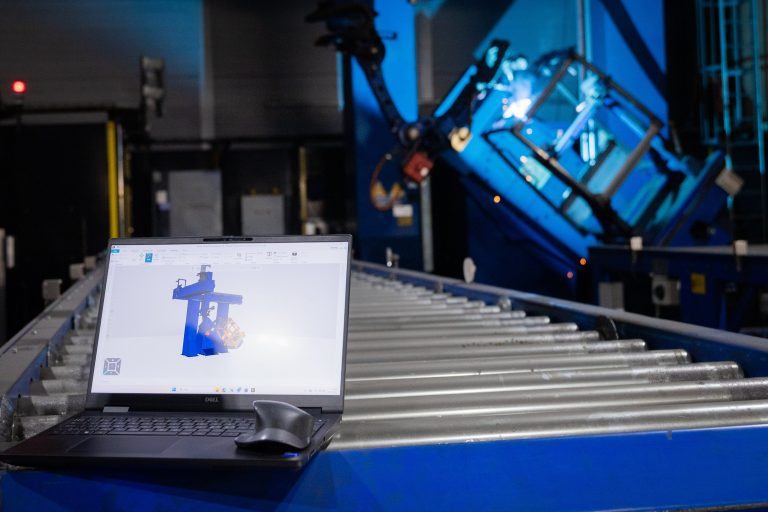

From concept to reality on a more powerful platform.

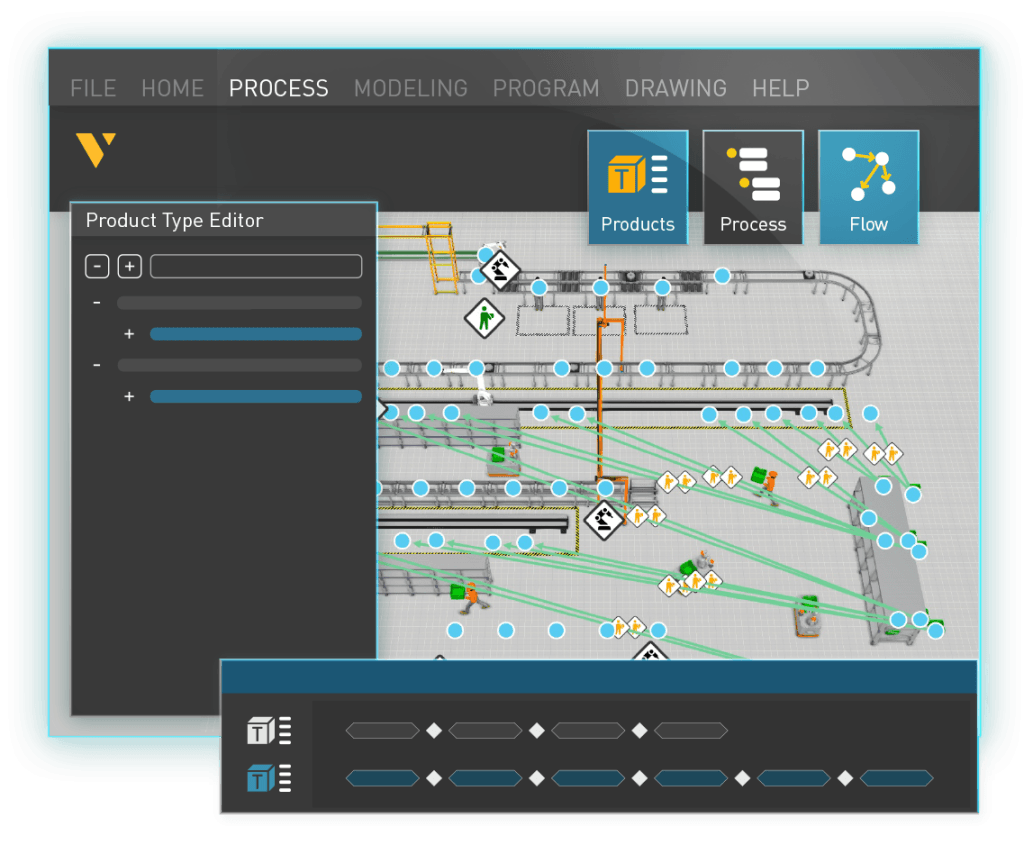

Built for production teams to make manufacturing faster and easier, our platform lets you design factory layouts, simulate production, commission virtually and program robots.

Fastest way from concept to reality.

From the very beginning, we believed there must be a faster, easier and more collaborative way to design manufacturing systems. Today’s increasingly complex industrial landscape has shown that we are on the right path.

Designing new manufacturing processes and systems should be accessible to everybody. Collaborate, share and come to decisions faster, together.

