using the model to make quick and effective investment decisions.

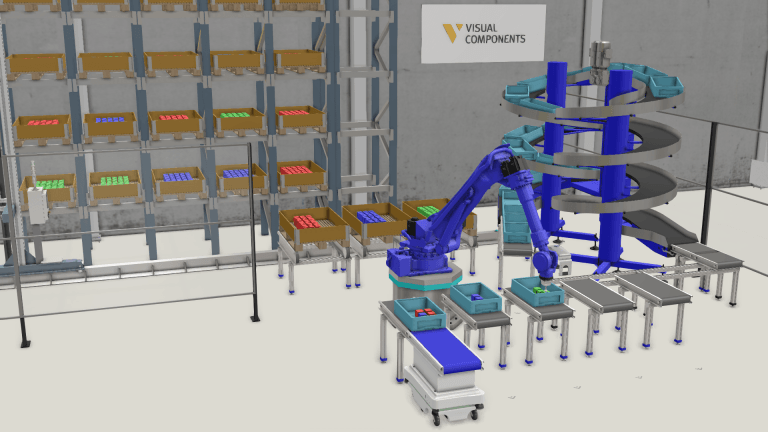

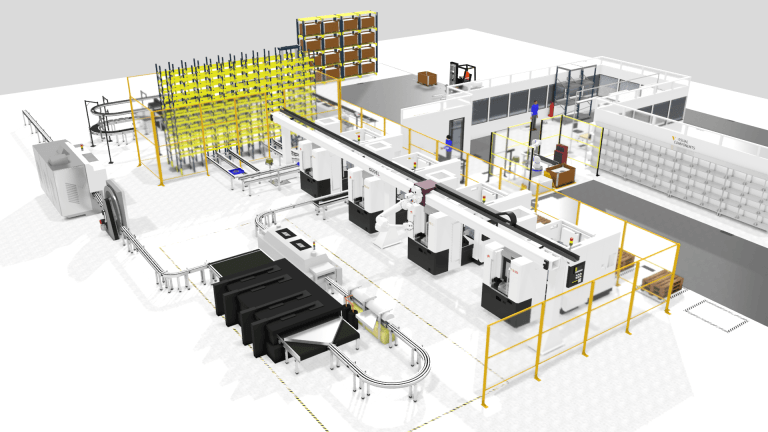

As the name suggests, 3D simulation tools provide a more accurate and even lifelike representation of the subject of the model. 3D makes it possible to see inventory rising and falling and material flows are clear. The simulation that is modeled needs a minimal explanation for others to understand what it’s telling them.

Visual Components simulations are set up with easy and simple-to-use workflow and ready-to-use 3D models from a library. Plug-and-play features enable faster layout design and the visual process modeling features allow users to manage the process flows without complex programming.

Pre-defined simulation behaviors in the components allow easier adaptation to the technology by users of all skill levels. At the same time, open architecture and simple UI allow easier customization in situations where there is a need to simulate special use cases.

Types of simulation

Simulation is performed in different ways, depending on the application and question being asked. Heat transfer, traffic flow, and industrial process control can all be simulated but need different tools to do so.

The main types of simulation are:

- Discrete event simulation

- Monte Carlo analysis

- Continuous simulation

- Agent-based simulation

The technique most often employed for modeling manufacturing operations is Discrete event simulation. This describes a process as a sequential series of events with a focus on what the event does, at what time it occurs, and how does it affect the other events.

Monte Carlo analysis applies probabilities to the computational algorithms that turn inputs into outputs. This lets the model builder determine the most likely outcomes for a given set of input conditions.

Continuous simulation is used in flow processes. Feedback control in pumping systems is a technical example but it could also be used to model business processes.

Agent-based simulation models how different parts of a system interact with each other. It could be thought of as, “If X happens, then Y will result” inside an agent. An agent-based simulation is used in situations where there are many independent agents. Healthcare provides a lot of examples, as does logistics.