Embrace digital transformation with our products, designed for a wide range of manufacturing professionals, from engineers to production managers. Make smarter decisions at every step of your production process.

We help over 2400 companies make their visions come to life.

Discover why Visual Components is the right choice for you. Learn how different company types, such as manufacturers and system integrators, use our solutions to solve challenges and simulate their next automation projects.

How our customers benefit

Boost your efficiency by up to 30%

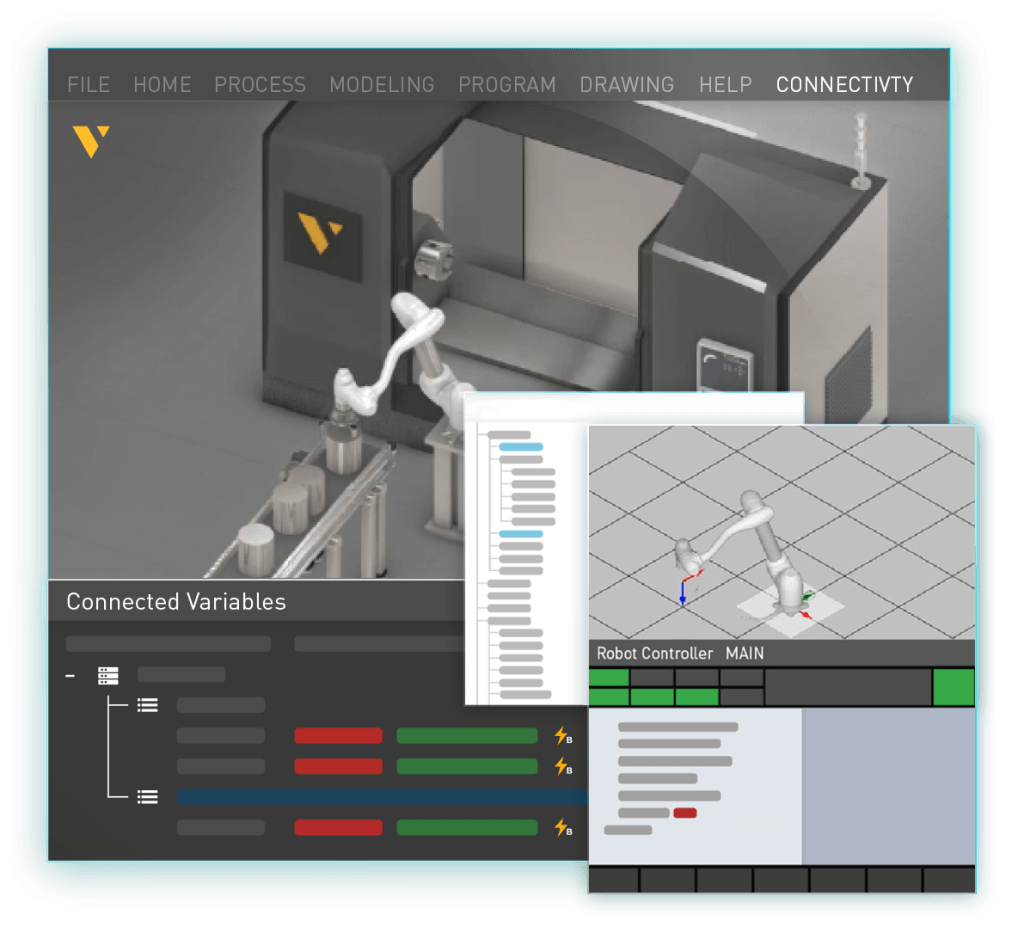

Increase efficiency in your manufacturing operations with our virtual commissioning tools, enabling precise control over process performance through simulation and validation of designs with PLCs and robot controllers.

Save costs by up to 15%

Design many what-if scenarios in hours instead of days, have better insights into your projects, minimize your investment and save additional costs from your projects.

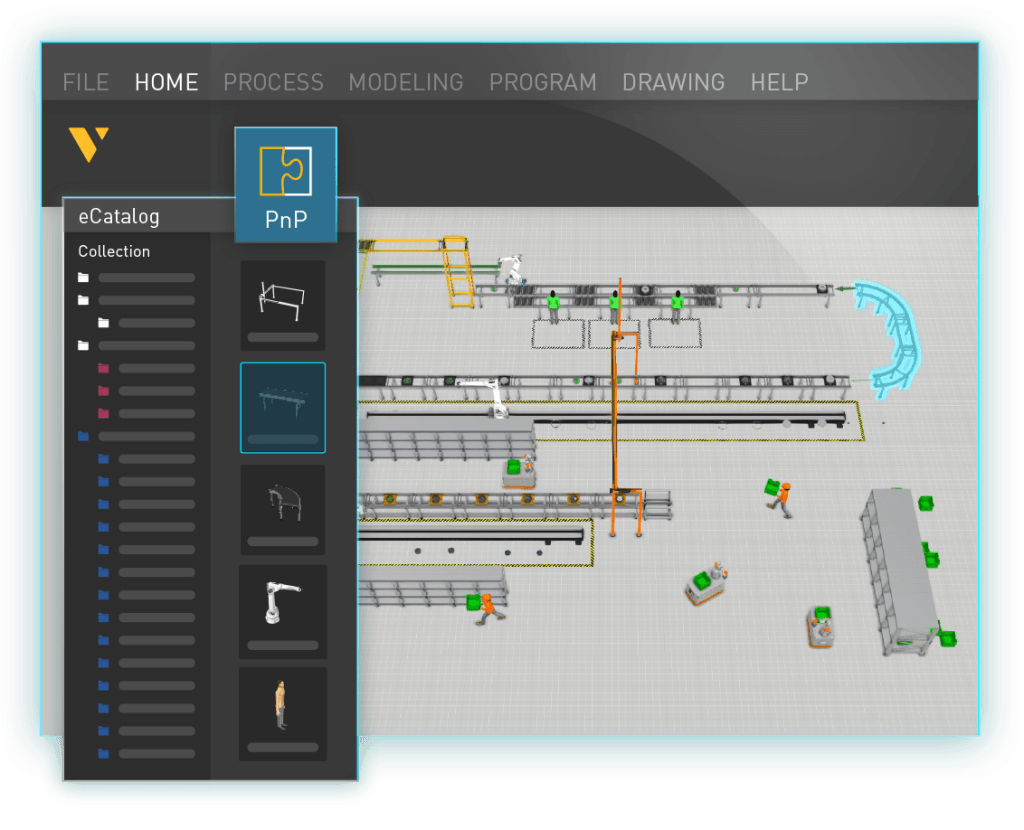

3500+ ready-made CAD components

Use our extensive library of 3D models with more than 1,600 robots, 70+ brands, and a wide range of conveyors, machines, resources, robot tools, factory facilities and more.

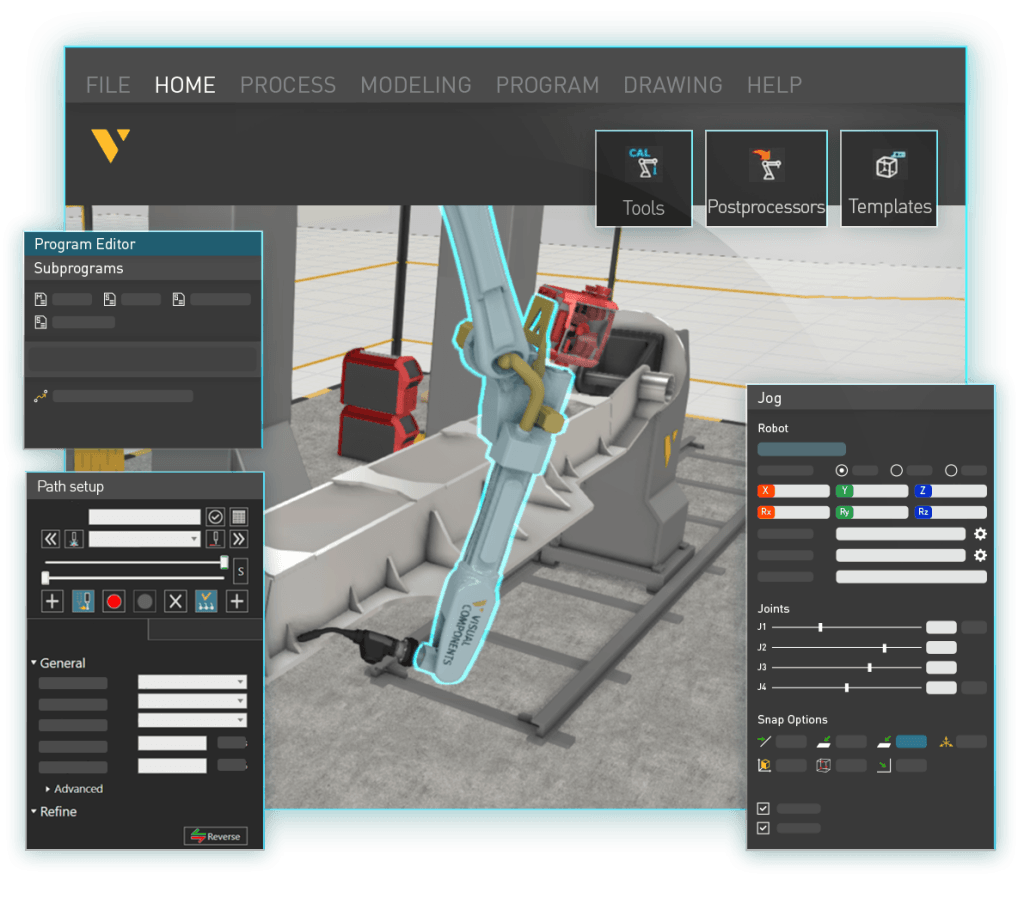

Reduce robot programming time by up to 80%

Program your robots more quickly and efficiently than with traditional manual programming methods. Test and optimize your programs before downloading them to the physical robots.