A closer look at Discrete Event Simulation (DES)

An event is prescheduled moment in time when something happens in simulation and a model is composed of a series of sequential events. Each event is defined as an instantaneous change of state, rather than taking a finite length of time and an event can trigger or reschedule other events. This simplifies the model by avoiding the need to simulate repeating or dynamic activities between events that have no bearing on the model results.

In the model “entities” flow through the process and are acted on by events. In a manufacturing discrete event simulation, entities could be batches of work. Each batch or entity can have a different size and need different processing steps or events. There is no need to model how long it takes to mill or turn each component of the batch. Instead, the event instantaneously changes the condition of the entity from, for example, not machined to machined. However, a record is maintained of how long it would take to machine the batch thus creating an event when machining is done.

Manufacturing takes many forms with batch production being just one. Discrete event simulation is applicable to all types of manufacturing from single-piece production to mixed and continuous production processes.

Visual Components introduced process modeling features in November 2019 with their version 4.2 release which is based on Discrete Event Simulation (DES). In DES, every event happens at a certain state of time and simulation records the events and reacts accordingly.

Challenges that benefit from 3D production simulation

In manufacturing, there are two principal reasons for using discrete-event simulation: to assess how an operation will respond to changes in input or operating conditions and to reduce risk in reorganizations or investment in new equipment. More specifically, types of problems benefiting from simulation can be divided into:

- Identifying factors constraining throughput — particularly in high SKU environments where bottlenecks may shift with product mix

- Data-driven decision-making — for example, optimizing the layout of new lines or facilities to minimize material handling and transport distances

- Maximize asset utilization — find the highest ROI from competing approaches

- Communicating ideas — the graphical nature of 3D simulation makes problems and opportunities readily apparent to even non-technical observers

- Minimize WIP or money bound to production – each unfinished product, each part in inventory, each product in the warehouse even each worker not fully utilized is money standing still.

How users benefit from 3D production simulation

It’s extremely difficult to experiment in a production environment. Every test or trial takes time to organize and perform and will almost certainly result in some degree of production stoppage. If the experiment involves rearranging physical assets this can be both expensive and time-consuming.

Simulation enables risk-free experimentation, and by not disrupting existing operations and as a result of the speed the model can run, it allows for more options to be explored. This lets users refine and optimize changes or equipment layouts prior to implementation.

Many users find simulation useful in formulating plans to deal with change. The impact of product mix shifts, new pack formats, or different work schedules can all be evaluated before being introduced. For any management team undertaking contingency planning, simulation is a powerful and effective tool.

Another benefit of simulation is its power to persuade. Everyone knows pictures convey more than words: when those pictures are animated the message is amplified many times over. For anyone trying to explain concepts or sell ideas, simulation helps make clear both what is being proposed and the impact it will have.

Less risk, better ROI

Anyone who has ever wondered if they could improve the organization of a production operation, factory, or warehouse will benefit from 3D production simulation. Better than constructing physical models or complex spreadsheets, simulation provides answers to “what if” questions. It facilitates a deeper understanding of existing operations, supports efforts to optimize processes and layouts, and communicates proposals. Most importantly though, it reduces the risk in trying to improve upon what already exists.

If you’re looking for a tool that will help you model your production operations and determine what changes will yield the biggest ROI, you should be using 3D production simulation. Ask how Visual Components can help.

Read more: What is manufacturing simulation and how it works?

Further reading

Optimizing production lines the smart way with simulation

Manufacturers are always looking for ways to improve, whether it’s increasing throughput, reducing bottlenecks, or making better use of resources. But optimizing production lines can get complicated without the right...

Smarter warehouse planning starts with simulation

How can businesses design warehouses that operate efficiently from day one while keeping labor costs and other expenses in check? The key is smart planning and validation with simulation tools...

Comprehensive guide to input data for 3D manufacturing simulation (examples included)

If you're new to 3D manufacturing simulation, you're in the right place. This comprehensive guide will help you understand the essential input data needed to create effective simulation models. Whether...