Maximize robot utilization by up to 95%

Optimize your robots’ utilization with fast and easy offline programming for tasks such as welding, material processing, or spray painting and eliminate robot downtime.

Enhance safety

Reduce the risks of accidents and injuries by programming heavy-duty industrial robots through offline programming software. Program from anywhere without any risk of robot collisions or physical accidents.

What our customers have to say

Discover

Fast and easy robot offline programming (OLP) for welding: a practical no-code workflow

Robot offline programming (OLP) makes robotic welding faster, more predictable and easier to manage, especially in high-mix, low-volume environments. This guide outlines the foundational OLP workflow, covering digital cell setup,…

How offline programming software improves robotic welding efficiency

Offline programming software makes robotic welding more efficient by enabling manufacturers to create and optimize robot programs directly in a digital environment. It supports a wide range of processes including…

Manufacturing experts on why early simulation and people-first automation matter

Earlier this year, Visual Components hosted a roundtable discussion titled “How to Achieve Efficiency in Production,” bringing together Finnish experts from industry and academia to share their insights on how…

Try it yourself

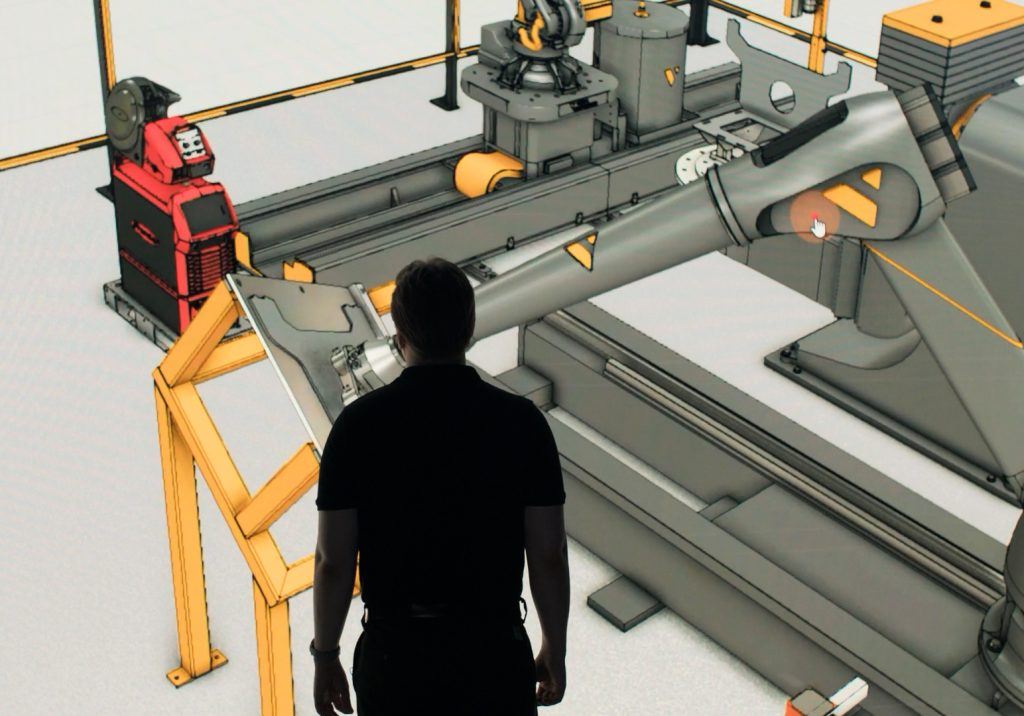

Move around and get up close in the 3D space. With Visual Components, you can effortlessly share your simulations with colleagues and clients, making it easier than ever to demonstrate your ideas and projects.

Other products

Explore our other products, such as Visual Components Experience, which allows you to experience the 3D simulations you’ve designed with Visual Components on mobile devices, virtual reality, and the web—just like the simulations showcased above!

Explore our eCatalog

The Visual Components eCatalog is an industry-leading library with over 3,000 ready-to-use components. It features a wide range of virtual models, including robots, machines, and equipment from many top brands in industrial automation. Browse through our web eCatalog to see what’s included.